Preparation method of Z-configuration visible light catalytic decomposing water composite material

A composite material, catalytic decomposition technology, applied in the field of photocatalytic water splitting technology, photocatalysis, and nanocomposite materials, can solve the problems of poor photocatalytic activity and stability, high cost, and achieve good cycle stability, low cost, and improved efficiency. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

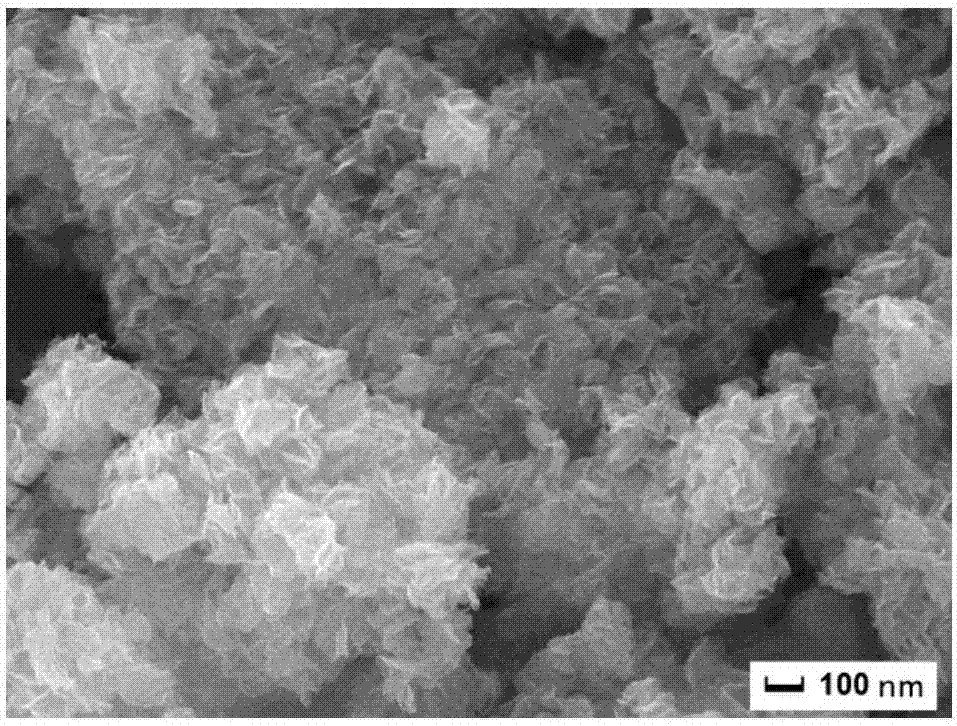

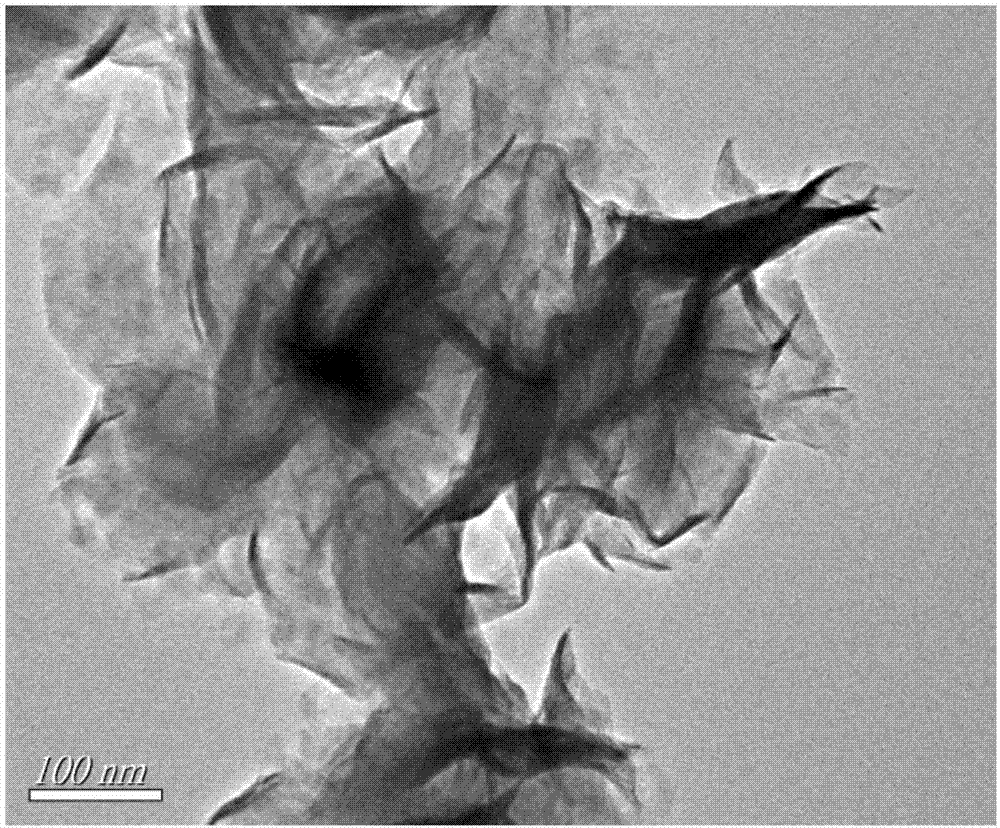

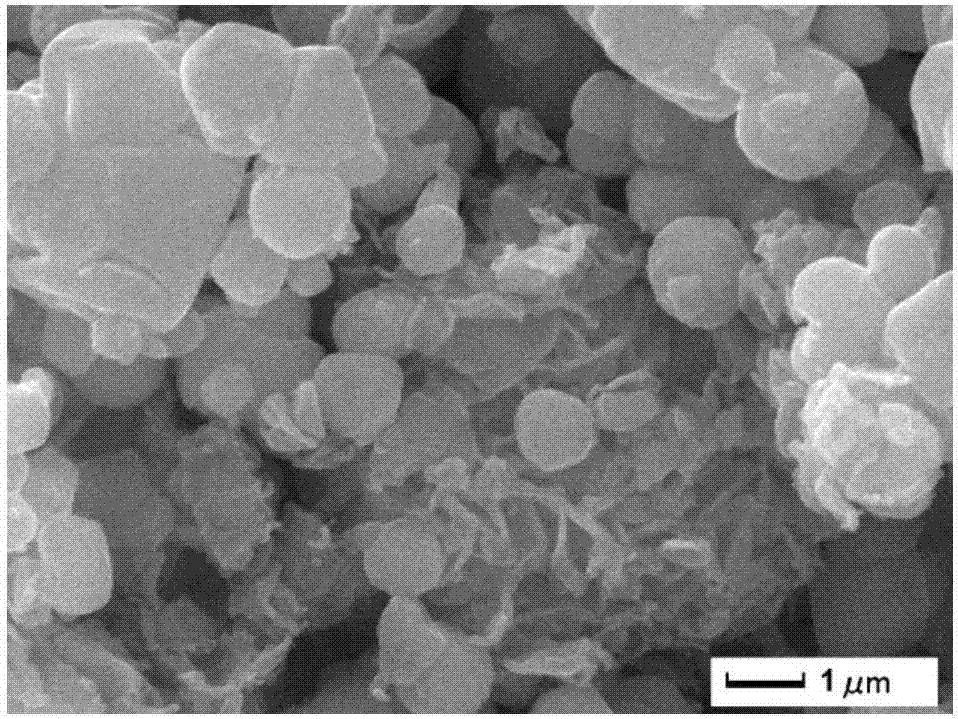

Embodiment 1

[0032] Ultrasonically disperse 20 mg of flower-shaped molybdenum disulfide in 50 mL of deionized water, ultrasonically for 10 minutes to obtain a molybdenum disulfide dispersion, weigh 3.06 g of silver nitrate and dissolve it in 50 mL of distilled water to obtain a silver nitrate solution, and stir it with a magnetic stirrer to Add the configured silver nitrate solution to the flower-shaped molybdenum disulfide dispersion, and stir for 12 hours to obtain a mixed precursor solution; weigh 2.28g of sodium phosphate and dissolve it in 30mL of deionized water to obtain a sodium phosphate solution. Under stirring conditions, the sodium phosphate solution was added dropwise to the mixed precursor solution, and the reaction system gradually became gray-green turbid. After the dropwise addition, the mixed solution continued to stir for 3 hours, and the final product was washed three times with water and washed three times with alcohol.

Embodiment 2

[0034] Ultrasonically disperse 50 mg of flower-shaped molybdenum disulfide in 50 mL of deionized water, ultrasonically for 10 minutes, to obtain a molybdenum disulfide dispersion, weigh 3.06 g of silver nitrate and dissolve it in 30 mL of distilled water to obtain a silver nitrate solution, and stir it with a magnetic stirrer. Add the configured silver nitrate solution to the flower-shaped molybdenum disulfide dispersion, and stir for 12 hours to obtain a mixed precursor solution; weigh 2.28g of sodium phosphate and dissolve it in 30mL of deionized water to obtain a sodium phosphate solution. Under stirring conditions, the sodium phosphate solution was added dropwise to the mixed precursor solution, and the reaction system gradually became gray-green turbid. After the dropwise addition, the mixed solution continued to stir for 3 hours, and the final product was washed three times with water and washed three times with alcohol.

Embodiment 3

[0036] Ultrasonically disperse 100mg of flower-like molybdenum disulfide in 50mL deionized water, ultrasonically for 10 minutes to obtain a molybdenum disulfide dispersion, weigh 3.06g of silver nitrate and dissolve it in 30mL of distilled water to obtain a silver nitrate solution, and stir it with a magnetic stirrer. Add the configured silver nitrate solution to the molybdenum disulfide dispersion, and stir for 12 hours to obtain a mixed precursor solution; weigh 2.28g of sodium phosphate and dissolve it in 30mL of deionized water to obtain a sodium phosphate solution. Next, the sodium phosphate solution was added dropwise to the mixed precursor solution, and the reaction system gradually became gray-green turbid. After the dropwise addition, the mixed solution continued to stir for 3 hours, and the final product was washed three times with water and washed three times with alcohol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com