Preparation method of a sprayable and durable anti-icing superamphiphobic coating

A super-amphiphobic, anti-icing technology, used in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of not lasting anti-icing, reducing the adhesion strength of ice on the surface, and difficult to remove the surface, etc. Achieve durable icing resistance, good durability and firmness, and improved bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

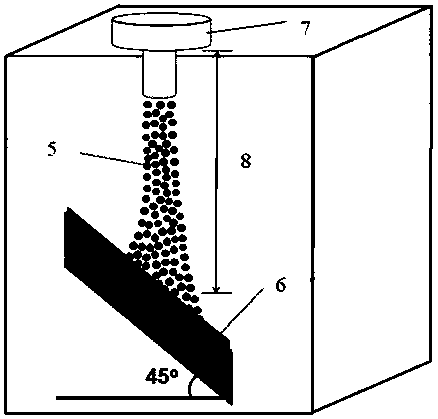

Method used

Image

Examples

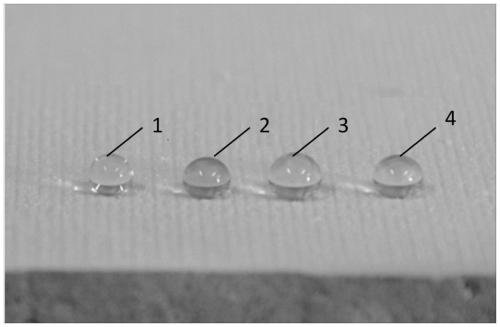

Embodiment 1

[0055] In this embodiment, the base material is an aluminum alloy plate with a thickness of about 200*200*3mm. The aluminum alloy plate can be Shanghai Zhixin Industry and Trade Co., Ltd.-2014 type, a super amphiphobic aluminum alloy that can resist freezing for a long time The plate preparation method is carried out as follows:

[0056] (1) The aluminum alloy plate is used as the substrate, cleaned with water and a clean cotton cloth, and then the surface of the substrate is roughened by sandblasting with 80 mesh brown corundum sand, the air pressure is 0.5MPa, and the sandblasting time is 1 minute; then use Acetone, ethanol and deionized water are used to clean the surface of the substrate in sequence, and dry at room temperature for use;

[0057] (2) 10 g of one-component polyurethane adhesive (Great Wall brand 717 one-component polyurethane adhesive, Shanghai Fine Stationery Co., Ltd.) was ultrasonically dissolved in 50 mL of acetone, 30 mL of xylene, and 20 mL of tert-but...

Embodiment 2

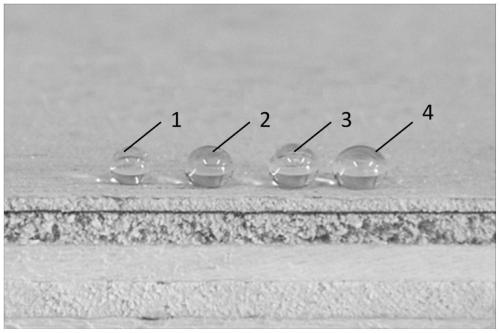

[0087] In this embodiment, the base material is a poplar board with a thickness of about 200*200*15mm, and the preparation method of a super amphiphobic poplar board that can resist freezing for a long time is carried out as follows:

[0088] (1) The poplar board is used as the substrate, cleaned with water and clean cotton cloth, and then the surface of the substrate is roughened by sandblasting with 200 mesh brown corundum sand, the air pressure is 2.0MPa, and the sandblasting time is 30s; after that, use acetone, Wash the substrate surface with ethanol and deionized water in sequence, and dry it at room temperature for use;

[0089] (2) 8g of one-component polyurethane adhesive (Heshibao one-component polyurethane adhesive, Dongguan New Vision Technology Co., Ltd.) was ultrasonically dissolved with stirring in a mixed solvent of 50mL acetone, 35mL toluene, and 15mL ethyl acetate to prepare Polyurethane glue;

[0090] (3) Weigh 2.4g of hydrophilic fumed silica with a partic...

Embodiment 3

[0108] In this embodiment, the substrate material is corrugated cardboard with a thickness of about 200*200*5 mm, and the preparation method of super amphiphobic corrugated cardboard that can resist freezing for a long time is carried out according to the following steps:

[0109] (1) Corrugated cardboard is used as the base material, wipe it clean with a clean cotton cloth, and set aside;

[0110] (2) 5g of one-component polyurethane adhesive (Great Wall brand 718 one-component polyurethane adhesive, Shanghai Fine Stationery Co., Ltd.) was ultrasonically dissolved in 40mL of acetone, 40mL of xylene, and 20mL of tert-butyl acetate in a mixed solvent, Prepare polyurethane glue;

[0111] (3) Weigh 1.1g of hydrophilic fumed silica with a particle size of 7-40nm and 0.9g of silica with an average particle size of 300nm, stir and ultrasonically disperse them in 100mL of n-hexane, ultrasonically for 1.5 hours; then add 4g of perfluorooctyltrichlorosilane, after continuing to stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com