Improved diesel oil hydrocracking catalyst carrier and preparation method thereof

A catalyst carrier and hydrocracking technology, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of average quality of middle distillate oil products, difficulty in the best performance of catalysts, and low catalytic activity of catalysts, etc. Achieve good cracking effect, facilitate rapid transfer, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

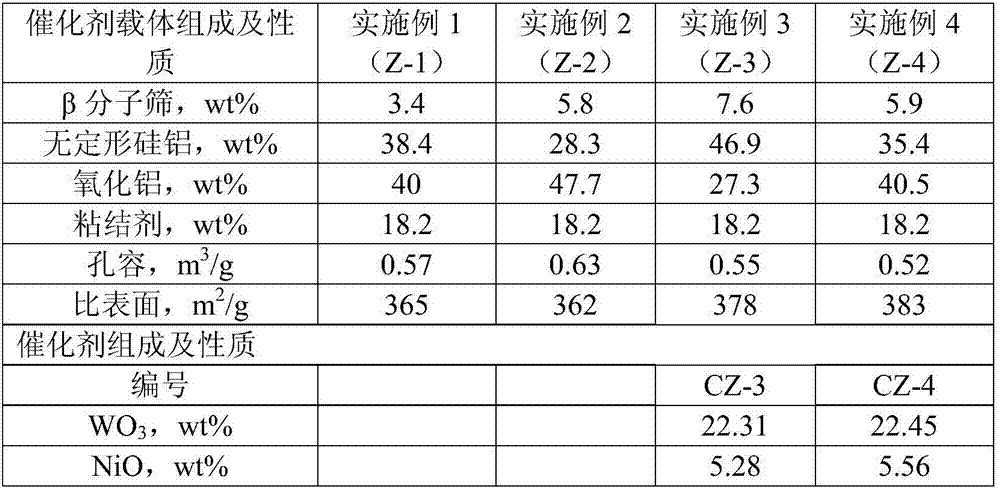

Embodiment 1

[0034] Weigh 201.3g tetraethylammonium bromide (98wt%, technical grade), 27.39g sodium hydroxide, 7.2g pseudo-boehmite (70wt%, technical grade), 870g of water, mix and stir until a clear solution, and then Under constant stirring, add 180g of white carbon black (98wt%, industrial grade) to the solution, and continue to stir to obtain a uniform silica-alumina gel. The silica-alumina gel is dynamically crystallized at 145°C for 7 days, and after solid-liquid separation and After washing and drying, a β molecular sieve was obtained, numbered B1. The main properties of the β molecular sieve are shown in Table 1.

[0035] Add 3000ml aluminum chloride solution (concentration 1.5mol / L) into a 5000ml beaker, add 19g B1 molecular sieve (99% dry basis) into the mixed solution, keep the temperature at 70℃, and continuously add 2mol / L ammonia until the pH is 4 , Evaporate at 80℃ (the evaporation temperature can be 50~90℃), dry the sucked white solid at 100℃ for 3 hours, and calcinate at 500℃...

Embodiment 2

[0038] Weigh 201.3g tetraethylammonium bromide (98wt%, technical grade), 27.39g sodium hydroxide, 7.2g pseudo-boehmite (70wt%, technical grade), 870g of water, mix and stir until a clear solution, and then Under constant stirring, add 180g of white carbon black (98wt%, industrial grade) to the solution, and continue to stir to obtain a uniform silica-alumina gel. The silica-alumina gel is dynamically crystallized at 145°C for 7 days, and after solid-liquid separation and After washing and drying, a β molecular sieve was obtained, numbered B1. The main properties of the β molecular sieve are shown in Table 1.

[0039] Add 3000ml aluminum chloride solution (concentration 1.5mol / L) into a 5000ml beaker, add 28g B1 molecular sieve (99% on dry basis) into the mixed solution, keep the temperature at 70℃, and continuously add 2mol / L ammonia until the pH is 4.3 , Evaporate at 85°C, dry the sucked white solid at 100°C for 3 hours, and calcinate at 500°C for 4 hours to obtain 276.2g of mol...

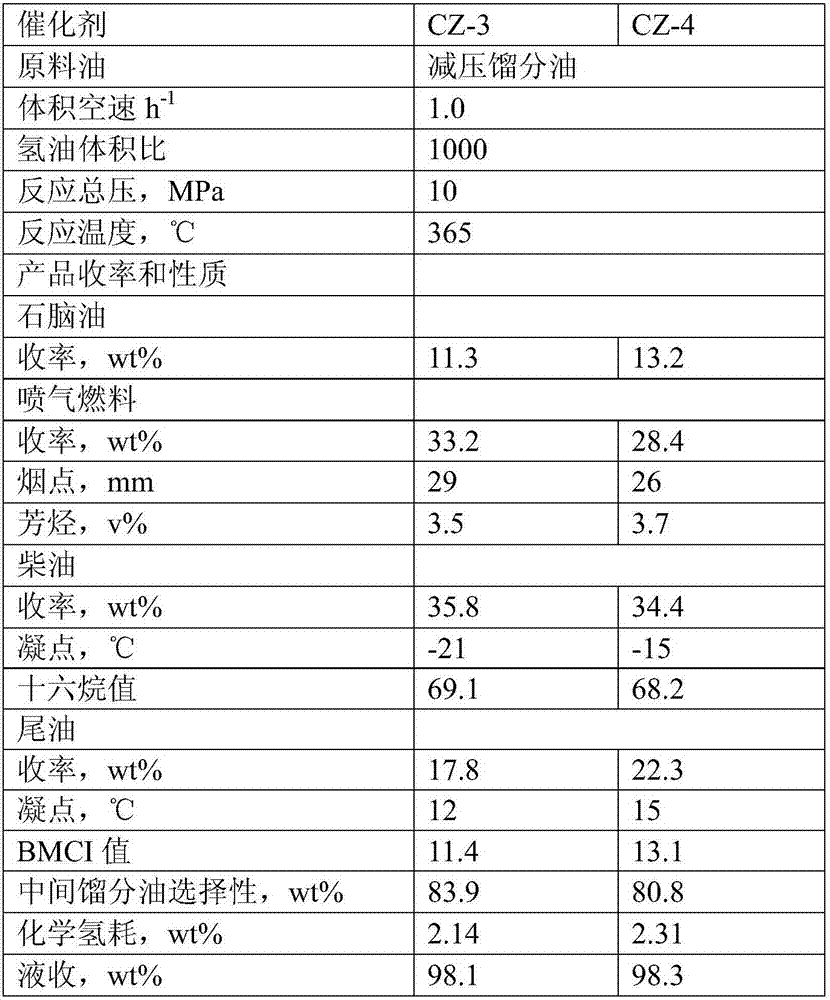

Embodiment 3

[0042] Weigh 185.3g tetraethylammonium bromide (98wt%, technical grade), 22.65g sodium hydroxide, 10.3g pseudo-boehmite (70wt%, technical grade), 870g water, mix and stir until a clear solution, and then Add 180g of white carbon black (industrial grade) to the solution under constant stirring, and continue to stir to obtain a uniform silica-alumina gel. The silica-alumina gel is dynamically crystallized at 145°C for 7 days, after solid-liquid separation, washing and drying A β molecular sieve was obtained, numbered B2. The main properties of the β molecular sieve are shown in Table 1.

[0043] Add 3000ml aluminum chloride solution (concentration 1.5mol / L) into a 5000ml beaker, add 60.5g B2 molecular sieve (99% dry basis) into the mixed solution, keep the temperature at 70℃, and continuously add 2mol / L ammonia until the pH is 4. Evaporate at 85°C, dry the sucked white solid at 100°C for 3 hours, and calcinate at 500°C for 4 hours to obtain 296.4g of molecular sieve and alumina com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com