Boron nitride-silver/cellulose composite material and preparation method thereof

A composite material, boron nitride technology, applied in the field of boron nitride-silver/cellulose composite material and its preparation, can solve problems such as Ag conductivity hindrance, achieve increased mechanical properties, reduce interface thermal resistance, and excellent flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

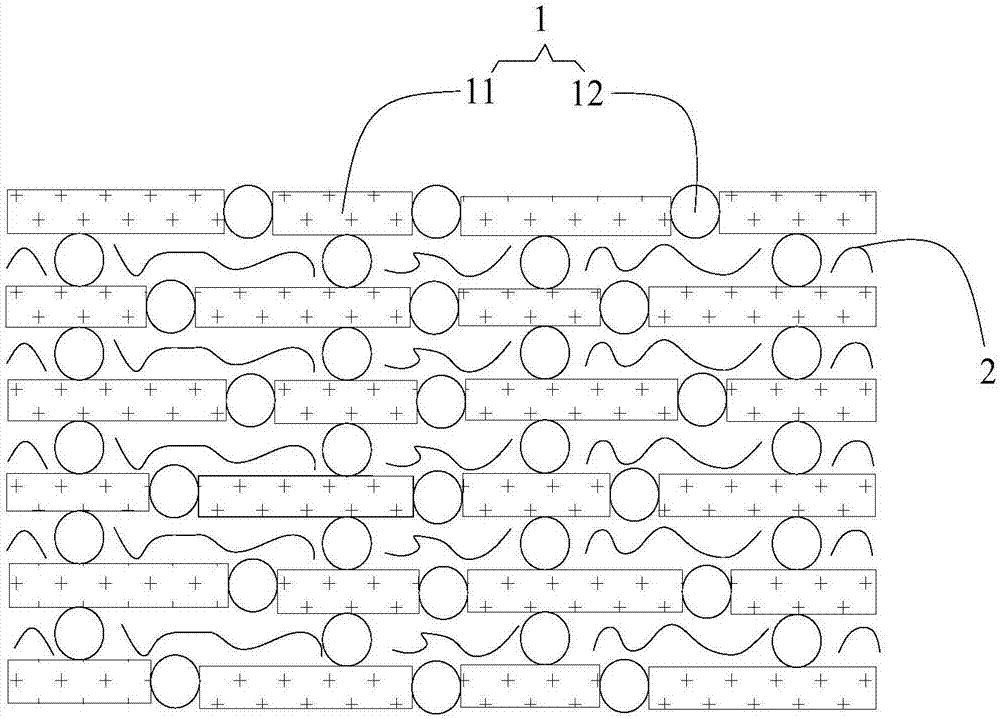

Image

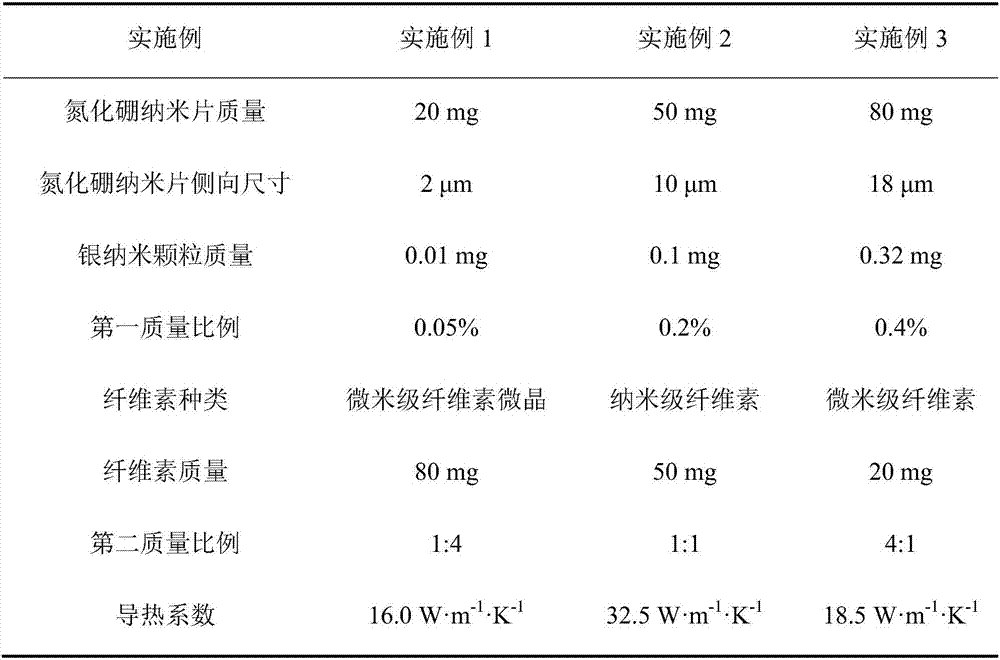

Examples

preparation example Construction

[0034] The present invention also provides the preparation method of above-mentioned boron nitride-silver / cellulose composite material, comprises the following steps:

[0035] S1. Mixing boron nitride nanosheets, silver source and reducing agent, the silver ions in the silver source are reduced to obtain silver nanoparticles, and the silver nanoparticles bridge at least two boron nitride nanosheets in the horizontal direction nanosheets to obtain boron nitride-silver hybrid fillers.

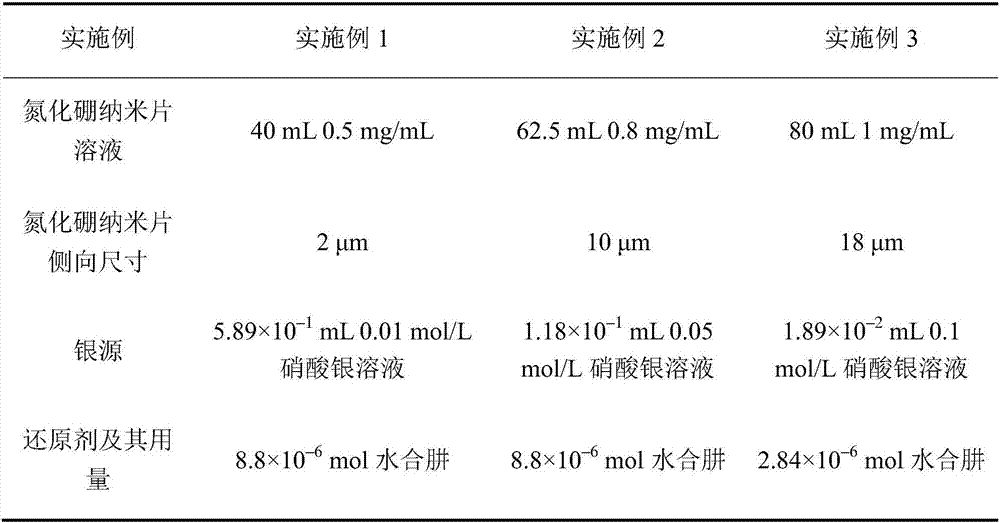

[0036] The preparation process of the boron nitride-silver hybrid filler is preferably a liquid phase reduction method.

[0037] Specifically, the method includes the following steps: (1) adding boron nitride powder into an organic solvent, centrifuging after uniform dispersion, and taking the upper liquid to obtain a boron nitride nanosheet solution; (2) adding boron nitride powder The nanosheet solution is cooled down to 10°C-15°C while stirring, and silver source is gradually added; (3) The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com