Milking sow fodder additive and preparation method and application thereof

A feed additive and technology for lactating sows, which are applied in the field of feed additives for lactating sows and their preparation, can solve problems such as economic loss, poor growth and development, and aggravation of disease in livestock pig breeding, and achieve improved intestinal digestion and immunity. , the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

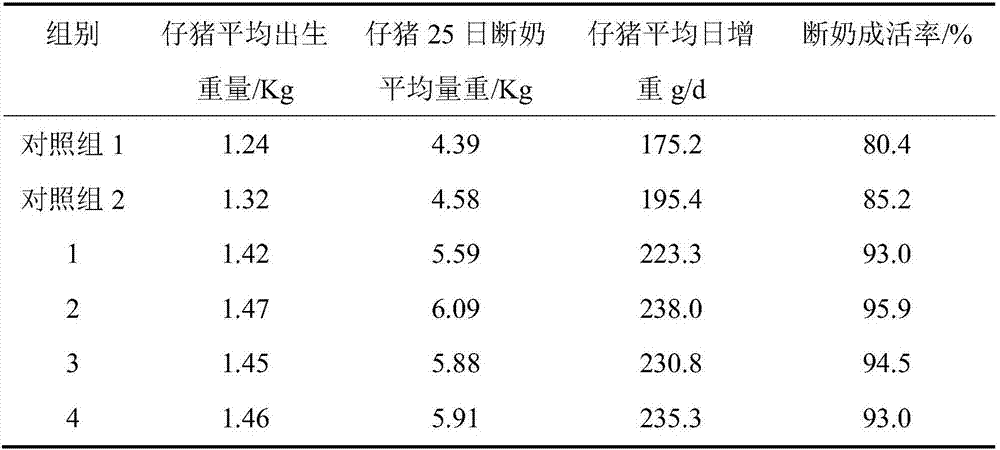

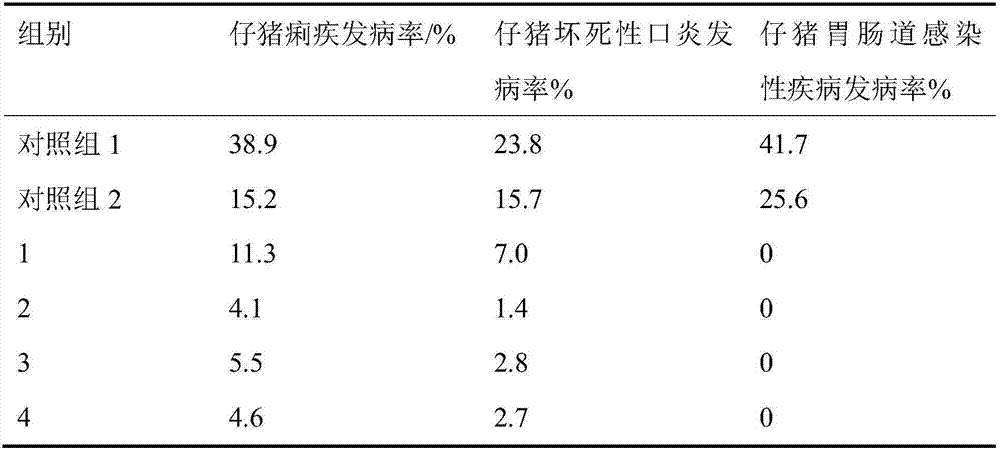

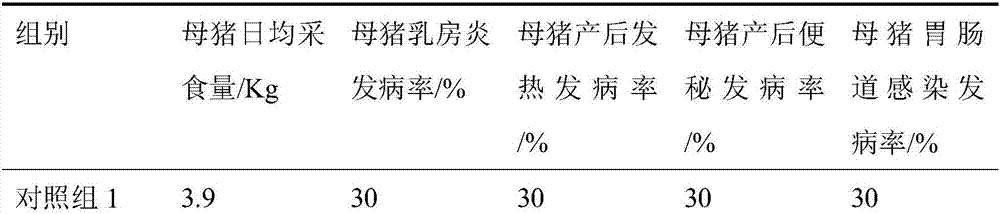

Examples

Embodiment 1

[0034] Party:

[0035] 10 parts of Baihutang granules, 7 parts of Wang Buliu Xing, 4 parts of Tongcao, 4 parts of Loulu, 2 parts of Suanzaoren, 8 parts of Amomum, 2 parts of Tangerine Peel, 2 parts of Fructus Aurantii, 8 parts of Purslane; Baihutang granules are prepared from 30 parts of raw gypsum, 3 parts of honey-roasted licorice, 9 parts of Anemarrhena anemarrhena and 15 parts of japonica rice.

[0036] Preparation:

[0037] (1) Weigh the raw materials used, decoct the raw gypsum for 0.5h first, then add honey-roasted licorice, Anemarrhena anemarrhena, and japonica rice three herbs, decoct for 1.5h, filter to get the filtrate, centrifuge the filtrate to get the supernatant, concentrate to a relative density of 1.20 thick extract, adding pharmaceutical excipients starch, dextrin, α-lactose, wherein the mass percentages of Baihutang thick extract, starch, dextrin and α-lactose are 40.00%, 42.14%, 10.00%, 7.86%; granules, and dried to obtain Baihutang granules;

[0038](2)...

Embodiment 2

[0041] Party:

[0042] 12 parts of Baihu Tang Granules, 8 parts of Wang Buliu Xing, 5 parts of Tongcao, 5 parts of Loulu, 3 parts of Suanzaoren, 10 parts of Amomum, 3 parts of Tangerine Peel, 3 parts of Aurantium Fructus, 9 parts of Purslane; Baihutang granules are prepared from 30 parts of raw gypsum, 3 parts of honey-roasted licorice, 9 parts of Anemarrhena anemarrhena and 15 parts of japonica rice.

[0043] Preparation:

[0044] (1) Weigh the raw materials used, decoct the raw gypsum for 0.8h, then add honey-roasted licorice, Anemarrhena anemarrhena, and japonica rice three herbs, decoct for 1.3h, filter to get the filtrate, centrifuge the filtrate to get the supernatant, concentrate to a relative density of 1.15 Thick extract, adding pharmaceutical excipients starch, dextrin, α-lactose, wherein the mass percentages of Baihutang thick extract, starch, dextrin and α-lactose are 40.00%, 42.14%, 10.00%, 7.86%; granules, and dried to obtain Baihutang granules;

[0045] (2) D...

Embodiment 3

[0048] Party:

[0049] 8 parts of Baihu Tang Granules, 6 parts of Wangbuliuxing, 3 parts of Tongcao, 3 parts of Loulu, 1 part of Suanzaoren, 5 parts of Amomum, 1 part of Tangerine Peel, 1 part of Fructus Aurantii, 6 parts of Purslane; Baihutang granules are prepared from 30 parts of raw gypsum, 3 parts of honey-roasted licorice, 9 parts of Anemarrhena anemarrhena and 15 parts of japonica rice.

[0050] Preparation:

[0051] (1) Weigh the raw materials used, decoct the raw gypsum for 0.4h first, then add honey-roasted licorice, Anemarrhena anemarrhena, and japonica rice three herbs, decoct for 1.8h, filter to get the filtrate, centrifuge the filtrate to get the supernatant, concentrate to a relative density of 1.25 thick extract, adding pharmaceutical excipients starch, dextrin, α-lactose, wherein the mass percentages of Baihutang thick extract, starch, dextrin and α-lactose are 40.00%, 42.14%, 10.00%, 7.86%; granules, and dried to obtain Baihutang granules;

[0052] (2) Dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com