Environment-friendly adhesive for metal hoses and rubber hoses as well as preparation method of adhesive

A metal hose and adhesive technology, applied in the field of material chemistry, can solve the problems of affecting the viscosity of the adhesive, affecting the modification effect of the adhesive, etc., and achieve the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

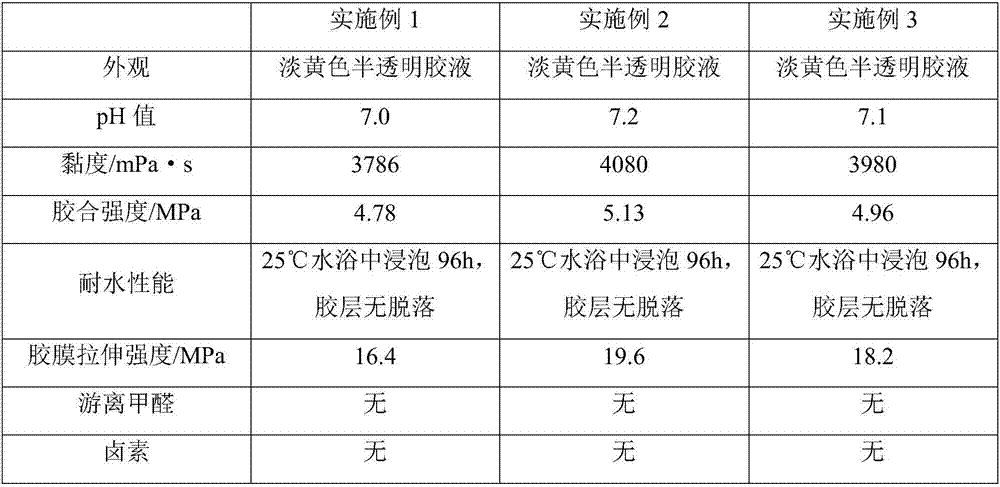

Examples

Embodiment 1

[0025] An environmentally friendly adhesive for metal hoses and rubber hoses, made of the following components in proportion by weight: 17 parts of chlorosulfonated polymer, 11 parts of polyvinyl alcohol, 8 parts of phenolic resin, 11 parts of isocyanate, 12 parts of montmorillonite, 7 parts of titanium dioxide, 8 parts of copper oxide, 7 parts of iron sulfate, 11 parts of borax.

[0026] A method for preparing an environment-friendly metal hose and rubber hose adhesive, comprising the following steps:

[0027] (1) Preparation of adhesive matrix: mix chlorosulfonated polymer and phenolic resin, add tetrahydrofuran to it, the total mass of the mixture: the volume of tetrahydrofuran is 1:2, stir and mix well, heat to 85°C, and stir while heating , to obtain the adhesive matrix;

[0028] (2) Preparation of the first modifying agent: mix montmorillonite, titanium dioxide, copper oxide and ferric sulfate, grind them into powder, add sulfuric acid solution with a mass fraction of 8...

Embodiment 2

[0034] An environment-friendly adhesive for metal hoses and rubber hoses, made of the following components in parts by weight: 27 parts of chlorosulfonated polymer, 22 parts of polyvinyl alcohol, 16 parts of phenolic resin, 21 parts of isocyanate, 28 parts of montmorillonite, 13 parts of titanium dioxide, 11 parts of copper oxide, 8 parts of iron sulfate, 16 parts of borax.

[0035] A method for preparing an environment-friendly metal hose and rubber hose adhesive, comprising the following steps:

[0036] (1) Preparation of adhesive matrix: mix chlorosulfonated polymer and phenolic resin, add tetrahydrofuran to it, the total mass of the mixture: the volume of tetrahydrofuran is 1:4, stir and mix well, heat to 92 ° C, and stir while heating , to obtain the adhesive matrix;

[0037] (2) Preparation of the first modifying agent: mix montmorillonite, titanium dioxide, copper oxide and ferric sulfate and grind them into powder, add sulfuric acid solution with a mass fraction of 12...

Embodiment 3

[0043]An environment-friendly adhesive for metal hoses and rubber hoses, made of the following components in parts by weight: 34 parts of chlorosulfonated polymer, 30 parts of polyvinyl alcohol, 22 parts of phenolic resin, 27 parts of isocyanate, 38 parts of montmorillonite, 16 parts of titanium dioxide, 14 parts of copper oxide, 12 parts of iron sulfate, 20 parts of borax.

[0044] A method for preparing an environment-friendly metal hose and rubber hose adhesive, comprising the following steps:

[0045] (1) Preparation of adhesive matrix: mix chlorosulfonated polymer and phenolic resin, add tetrahydrofuran to it, the total mass of the mixture: the volume of tetrahydrofuran is 1:5, stir and mix, heat to 107 ° C, and stir while heating , to obtain the adhesive matrix;

[0046] (2) Preparation of the first modifying agent: after mixing montmorillonite, titanium dioxide, copper oxide and ferric sulfate, grind them into powder, add sulfuric acid solution with a mass fraction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com