Multi-sensitive soybean protein isolate-sodium alginate compound hydrogel bead, and preparation and application thereof

A technology of soybean protein isolate and sodium alginate, which is applied in the field of soybean protein isolate composite materials, can solve problems such as complex preparation process, achieve good swelling performance, increase drug loading and encapsulation efficiency, and good swelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

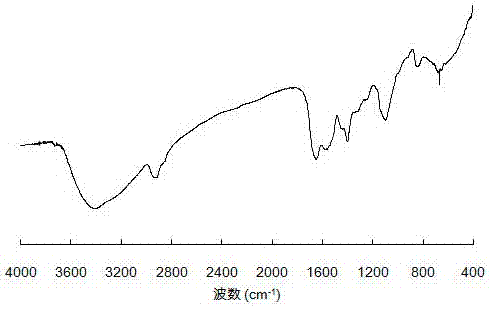

[0043] (1) Take a certain amount of soybean protein isolate and disperse it in 1.5mol / L NaOH solution to obtain a soybean protein isolate dispersion with a content of 0.01g / mL.

[0044] (2) Take 10mL of soybean protein isolate dispersion (containing 0.1g of soybean protein isolate), add 5mL of sodium alginate aqueous solution (concentration: 0.01g / mL, containing 0.05g of sodium alginate) to it, stir and mix evenly at room temperature to obtain Soy Protein Isolate / Sodium Alginate Blend.

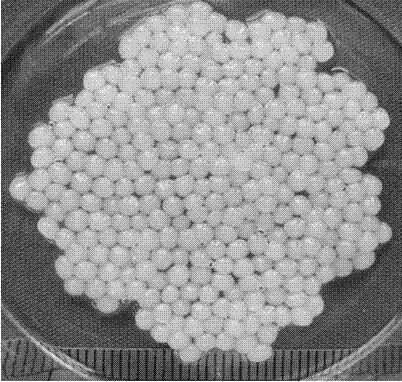

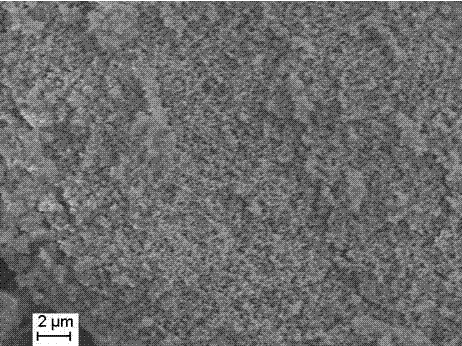

[0045] (3) Slowly drip the mixture of soybean protein isolate / sodium alginate into 50mL of calcium chloride methanol solution (concentration: 0.1mol / L) and let it stand for 80 min; then add 20mL of sodium hexametaphosphate aqueous solution (concentration 1 mmol / L, containing sodium hexametaphosphate 0.0184g), pour off the solvent after the cross-linking reaction at room temperature for 50 minutes, separate the gel beads, and wash with distilled water until the eluate is neutral, dry the free w...

Embodiment 2

[0048] (1) Take a certain amount of isolated soybean protein and disperse it into a KOH solution with a concentration of 1.5 mol / L to obtain a soybean protein isolate dispersion with a content of 0.05 g / mL.

[0049] (2) Take 10mL of soybean protein isolate dispersion (containing 0.5g of soybean protein isolate), add 5mL of sodium alginate aqueous solution (concentration: 0.1 g / mL, containing 0.5g of sodium alginate), and stir and mix evenly at room temperature to obtain Soy Protein Isolate / Sodium Alginate Blend.

[0050] (3) Slowly instill the soybean protein isolate / sodium alginate mixture into 25 mL of calcium chloride in methanol solution (concentration 0.7 mol / L), and let it stand for 20 min; then add 15 mL of sodium hexametaphosphate aqueous solution (concentration 10 mmol / L, containing 0.0918g sodium hexametaphosphate), after the cross-linking reaction at room temperature for 10 minutes, the solvent was poured out, the gel beads were separated, and washed with distilled ...

Embodiment 3

[0053] (1) Take a certain amount of isolated soybean protein and disperse it into a NaOH solution with a concentration of 1.0mol / L to obtain a soybean protein isolate dispersion with a content of 0.1g / mL.

[0054] (2) Take 10mL of soybean protein isolate dispersion (containing 1g of soybean protein isolate), add 40mL of sodium alginate aqueous solution (concentration: 0.05 g / mL, containing 2g of sodium alginate), and stir and mix evenly at room temperature to obtain soybean isolate protein / sodium alginate mixture.

[0055] (3) Slowly drip the soybean protein isolate / sodium alginate mixture into 40mL calcium chloride methanol solution (concentration 0.4mol / L), let it stand for 50 min; then add 30mL containing 1-ethyl-3- Aqueous solution of (3-dimethylaminopropyl) carbodiimide hydrochloride (concentration 5 mmol / L, containing 0.0288 g of cross-linking agent), after cross-linking reaction at room temperature for 30 minutes, the solvent was poured out, and the gel beads were separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com