Method for improving thermal conductivity of gallium oxide material

A technology of gallium oxide and two-dimensional materials, which is applied in the field of improving the thermal conductivity of gallium oxide materials, can solve the problems of high thermal conductivity, no thermal conductivity, low carrier mobility, etc., to improve thermal conductivity and facilitate promotion, high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

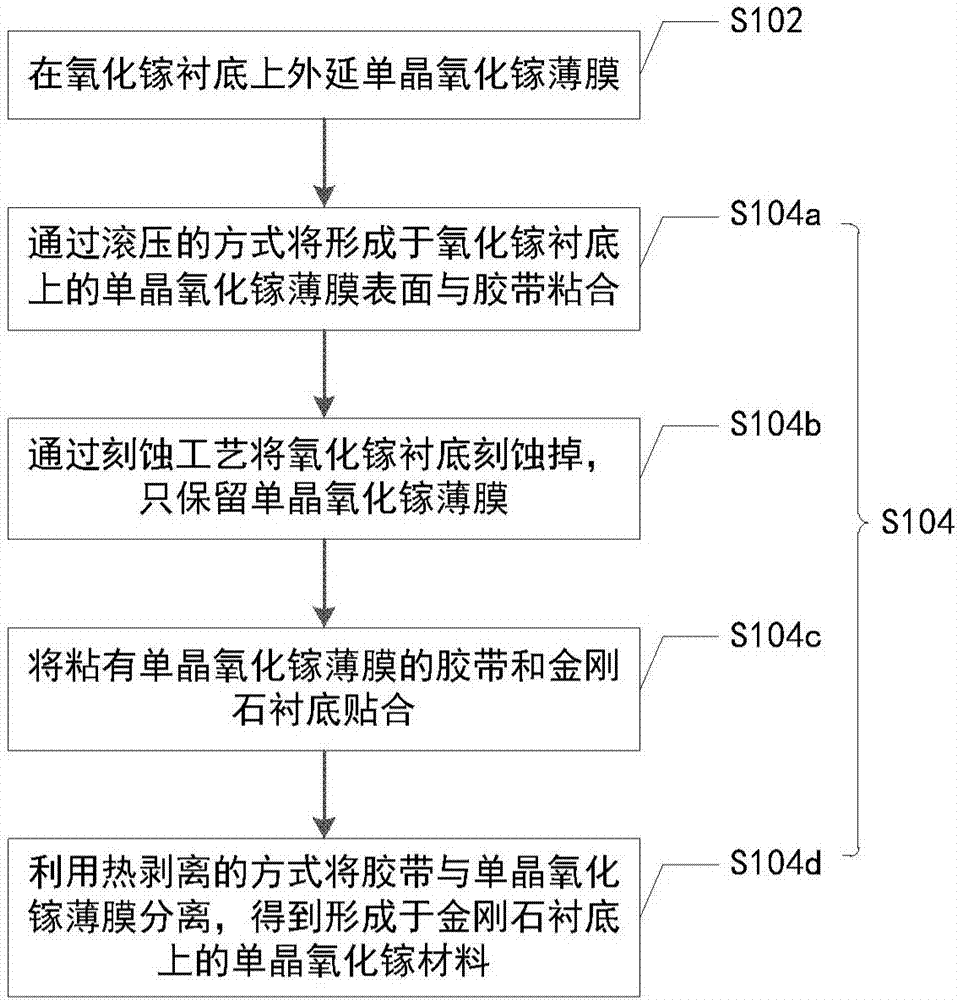

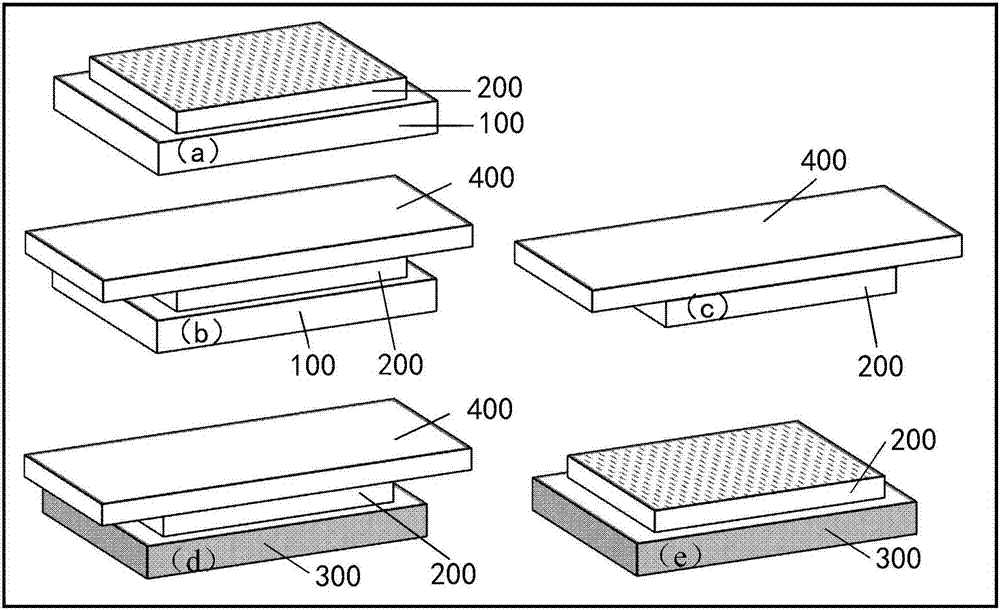

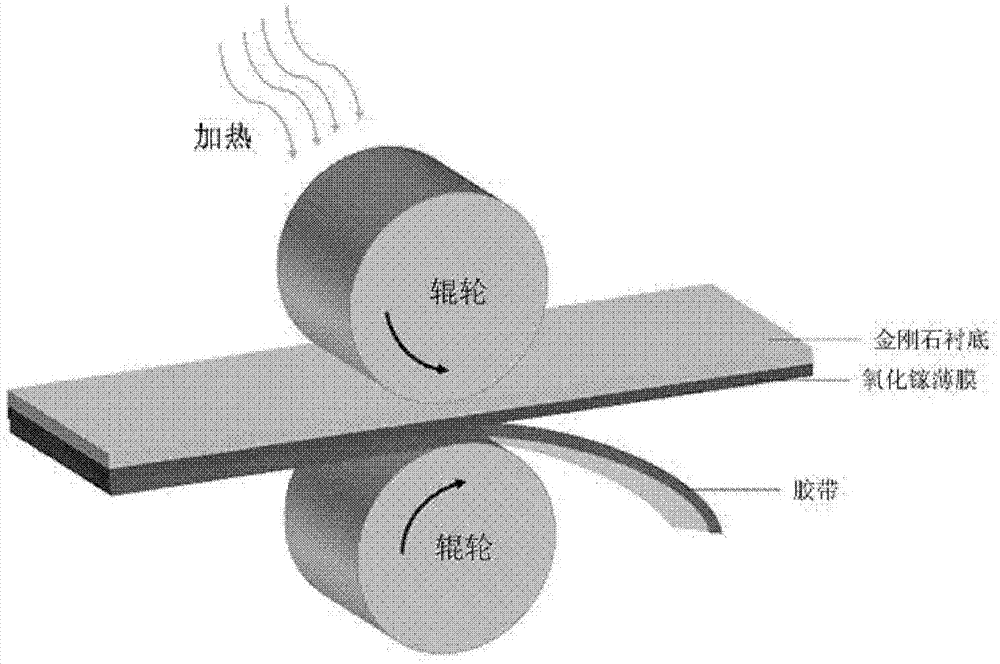

[0025] The invention provides a method for improving the thermal conductivity of gallium oxide materials, using an etching process combined with a two-dimensional material transfer method to transfer a single crystal gallium oxide film to a substrate with a thermal conductivity greater than 200W / m·K and compatible with semiconductors In terms of materials, a single crystal gallium oxide material formed on the above substrate is obtained, which effectively improves the thermal conductivity of the gallium oxide material. The present invention aims at improving the thermal conductivity of gallium oxide, and at the same time facilitates its use in the field of semiconductor device production, ensuring that gallium oxide materials are used in semiconductor devices, so the availability of gallium oxide materials must be ensured on the basis of improving thermal conductivity , so as to promote its application promotion.

[0026] In order to make the object, technical solution and adv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com