Method for dyeing high weight paper product and application thereof

A dyeing method and technology for paper products, applied in the field of papermaking, can solve the problems that the product brightness and color saturation cannot meet the customer's requirements, the light scattering coefficient on the surface of the paper is small, and it is difficult to obtain ideal effects, etc. Strong covering power and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

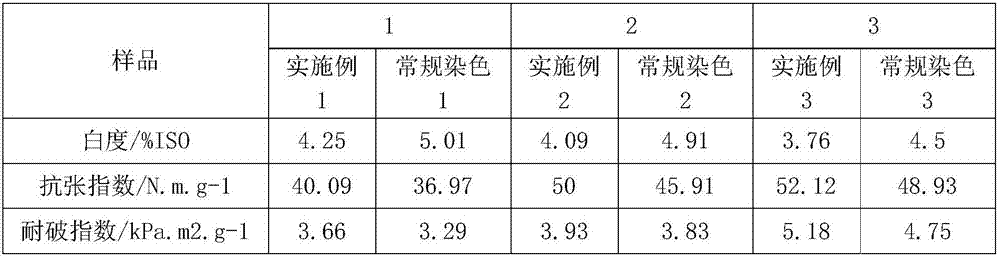

Examples

preparation example Construction

[0028] (2) Preparation of dispersion: Take 60mL of deionized water in a 100mL beaker, add 0.78g of polyacrylate dispersant and 0.72g of propanol, stir with a magnetic stirrer at a speed of 700r / min to completely disperse, and then Add 6g of spare carbon black in step (1), continue to stir and mix evenly to obtain a dispersion.

[0029] (3) Add the above-mentioned dispersion into a ball mill jar, and grind for 12 hours with a planetary ball mill to obtain a color paste.

Embodiment 1

[0031] (1) Take an appropriate amount of hardwood pulp board, bamboo pulp board and bagasse pulp board, soak for more than 4 hours, shred, decompose for 3000r, squeeze the pulp, and measure the water content of the three pulp samples after 24 hours of equilibrium. Take the pulp sample equivalent to 30g of dry pulp in a 1000mL beaker according to the dry mass percentage of hardwood pulp:bamboo pulp:bagasse pulp: 30%:50%:20%.

[0032] (2) Take 1% spare color paste relative to the dry pulp mass in a beaker, dilute and disperse for future use.

[0033] (3) Add the dispersed pigment into the slurry, dilute the mixture to a concentration of 10% (relative to the absolute dry slurry sample), stir and mix evenly. Put the mixture into a PFI mill and refine it to a degree of freeness of 25°SR.

[0034] (4) Take the equivalent of 250g / m 2 Put the ground slurry required for quantitative paper into a 2000mL beaker, add 800mL of warm water at about 60°C, and dissolve it. Place the beaker ...

Embodiment 2

[0036] (1) Take an appropriate amount of hardwood pulp board, bamboo pulp board and bagasse pulp board, soak for more than 4 hours, shred, decompose for 3000r, squeeze the pulp, and measure the water content of the three pulp samples after 24 hours of equilibrium. Take the pulp sample equivalent to 30g dry pulp in a 1000mL beaker according to the dry mass percentage of hardwood pulp:bamboo pulp:bagasse pulp: 40%:40%:20%.

[0037] (2) Take 2% spare color paste relative to the dry pulp mass in a beaker, dilute, disperse and set aside.

[0038] (3) Add the dispersed pigment into the slurry, dilute the mixture to a concentration of 10% (relative to the absolute dry slurry sample), stir and mix evenly. Put the mixture into a PFI mill and refine it to a degree of freeness of 30°SR.

[0039] (4) Take the equivalent of 300g / m 2 Put the ground slurry required for quantitative paper into a 2000mL beaker, add 800mL of warm water at about 60°C, and dissolve it. Place the beaker on a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com