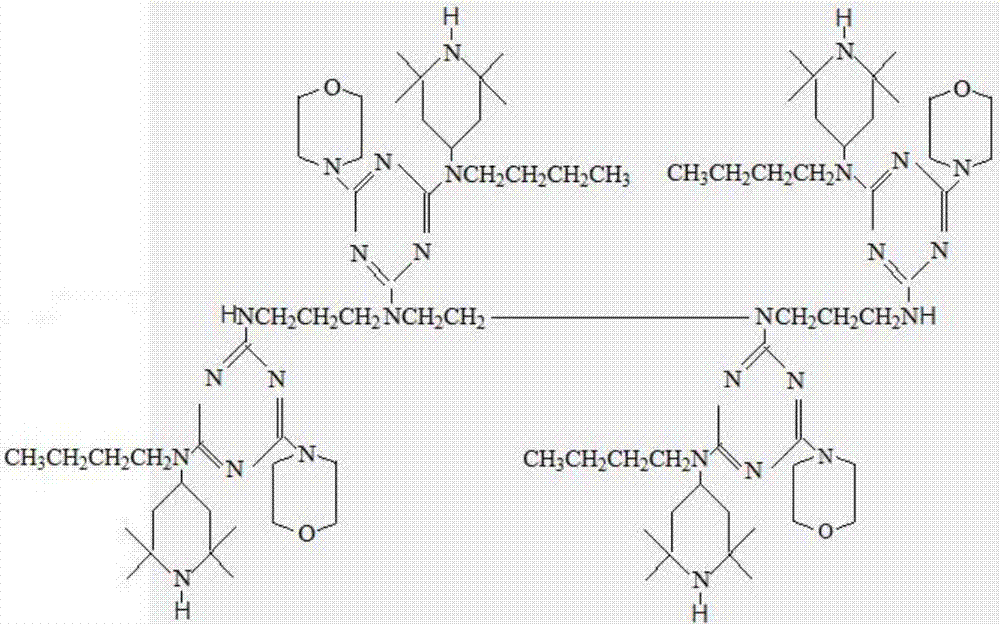

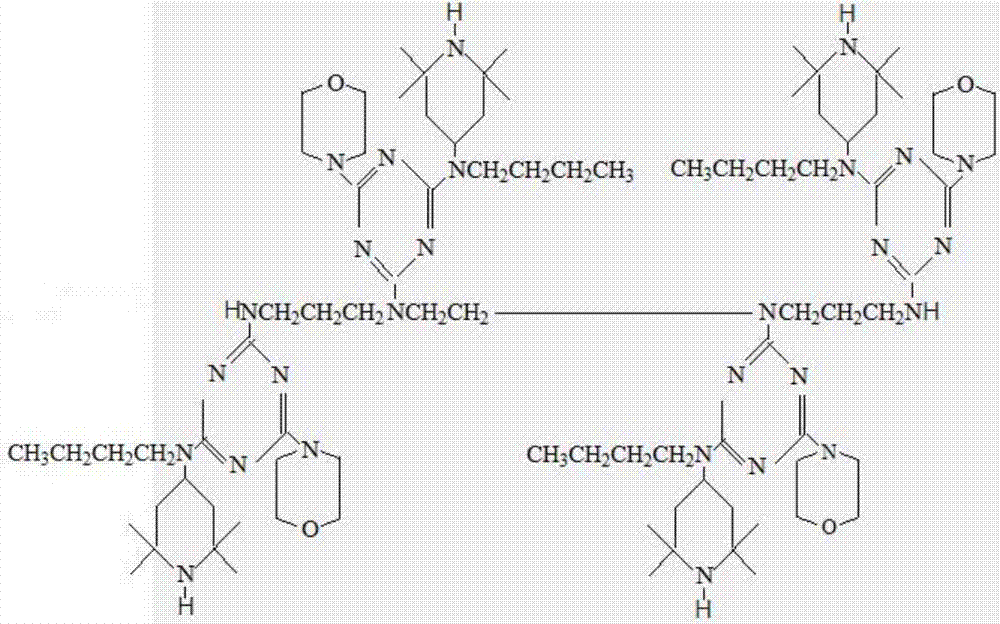

Light stabilizer and preparation method thereof

A light stabilizer and organic solvent technology, applied in the field of light stabilizer and its preparation process, can solve the problems of easy migration of hindered amine molecules, poor compatibility of industrial solvents, intolerance to pesticides, etc., and achieve superior polymer compatibility, Good compatibility, not easy to volatilize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

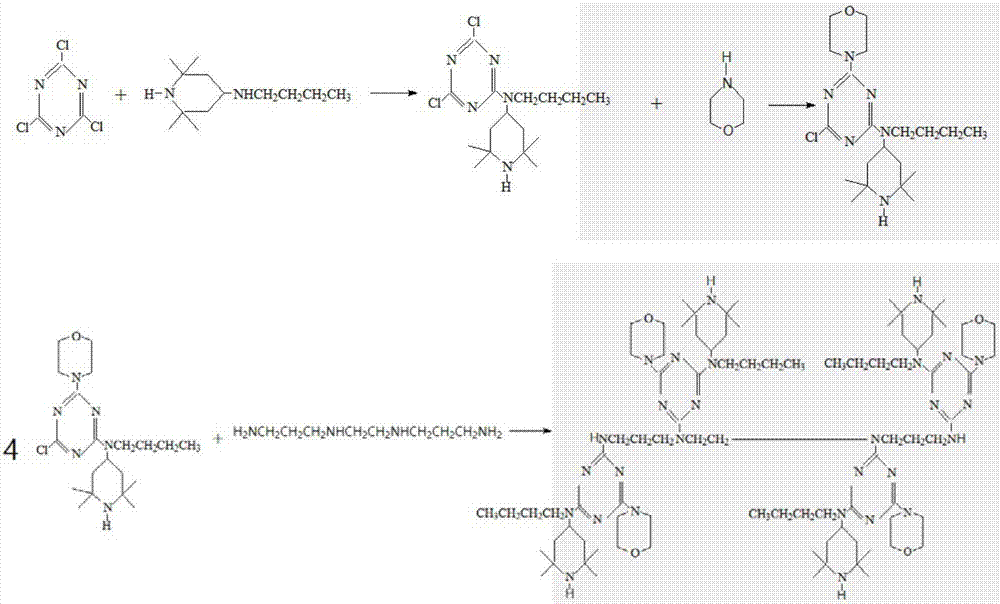

[0025] A preparation method of light stabilizer, comprising the following steps:

[0026] Add 92g of acetone solvent into a 500ml four-necked bottle, cool down to 0-5°C in an ice-water bath, add 18.45g of cyanuric chloride, and add 21.2g of N-butyl-2 dropwise under the condition of controlling the temperature at 5-10°C. 2,6,6-Tetramethyl-4-piperidinamine, the dropwise addition was completed in about 20 minutes, after the dropping, the temperature was controlled at 5-10°C for 3 hours, and the gas phase detection raw material N-butyl-2,2,6, After the reaction of 6-tetramethyl-4-piperidinamine is complete, add 8.7g of morpholine dropwise, and then add 12.3g of sodium hydroxide solution with a mass fraction of 30% dropwise, raise the temperature to 60°C for 3 hours, and the reaction is complete After cooling, washing with water, filtering and drying to obtain 37.8g solid intermediate, the yield is 92.19%;

[0027] In the autoclave with a volume of 500ml, add 55g of acetone solven...

Embodiment 2

[0030] A preparation method of light stabilizer, comprising the following steps:

[0031] Add 110g of xylene solvent into a 500ml four-necked bottle, cool down to 0-5°C in an ice-water bath, add 18.45g of cyanuric chloride, and dropwise add 21.5g of N-butyl-2 under the condition of controlling the temperature at 5-10°C , 2,6,6-Tetramethyl-4-piperidinamine, the dropwise addition was completed in about 20 minutes, and the temperature was controlled at 5-10°C for 4 hours after the dropping, and the raw material N-butyl-2,2,6 was detected by gas phase , the reaction of 6-tetramethyl-4-piperidinamine is complete, and then 8.9g of morpholine is added dropwise, and then 13.4g of sodium hydroxide solution with a mass fraction of 30% is added dropwise, and the temperature is raised at 65°C for 4h, and the reaction After completion, the temperature was lowered, washed with water, filtered and dried to obtain 37.0 g of solid intermediate with a yield of 90.24%;

[0032] In the autoclave...

Embodiment 3

[0035] A preparation method of light stabilizer, comprising the following steps:

[0036] Add 130g of DMF solvent into a 500ml four-necked bottle, cool down to 0-5°C in an ice-water bath, add 18.45g of cyanuric chloride, and add 21.2g of N-butyl-2 dropwise under the condition of controlling the temperature at 5-10°C, 2,6,6-Tetramethyl-4-piperidinamine, the dropwise addition was completed in about 20 minutes, and the temperature was controlled at 5-10°C to react for 5h after the dropping, and the gas phase detection raw material N-butyl-2,2,6, After the reaction of 6-tetramethyl-4-piperidinamine is complete, add 8.7g of morpholine dropwise, then add 13.4g of sodium hydroxide solution with a mass fraction of 30% dropwise, heat up to 70°C for 5 hours, and the reaction is complete After cooling, washing with water, filtering and drying to obtain 37.6g solid intermediate, the yield is 91.71%;

[0037] In the autoclave with a volume of 500ml, add 86g of DMF solvent, add 37.6g of in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com