Optically driven bilayer composite film based on graphene oxide and its preparation method and application

A double-layer composite, graphene film technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of large volume, difficulty in shrinking and integration of external equipment, and achieve fast response speed and deformation. The effect of large degree and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

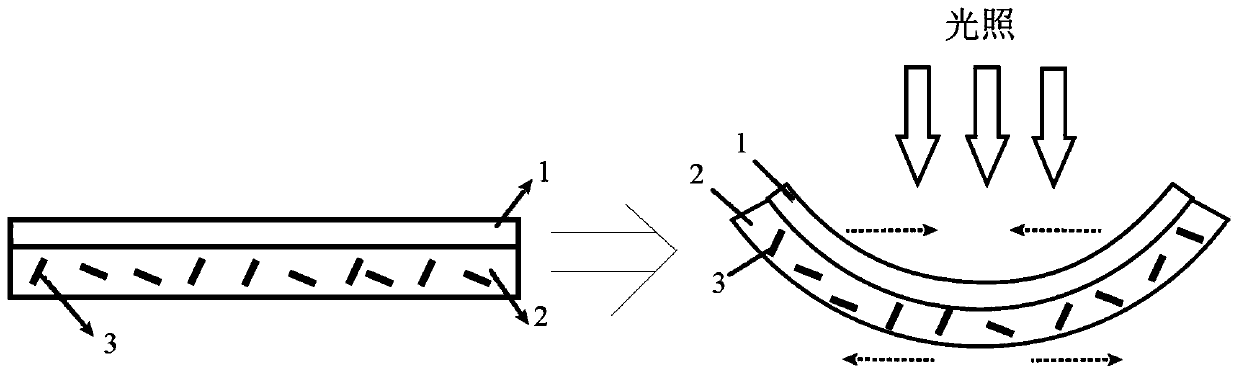

[0031] The preparation method of the graphene oxide-based light-driven double-layer composite film of the present invention comprises the following steps.

[0032] 1. Preparation of graphene oxide films with optical transparency.

[0033] The graphene oxide powder can be dispersed into solvent two to form a dispersion liquid, and the dispersion liquid is placed on the substrate and evaporated at low temperature to form a graphene oxide film with certain transparency.

[0034] In this step, the graphene oxide is a two-dimensional planar material containing various oxygen-containing functional groups on the graphene structural skeleton, and the oxygen-containing functional groups include hydroxyl, carboxyl or epoxy bonds. Solvent two includes one of water, methanol, ethanol, ethylene glycol, and isopropanol or a mixture of two or more in any proportion.

[0035] In this step, the dispersion liquid is placed on the substrate to evaporate the solvent, wherein the substrate is one...

Embodiment 1

[0047] see Figure 1 to Figure 3 , weighed 150mg of graphene oxide powder and dispersed it in 50ml of water, ultrasonically dispersed for 1h, and configured into a dispersion with a concentration of 3mg / ml. Take 3ml graphene oxide dispersion and place it to a size of 75x25cm 2 After drying at a low temperature of 50° C. on a glass substrate, a few-layer graphene oxide film 1 with certain transparency is obtained. After that, disperse 10 mL of 0.3 nM gold nanorods, that is, noble metal nanomaterials 3 (with an aspect ratio of 2), into 0.2 mL of ethanol, and stir thoroughly for 0.5 h; add the solution to 3 g of PDMS precursor, and ultrasonically stir 1h, heated at 40°C for 10 minutes to evaporate ethanol, then added 0.3g of PDMS cross-linking agent, and continued ultrasonic stirring for 0.5h to obtain a viscous mixture of PDMS and gold nanorods, that is, a mixture of PDMS and noble metal nanomaterials . Fix the glass substrate with the graphene oxide film 1 attached on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com