Yellowing-resisting and low transmittance acrylonitrile-butadiene-styrene/polycarbonate alloy material and preparation method thereof

A technology of polycarbonate and alloy materials, applied in the field of acrylonitrile-butadiene-styrene/polycarbonate alloy materials and its preparation, can solve the problems of ABS low-shading materials such as yellowing and light energy loss, and achieve improved The effects of development success rate, light transmittance reduction, and excellent shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 69 parts of Daqing 750, 10 parts of PC1225Z100, 6 parts of M511, 7 parts of superfine barium sulfate and fine calcium carbonate mixture (the weight ratio of the two = 2:1), 7 parts of R-760, 0.5 parts of light stabilizer (LA- 9440.3 parts, UV-3600.2 parts), 0.5 parts of processing aids (0.3 parts of heat stabilizer, 0.2 parts of lubricant) are mixed evenly by high-speed stirring, and the above-mentioned mixture is sent into the internal mixer machine, under the stirring and shearing of the rotor Fully melted and mixed under the action, and then pressed into 2 mm thin slices by a film laminator, and then cut into pellets with a cutter.

[0051] The temperature of the internal mixer is 220° C., and the rotational speed of the rotor of the internal mixer is 75 rpm.

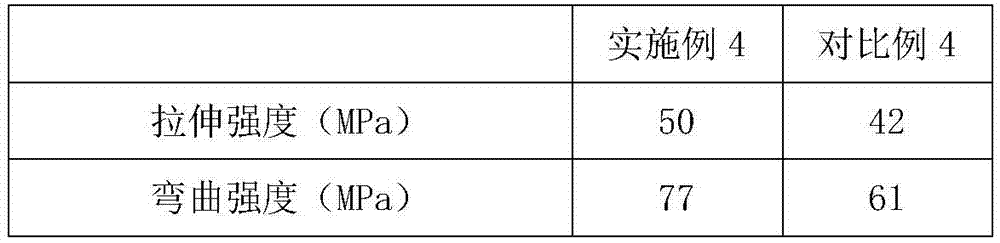

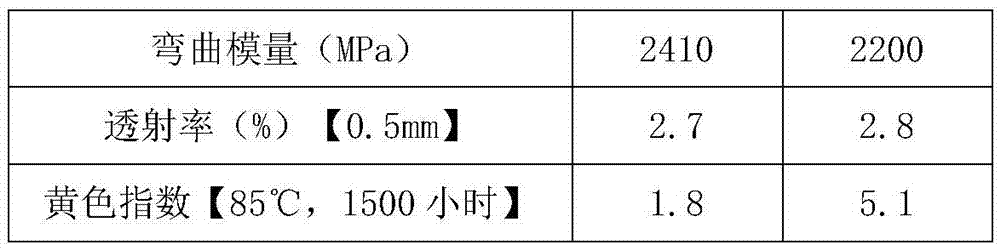

[0052] The prepared material was injection molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 2

[0058] 63 parts of Daqing 750, 10 parts of PC1225Z100, 6 parts of M511, 5 parts of superfine barium sulfate and fine calcium carbonate mixture (both weight ratio = 2:1), 15 parts of R-760, 0.5 parts of light stabilizer (LA- 0.3 part of 944, 0.2 part of UV-360), 0.5 part of processing aid (0.3 part of heat stabilizer, 0.2 part of lubricant) are mixed evenly through high-speed stirring, and the above-mentioned mixture is sent into the internal mixer machine, and the stirring and Under the action of shearing, it is fully melted and mixed, and then pressed into 2 mm thin slices by a film laminator, and then cut into pellets with a cutter.

[0059] The temperature of the internal mixer is 260° C., and the rotational speed of the rotor of the internal mixer is 75 rpm.

[0060] The prepared material was injection molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 3.

Embodiment 3

[0066] 63 parts of Daqing 750, 10 parts of PC1225Z100, 6 parts of M511, 15 parts of ultrafine barium sulfate, 5 parts of R-760, 0.5 parts of light stabilizer (0.3 parts of LA-944, 0.2 parts of UV-360), 0.5 parts of processing aid Parts (0.3 parts of heat stabilizer, 0.2 parts of lubricant) are mixed evenly by high-speed stirring, and the above-mentioned mixture is sent into the internal mixer, fully melted and mixed under the stirring and shearing action of the rotor, and then pressed by the film laminator. into 2 mm thin slices, and then cut into pellets with a cutter.

[0067] The internal mixer temperature is 240° C., and the internal mixer rotor speed is 75 rpm.

[0068] The prepared material was injection molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com