A kind of low-carbon ferrophosphorus for non-oriented silicon steel and its smelting method

A technology of oriented silicon steel and smelting method, which is applied in the field of smelting technology, can solve problems such as limitation, uncontrollable harmful components, and deterioration of electromagnetic properties of non-oriented silicon steel, and achieve the effects of stable chemical composition, improved electromagnetic properties, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

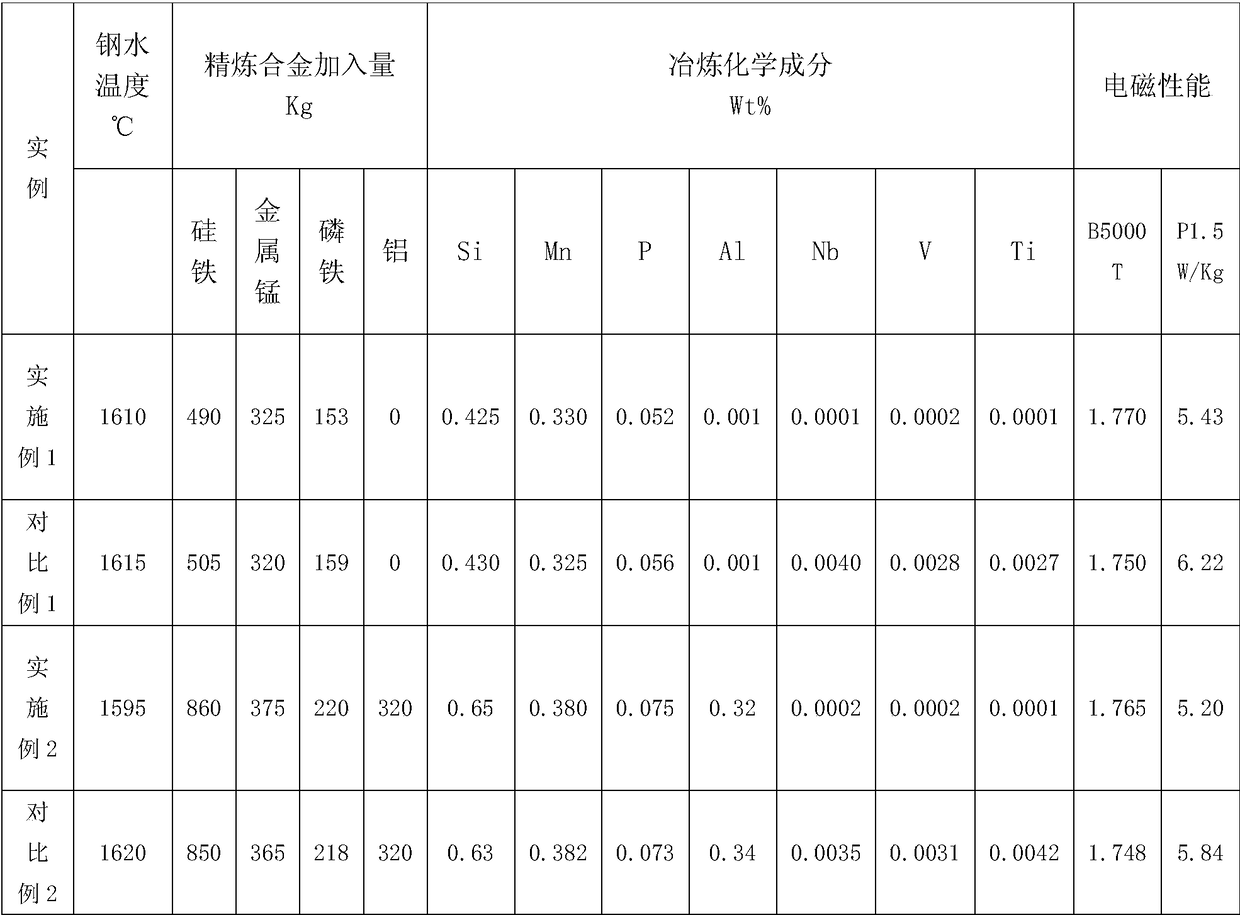

Examples

Embodiment Construction

[0030] Embodiment A 2400 kVA closed mine electric furnace is used, and special phosphorus cooling equipment is used for gas filtration and purification to smelt low-carbon ferrophosphorus with a content of 30%. The quality requirements and particle size of apatite: coke: silica: iron filings shall be controlled in accordance with the provisions in the technical plan; the chemical composition of apatite: coke: silica stone: iron filings shall meet the composition control quality requirements specified in the technical plan.

[0031] The low-carbon ferrophosphorus raw material is mixed according to the ratio of apatite: coke: silica: iron filings = 100:16:26:42 to form a charge.

[0032] The mixed charge is continuously loaded into the electric furnace from the high-level silo along the material pipe, and the smelting production starts after the charge is full.

[0033] Produce a certain amount of ferroalloy water for about two hours, then start to release the molten iron in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com