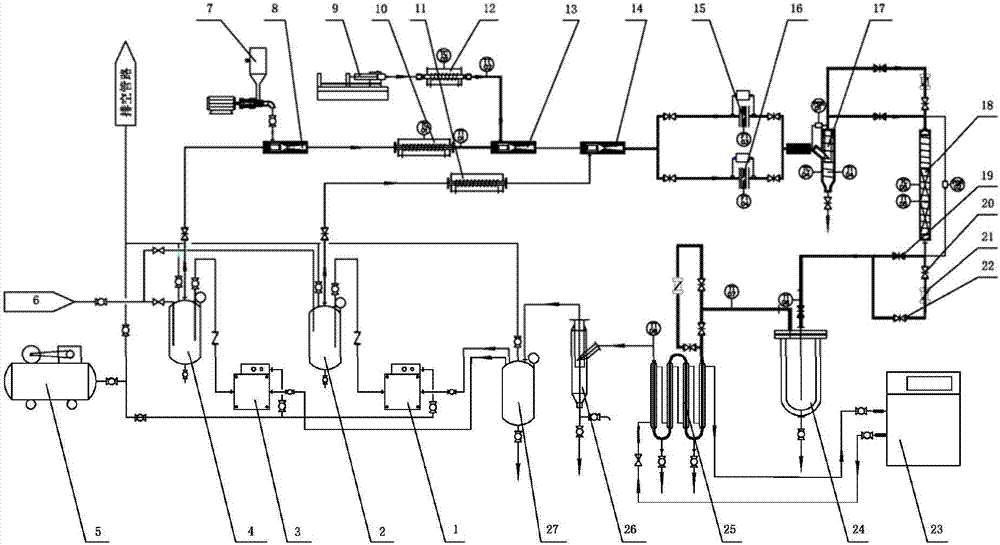

Experimental method and device for step purification of powdered coal pyrolysis high temperature tar containing dusts

An experimental device and tar technology, applied in chemical instruments and methods, combined devices, separation methods, etc., to achieve the effects of improving dust removal efficiency, improving purification capacity, and increasing continuous working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] An experimental method for cascaded purification of high-temperature dust-containing tar from pulverized coal pyrolysis, the method comprising the following steps: feeding dust particles into a screw feeder through a hopper; packing solid filter material particles into a fixed-bed filter; Tar is added to the syringe pump, heated and gasified; nitrogen gas is introduced from the nitrogen bottle to the experimental system and enters the buffer tank; dust enters from the screw feeder, tar gas enters from the syringe pump, and from the buffer tank The incoming nitrogen gas is mixed and enters the cyclone separator, fixed bed filter, and condensation settler three-stage dedusting equipment in turn. The purified mixed gas is cooled by the cooler and the hydrocyclone to separate the purified tar, and the remaining nitrogen gas enters the circuit to continue Recycling; when sampling and measuring the dust removal efficiency of a certain level, open the glass fiber filter membran...

Embodiment 2

[0063] The above-mentioned experimental method for cascade purification of high-temperature dust-containing tar in pulverized coal pyrolysis, the described dust particles are fed into the screw feeder through the hopper, and the sieved experimental dust is weighed, and then added to the screw feeder after recording the mass. The hopper of the feeder, the dust particles are pulverized coal with a diameter of less than 100 μm, and the specific particle size range can be adjusted according to experimental requirements.

Embodiment 3

[0065] The above-mentioned experimental method for cascade purification of high-temperature dust-containing tar in pulverized coal pyrolysis, the described solid filter material particles are filled into the fixed bed filter, and the diameter is 0.38-0.83mm or 0.83-1.25mm or 1.25-2.5 The solid filter material of mm is added to the fixed bed filter, and the thickness of the particle layer of the filter material is controlled to be 5-25 cm. The solid filter material is semi-coke and quartz sand particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com