Preparation method of basic manganese chloride

A manganese chloride, basic technology, applied in the field of animal feed additives, can solve the problems of unstable chemical properties, not easy to absorb, low bioavailability, etc., to achieve both economy and environmental protection, uniform particles, good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

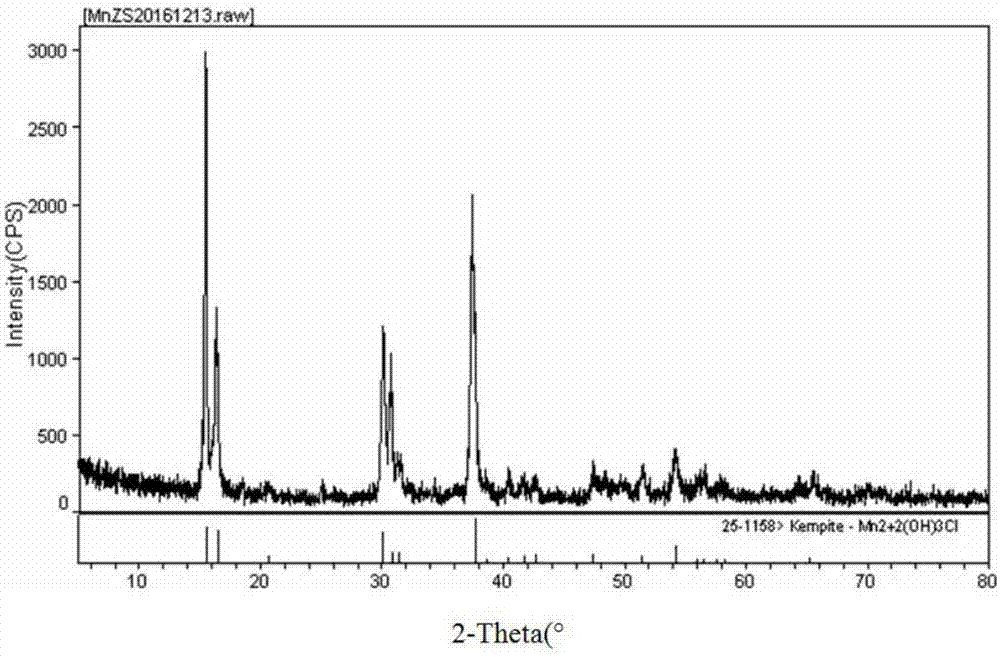

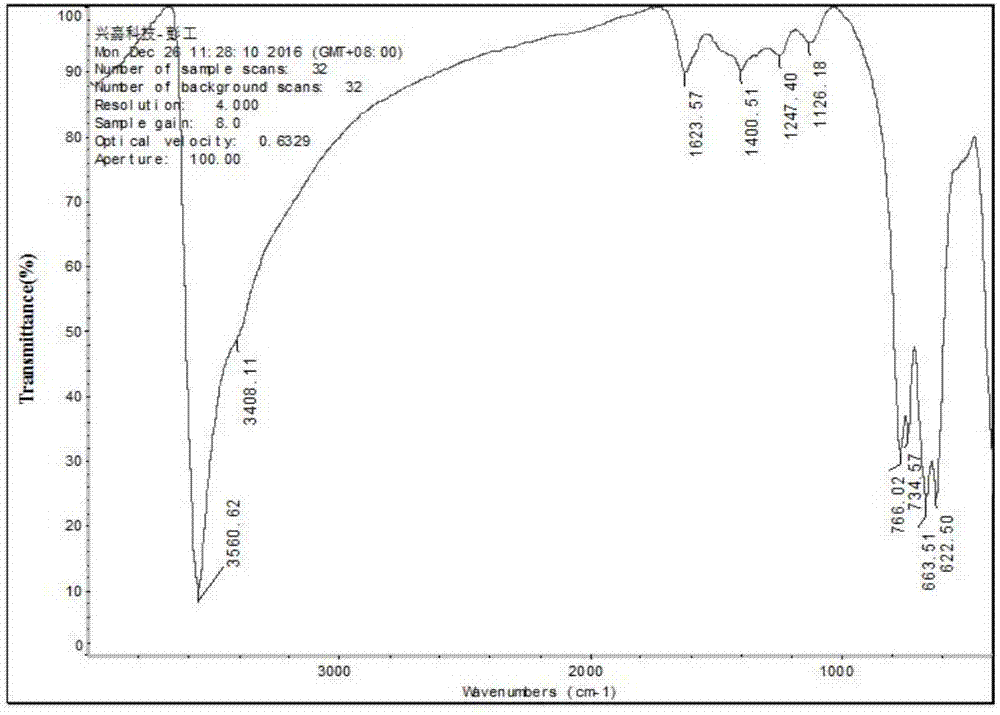

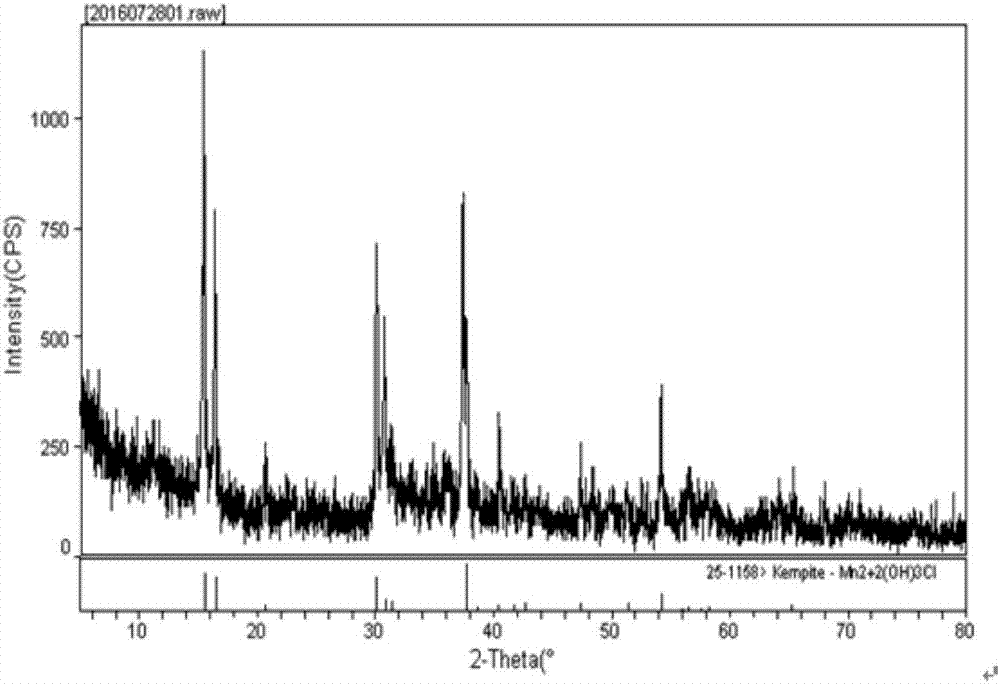

Image

Examples

Embodiment 1

[0037] A preparation method for basic manganese chloride, comprising the following steps:

[0038] 2m to the sealed 3 Add 856Kg mass fraction in the ceramic reactor and be 15% ammonium chloride solution, then add 1.1Kg sodium lauryl sulfate, finally slowly add 148Kg of manganese oxide with a purity of 96% under stirring, heat the reaction solution with hot steam, After the reaction temperature reaches 80°C, react at a constant temperature for 6 hours. After the reaction is completed, discharge the material and press filter, wash 3 times with a mixed solution with a volume ratio of ethanol and water of 10:1, and then flash dry to obtain 192.4Kg of basic manganese chloride. , The yield is 95% based on manganese.

[0039]In this embodiment, the experimental devices mainly include a ceramic reaction kettle, a feeding bin and an exhaust gas absorption device. Among them, there is a material pipeline below the feeding bin connected to the upper part of the ceramic reaction kettle....

Embodiment 2

[0044] A preparation method for basic manganese chloride, comprising the following steps:

[0045] 2m to the sealed 3 Add 1162Kg mass fraction in the ceramic reactor and be 23% ammonium chloride solution, then add 447g fatty alcohol sodium sulfate, finally slowly add 148Kg of manganese oxide with a purity of 96% under stirring, heat the reaction solution with hot steam, and the reaction temperature reaches After the reaction at 98°C for 4 hours at a constant temperature, after the reaction was completed, the material was discharged and pressure filtered, washed 3 times with a mixed solution of acetone and water with a volume ratio of 1:1, and then flashed and dried to obtain 194.5Kg of basic manganese chloride. The calculated yield was 97%.

[0046] In this embodiment, the experimental devices mainly include a ceramic reaction kettle, a feeding bin and an exhaust gas absorption device. Among them, there is a material pipeline below the feeding bin connected to the upper part...

Embodiment 3

[0051] A preparation method for basic manganese chloride, comprising the following steps:

[0052] 5m to the sealed 3 Add 1910Kg of ammonium chloride solution with a mass fraction of 28% in the ceramic reactor, then add 0.7Kg of fatty alcohol ether sodium sulfate, and finally slowly add 148Kg of manganese oxide with a purity of 96% under stirring, heat the reaction solution with hot steam, and react After the temperature reached 98°C, the reaction was carried out at a constant temperature for 3 hours. After the reaction was completed, the material was discharged and press-filtered, washed 3 times with a mixed solution with a volume ratio of ethanol and water of 2:1, and then flashed and dried to obtain 196.5Kg of basic manganese chloride. The yield is 98% based on manganese.

[0053] In this embodiment, the experimental devices mainly include a ceramic reaction kettle, a feeding bin and an exhaust gas absorption device. Among them, there is a material pipeline below the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com