Heat-insulating building material

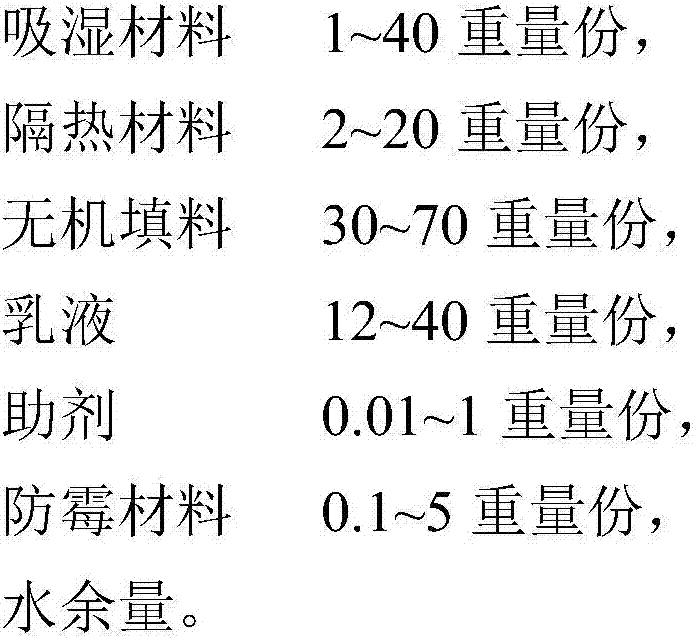

A building material, thermal insulation technology, used in biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problems of water vapor fogging, human health hazards, mold growth, etc., to inhibit mold effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

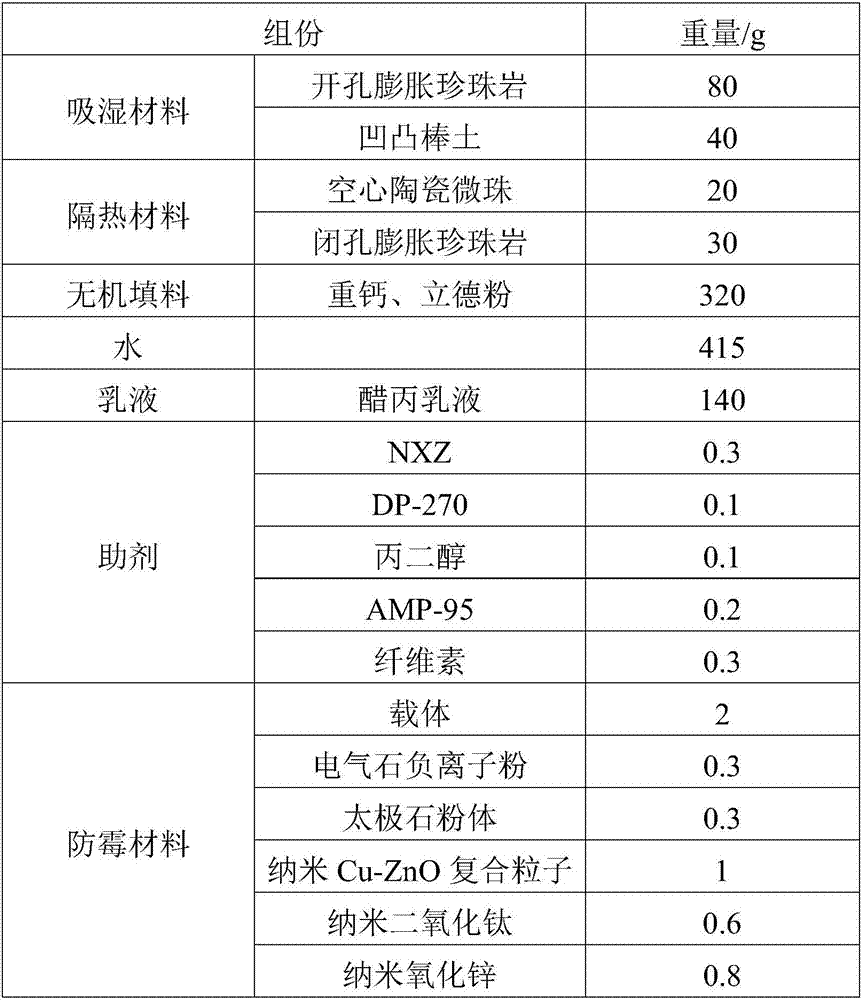

Embodiment 1

[0034] Embodiment 1, prepare the building material according to the ratio in the table below.

[0035]

[0036] Use this building material to make a coating, and perform functional tests respectively:

[0037] 1. Hygroscopicity: Make a coating sample with a thickness of 2mm-3mm. After the prepared sample was dried naturally for 24 hours, it was dried in a drying oven at 80°C for 5 hours. Then place it in a humidity-conditioning box to carry out a moisture absorption test, and the test conditions are a temperature of 25° C. and a relative humidity of 85%. After 48 hours, take it out and weigh it. Through the calculation of the mass before and after the test, it is concluded that the moisture absorption of the sample reaches 300g / m 2 , indicating that the test coating has moisture absorption function; put the moisture-absorbing sample into a humidity-conditioning box with a temperature of 25°C and a relative humidity of 35%, take it out and weigh it after 48 hours, and obta...

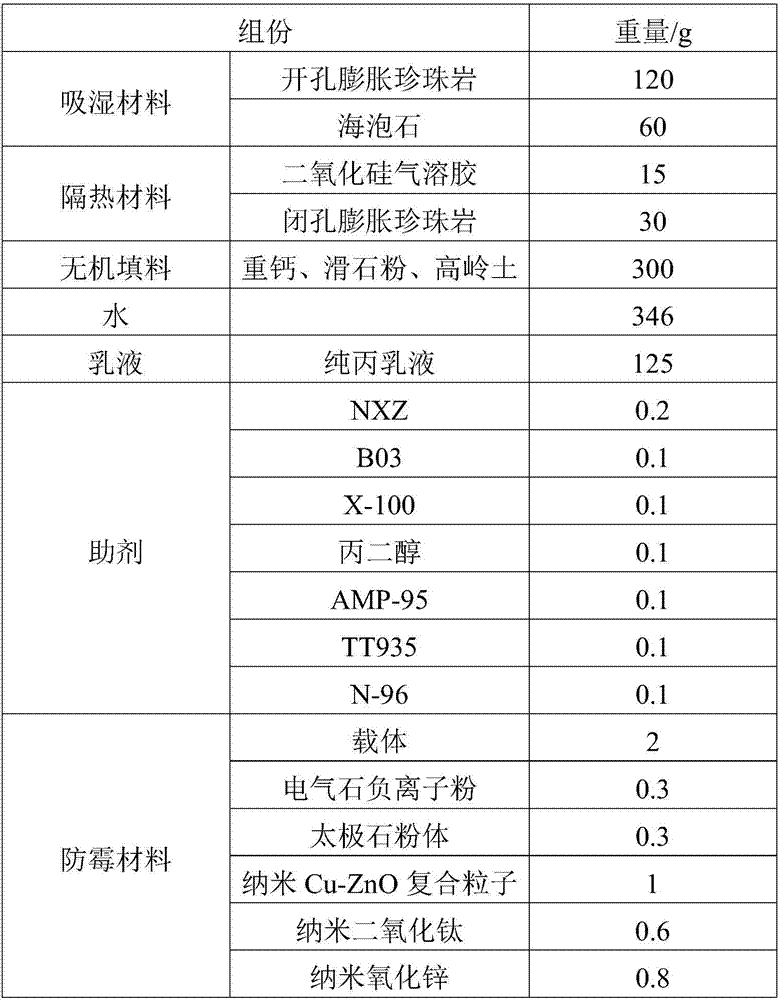

Embodiment 2

[0040] Embodiment 2, prepare the building material according to the ratio in the table below.

[0041]

[0042] The same method used in Example 1 was used for functional testing, and the results showed that the coating made of this coating was tested in a humidity control box. Under the conditions of a temperature of 25°C and a relative humidity of 85%, the moisture absorption reached 320g / m 2 ;Under the conditions of temperature 25℃ and relative humidity 35%, the moisture release can reach 260g / m 2 , has good moisture absorption and desorption functions; the coating’s killing rate against six comprehensive molds of Candida albicans and Aspergillus niger has reached level 0; the killing rate against Staphylococcus aureus and Escherichia coli are respectively: 99.9% and 99.9%; the thermal conductivity of the coating measured by the coating thermal conductivity tester is 0.035W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com