Aspergillus oryzae bacterial strain for producing feed compound enzyme with high yield and application of aspergillus oryzae bacterial strain

A technology of compound enzyme for feed and Aspergillus oryzae, applied in the directions of application, enzyme, hydrolase, etc., can solve the problems of complex steps and low production efficiency, and achieve the effect of easy cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

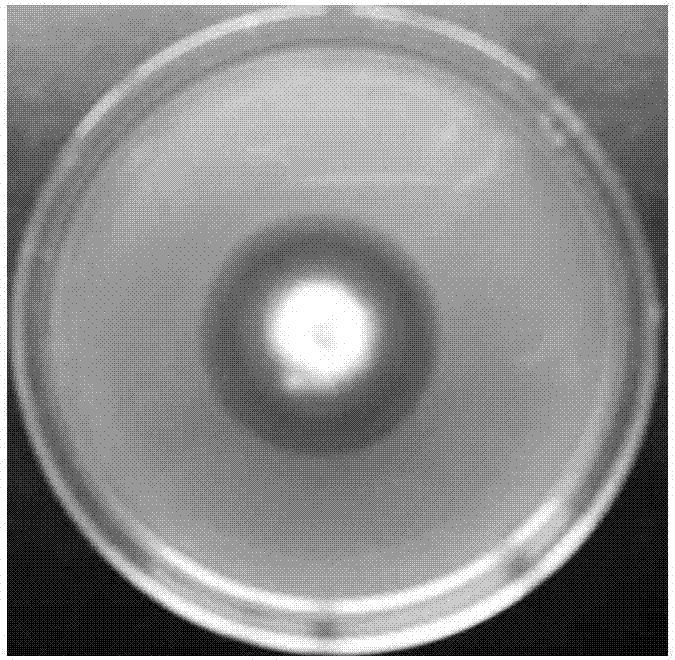

[0048] 1. Preparation of high-yield serving compound enzyme protease and inulinase strain

[0049] (1) Sampling and sample processing:

[0050] Take 20 soil samples from places rich in protein and Jerusalem artichoke, such as slaughterhouses, meat sales markets, bean product processing factories, and Jerusalem artichoke plantations in Xuzhou City, Jiangsu Province. Weigh 5g of the solid soil sample, put it into a conical flask filled with glass beads and 100mL of sterilized saline, shake it at room temperature at a speed of 180r / min for 20-30min, and make a suspension for use.

[0051] (2) Enrichment culture:

[0052] Take 2-4mL of the treated soil sample turbid liquid, add it to a 250mL Erlenmeyer flask filled with 30-60mL enrichment medium 1, and place it on a constant temperature shaker at 35-40°C and a speed of 180-200r / min Culture in medium for 5-7 days; then measure 30-50mL of enriched culture medium into a centrifuge tube under aseptic operation, centrifuge at 4000-50...

Embodiment 2

[0089] Prepare the polypeptide-rich feed additive (being applicable to the situation that the secondary seed culture liquid of required fermentation is less) with triangular flask fermentation, comprises the following steps:

[0090] Step 1, strain activation

[0091] Scrape 1 ring of Aspergillus oryzae spores from the preserved Aspergillus oryzae DJ36 strain slant, inoculate it on the activated solid seed medium of the strain, and culture it statically in a biochemical incubator at 28-32°C for 3-5 days. After the species is activated and the spores are fully mature, the culture is terminated.

[0092] Step 2, prepare the monospore suspension of Aspergillus oryzae

[0093] Wash the spores cultivated in step 1 with 0.75% sterile saline containing 0.01% v / v Tween 80, put them into a conical flask filled with 50 mL of sterile saline and sterile glass beads, and shake fully for 20 -30min. After the spores are fully dispersed, the prepared spore content is 1.0×10 8 CFU / mL of sp...

Embodiment 3

[0105] Prepare the polypeptide-rich feed additive by fermenting in a fermenter (applicable to the situation that the secondary seed culture liquid of the required fermentation is more), the difference between its preparation steps and Example 2 is that the preparation of the compound enzyme by liquid fermentation in step 4 The specific operation is:

[0106] Put 8-10L of fermentation medium in a 15L fermenter, raise the temperature of the jacket of the fermenter to 95°C, then directly pass steam into the fermentation medium, sterilize at 121°C for 20-30min, and gradually lower the temperature to 28- 32°C, take 400-1000mL of the secondary seed culture solution obtained in step 2 and inoculate it in the fermenter by flame method, the pressure of the fermenter is 0.05MPa; the initial fermentation control conditions are: temperature 28-32°C, initial pH of the fermentation medium 5. 5-6.5, sterile air ventilation ratio 1:0.6-0.8 (V / V), stirring speed 260-300r / min, keep dissolved ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com