Sunscreen lotion and preparation method thereof

A solution and composition technology, applied in the field of sunscreen liquid and its preparation, can solve the problems of high price of waterproof products, dissolution and shedding of sunscreen components, skin irritation, etc., achieve lasting and effective sunscreen ability, realize care and repair, and reduce skin irritation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

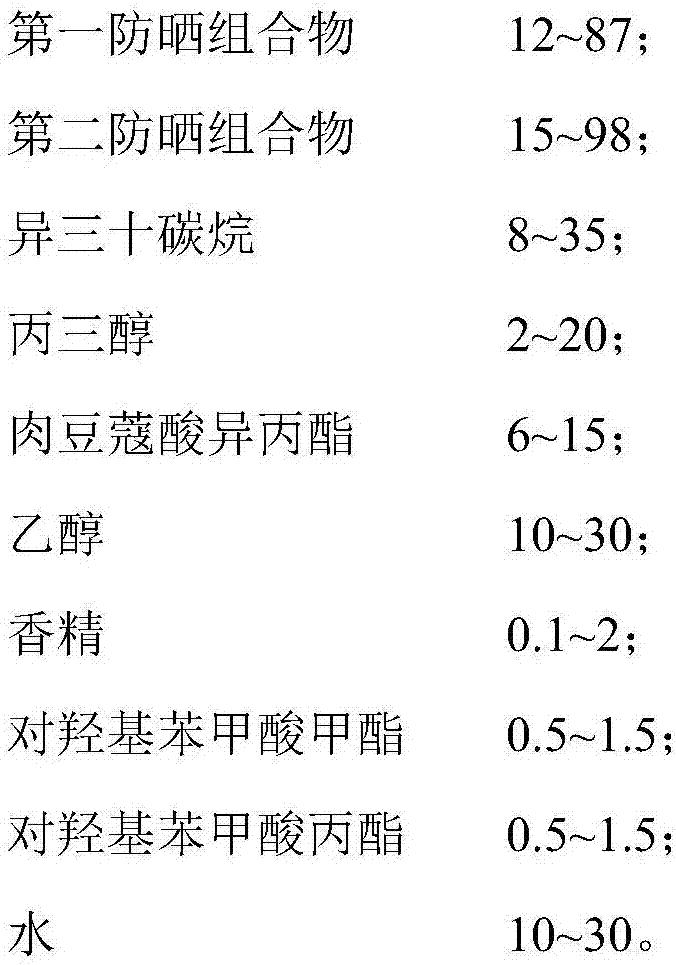

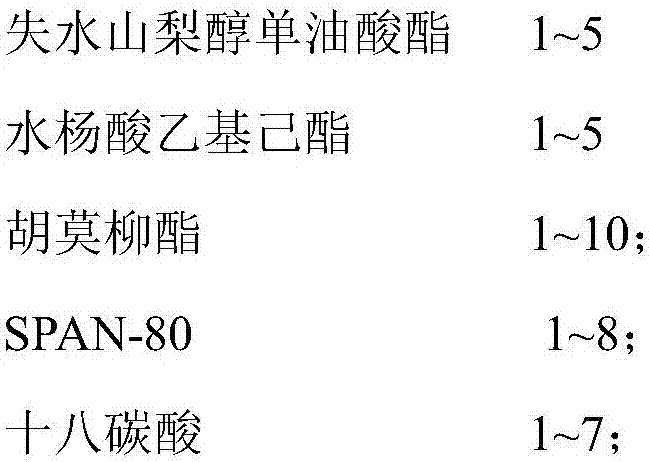

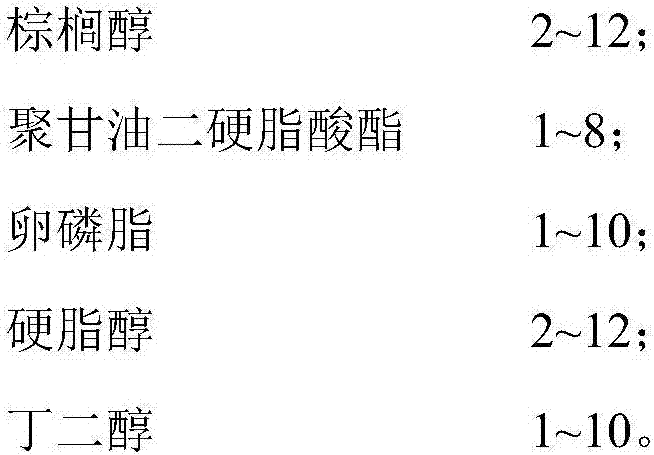

Method used

Image

Examples

Embodiment 1

[0030] First, heat 16 grams of water to 75°C, add 1 gram of sorbitan monooleate, 1 gram of ethylhexyl salicylate, 2 grams of homosalate, 3 grams of SPAN-80, ten Octacarbonic acid 1g, palmitic alcohol 2g, polyglyceryl distearate 2g, lecithin 1g, stearyl alcohol 2g, butylene glycol 1g. Stirring was continued until all dissolved and a transparent solution was obtained. Raise the temperature to 80°C, and then add the following ingredients in sequence: 1 g of phenyl benzimidazole sulfonic acid, 2 g of disodium phenyl dibenzimidazole tetrasulfonate, and 1 g of ethylhexyl methoxycinnamate , 2 grams of isoamyl p-methoxycinnamate, 1 gram of phenylbenzimidazole sulfonic acid, 1.5 grams of bis-ethylhexylphenol methylaminobenzazine, 1 gram of 4-methylbenzylidene camphor, PEG -25 p-aminobenzoic acid 2g, isoamyl alcohol trimethoxycinnamate trisiloxane 1g, ethylhexyl triazone 2g, pentyl dimethyl-p-aminobenzoic acid 1g, diethyl Aminohydroxybenzoylhexylbenzoate 2g, Methylene bis-benzotriazol...

Embodiment 2

[0034] First, heat 25 grams of water to 78°C, add 2 grams of sorbitan monooleate, 2 grams of ethylhexyl salicylate, 5 grams of homosalate, 4 grams of SPAN-80, ten Octacarbonic acid 3 grams, palmitic alcohol 7 grams, polyglyceryl distearate 4 grams, lecithin 5 grams, stearyl alcohol 7 grams, butylene glycol 5 grams. Stirring was continued until all dissolved and a transparent solution was obtained. Raise the temperature to 83°C, and then add the following ingredients in sequence: 4 grams of phenyl benzimidazole sulfonic acid, 5 grams of disodium phenyl dibenzimidazole tetrasulfonate, 4 grams of ethylhexyl methoxycinnamate , 3.5 grams of isoamyl p-methoxycinnamate, 2.5 grams of phenylbenzimidazole sulfonic acid, 2.5 grams of bis-ethylhexylphenol methylaminobenzazine, 2 grams of 4-methylbenzylidene camphor, PEG -25 p-aminobenzoic acid 5 grams, isoamyl alcohol trimethoxycinnamate trisiloxane 2 grams, ethylhexyl triazone 4 grams, pentyl dimethyl p-aminobenzoic acid 3 grams, diethy...

Embodiment 3

[0038] First, heat 10 grams of water to 70°C, add 1 gram of sorbitan monooleate, 1 gram of ethylhexyl salicylate, 1 gram of homosalate, 1 gram of SPAN-80, ten Octacarbonic acid 1g, palmitic alcohol 2g, polyglyceryl distearate 1g, lecithin 1g, stearyl alcohol 2g, butylene glycol 1g. Stirring was continued until all dissolved and a transparent solution was obtained. Raise the temperature to 75°C, and then add the following ingredients in sequence: 1 g of phenylbenzimidazole sulfonic acid, 1 g of disodium phenyl dibenzimidazole tetrasulfonate, and 1 g of ethylhexyl methoxycinnamate , 1 g of isoamyl p-methoxycinnamate, 1 g of phenylbenzimidazole sulfonic acid, 1 g of bis-ethylhexylphenol methylaminobenzazine, 1 g of 4-methylbenzylidene camphor, PEG -25 p-aminobenzoic acid 1 g, isoamyl alcohol trimethoxycinnamate trisiloxane 1 g, ethylhexyl triazone 1 g, pentyl dimethyl p-aminobenzoic acid 1 g, diethyl Aminohydroxybenzoyl hexyl benzoate 1 g, methylene bis-benzotriazolyl tetrameth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical indicatrix | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com