Integrated full perovskite solar energy cell and LED display system and manufacturing method thereof

A technology of solar cells and integrated systems, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of single crystal silicon time-consuming and energy-consuming, complex production process, and high difficulty in commercial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

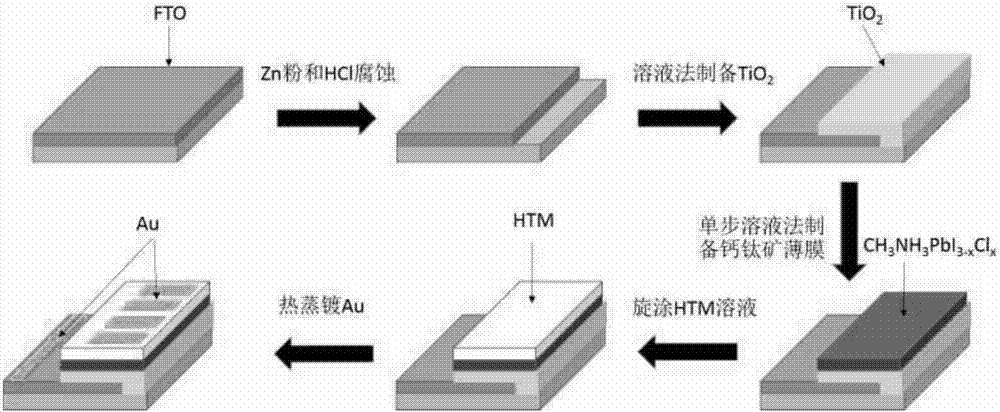

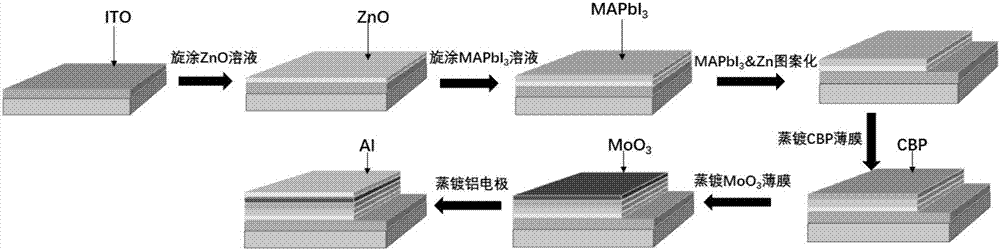

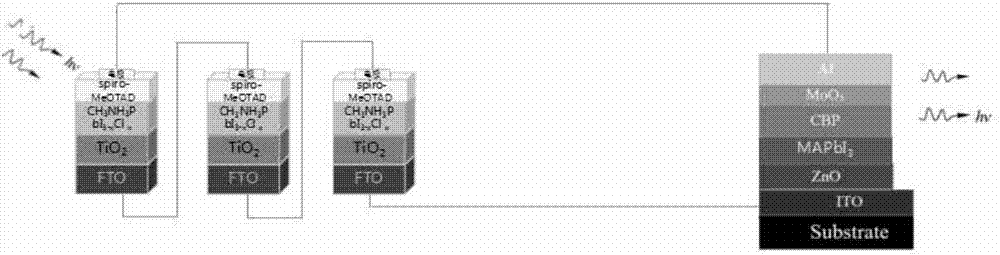

[0053] In this embodiment, see image 3 with Figure 4 , An all-perovskite solar cell and LED display integrated system, characterized in that: the solar cell 1 and the LED display device 2 are assembled to form an integrated system, and the solar cell 1 is a solar cell device using a planar perovskite film, The LED display device 2 uses a perovskite film as the luminescent material layer, and connects the anode of the perovskite solar cell 1 and the cathode of the LED display device 2 in series through wires, and connects the cathode substrate of the perovskite solar cell 1 and The anode substrates of the LED display device 2 are connected in series to form a closed loop. The solar cell 1 absorbs solar energy and emits electric energy to supply power to the LED display device 2.

[0054] In this embodiment, see image 3 The solar cell 1 sequentially consists of an anode substrate, a titanium dioxide window layer, a perovskite film layer, a hole transport layer film and a cathode ...

Embodiment 2

[0087] This embodiment is basically the same as the first embodiment, and the special features are:

[0088] In this embodiment, in an all-perovskite solar cell and LED display integrated system, a hole blocking layer is also provided between the light-emitting layer of the perovskite film and the hole transport layer of the CBP film.

[0089] In this embodiment, when the LED display device is prepared in step b of preparing an all-perovskite solar cell and LED display integrated system, and MAPbI is prepared in step (c) of step ⑶ 3 After the film is deposited, the substrate device prepared in step (c) is then transferred to the multi-source vapor deposition system, and the chamber pressure of the multi-source vapor deposition system is controlled to be 5x10- 3 Pa, adjust the temperature of the corresponding evaporation source, make the TPBI material reach the sublimation point, and deposit on MAPbI in gaseous state 3 On the film, a dense TPBI film is formed as a hole blocking layer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com