Temperature-sensitive type amino resin, manufacturing method and application of amino resin

A temperature-sensitive, amino resin technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of long regeneration time, expensive polymer chelating resin, etc., and achieve cost Low, easy to quickly regenerate and recycle, the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Step 1, the temperature-sensitive amino resin that the molar ratio of synthesizing formaldehyde and urea is 1.0.

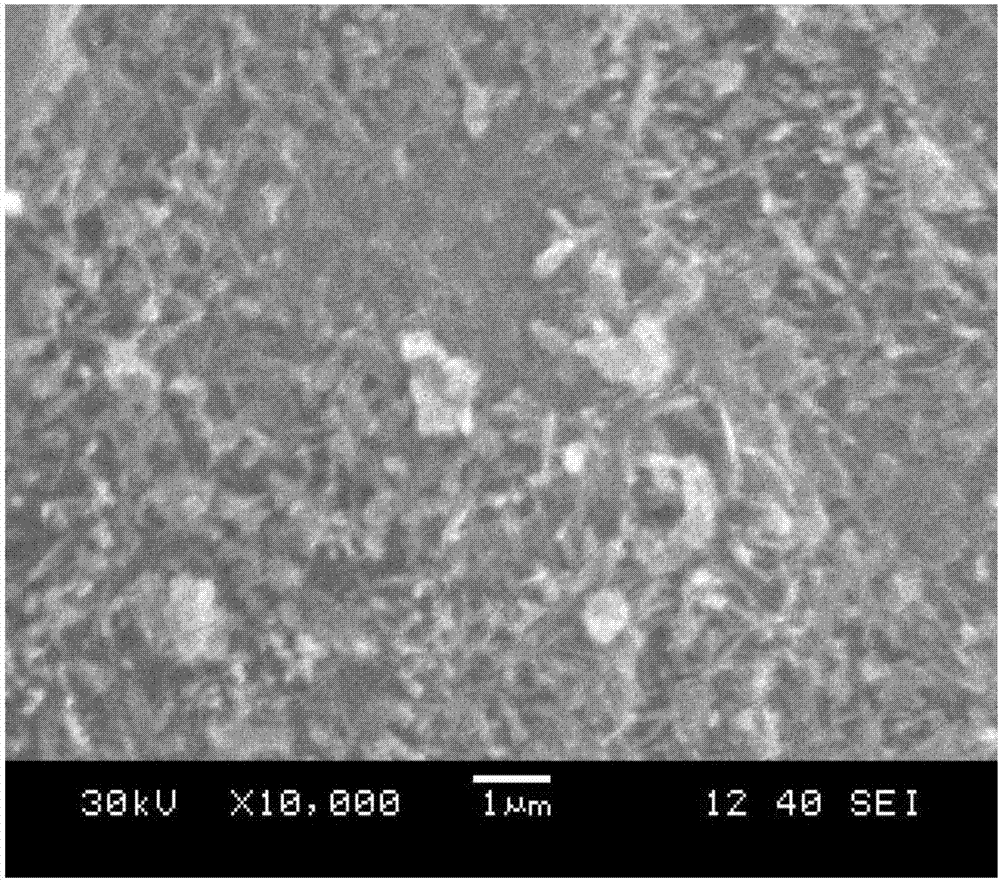

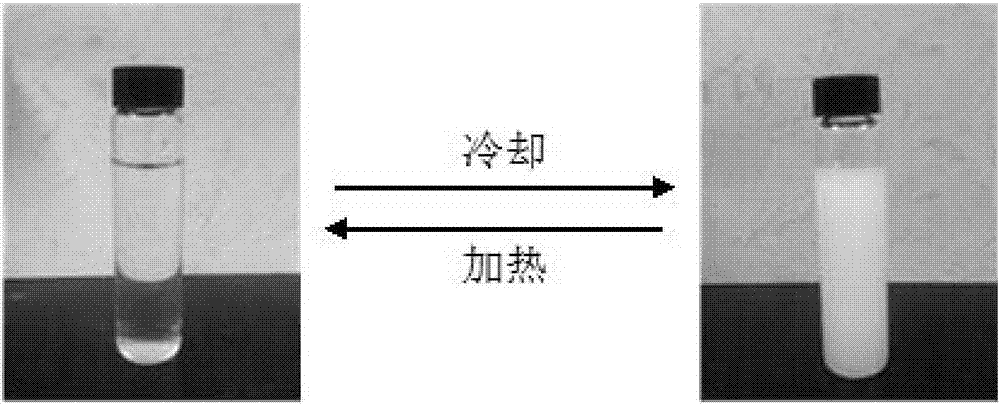

[0057] Add 406.3g of 37% formaldehyde solution into a 1L four-neck flask, add the first batch of urea 103.9g, and stir at 25°C. After the urea is completely dissolved, adjust the pH value to 7.5 with a small amount of ammonia water, mix and stir, and heat up to After 95°C, react for one hour; adjust the pH value to 6.0 with a small amount of ammonium chloride, and continue the reaction for 1 hour; cool down to 85°C, add the second batch of urea 196.4g, adjust the pH to 4.0, and react for 50 minutes; cool down to 40°C, react end to obtain a temperature-sensitive amino resin, with such figure 1 The microstructure shown and figure 2 temperature sensitivity characteristics shown.

[0058] Step 2, using temperature-sensitive amino resin as an adsorbent to adsorb cerium ions in water.

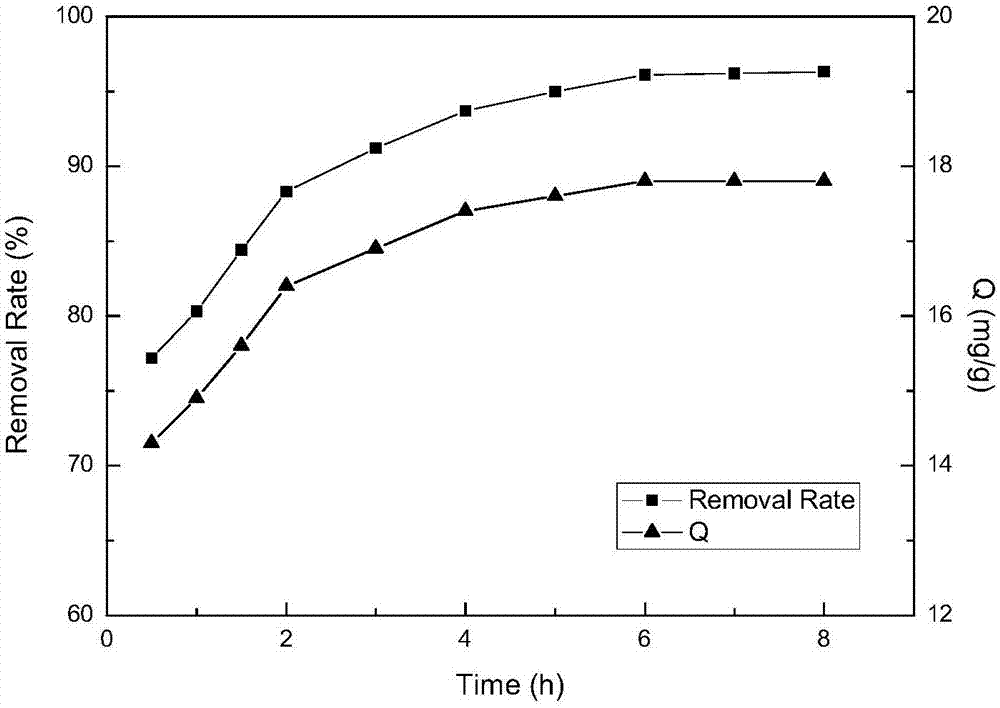

[0059] Adsorption was carried out on a constant temperature shaker. The ...

Embodiment 2

[0061] Step 1, the temperature-sensitive amino resin that the molar ratio of synthesizing formaldehyde and urea is 1.0.

[0062] Add 406.3g of 37% formaldehyde solution into a 1L four-neck flask, add the first batch of urea 106.9g, and stir at 25°C. After the urea is completely dissolved, adjust the pH value to 8.0 with a small amount of ammonia water, mix and stir, and heat up to After 90°C, react for one hour; adjust the pH value to 6.5 with a small amount of ammonium chloride, and continue the reaction for 1 hour; cool down to 85°C, add the second batch of urea 193.4g, adjust the pH to 4.5, and react for 30 minutes; cool down to 40°C, react The end result is a temperature-sensitive amino resin.

[0063] Step 2, using temperature-sensitive amino resin as an adsorbent to adsorb cerium ions in water.

[0064] Adsorption was carried out on a constant temperature shaker. The initial concentration of cerium ions is 100mg / L, the pH value of the solution is 4.5, and the adsorptio...

Embodiment 3

[0066] Step 1, the temperature-sensitive amino resin that the molar ratio of synthesizing formaldehyde and urea is 1.0.

[0067] Add 406.3g of 37% formaldehyde solution into a 1L four-necked flask, add the first batch of urea 100.3g, and stir at 25°C. After the urea is completely dissolved, adjust the pH value to 7.5 with a small amount of ammonia water, mix and stir, and heat up to After 98°C, react for one hour; adjust the pH value to 6.0 with a small amount of ammonium chloride, and continue the reaction for 1 hour; cool down to 85°C, add the second batch of urea 200g, adjust the pH to 4.0, and react for 70 minutes; cool down to 40°C, and the reaction ends A temperature-sensitive amino resin is obtained.

[0068] Step 2, using temperature-sensitive amino resin as an adsorbent to adsorb cerium ions in water.

[0069] Adsorption was carried out on a constant temperature shaker. The initial concentration of cerium ions is 100mg / L, the pH value of the solution is 4.5, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com