Porous carbon nano fiber material for adsorbing carbon dioxide and preparation method thereof

A carbon dioxide and nanofiber technology, applied in the field of nanomaterials and environmental governance, can solve the problems of less micropore and ultramicropore content, small carbon dioxide adsorption capacity, and low specific surface area, and achieve fast adsorption kinetics and mild desorption conditions , the effect of ultra-high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

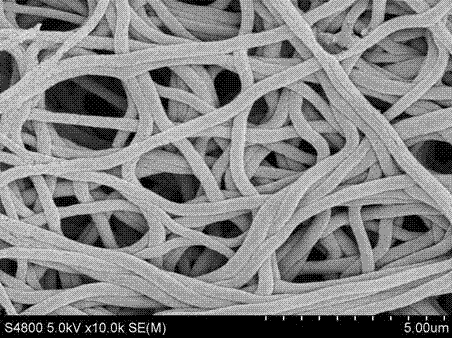

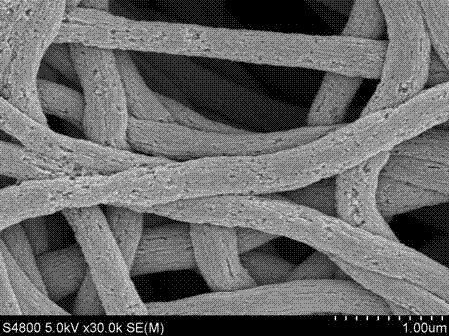

[0031] Porous carbon nanofiber material for carbon dioxide prepared from PAN and PMMA.

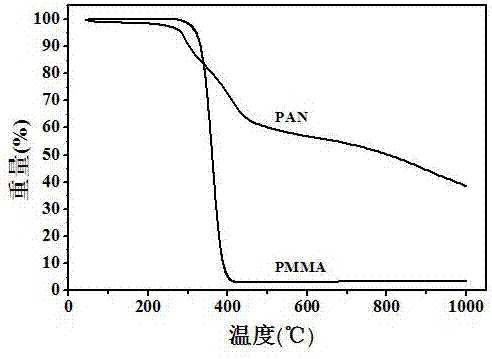

[0032] (1) Weigh ~20mg of PAN and PMMA polymer powders respectively, put them into crucibles respectively, place them in a thermogravimetric analyzer, and feed N at a flow rate of 60ml / min 2 The gas is heated to 1000°C at a heating rate of 5°C / min, and the thermogravimetric analyzer automatically records the weight loss of the two polymers. Its thermogravimetric curve, such as figure 1 shown; therefore, PAN as a carbon precursor, PMMA as an organic pore former.

[0033] (2) Weigh PAN and PMMA with a mass ratio of 1:1 and add them to DMF. Stir continuously at room temperature until the polymer is completely dissolved to form a uniform and transparent solution. The mass fraction of the spinning solution is 15%.

[0034] (3) Transfer the spinning solution prepared in step (2) into the syringe and connect it to the autosampler, connect the needle to a high-voltage power supply for electrospi...

Embodiment 2

[0040] Porous carbon nanofiber material for carbon dioxide prepared from PAN and PMMA.

[0041] (1) Weigh PAN and PMMA with a mass ratio of 1:1 and add them to DMF. At room temperature, stir continuously until the polymer is completely dissolved to form a uniform and transparent solution. The mass fraction of the spinning solution is 15%.

[0042] (2) Transfer the spinning liquid prepared in step (1) into the syringe and connect it to the autosampler, connect the needle to a high-voltage power supply for electrospinning, and use the receiving device to receive PAN / PMMA composite electrospinning Nanofiber membrane; the flow rate is 1ml / min, the spinning voltage is 17kv, and the distance between the needle and the receiver is 15cm.

[0043] (3) The electrospun composite nanofiber membrane obtained in step (2) was placed in a vacuum drying oven, and dried in vacuum at 90° C. for 12 hours to remove residual organic solvents.

[0044] (4) Place the nanofiber membrane dried in step...

Embodiment 3

[0048] Porous carbon nanofiber material for carbon dioxide prepared from PAN and PMMA.

[0049] (1) Weigh PAN and PMMA with a mass ratio of 1:1 and add them to DMF. At room temperature, stir continuously until the polymer is completely dissolved to form a uniform and transparent solution. The mass fraction of the spinning solution is 15%.

[0050] (2) Transfer the spinning liquid prepared in step (1) into the syringe and connect it to the autosampler, connect the needle to a high-voltage power supply for electrospinning, and use the receiving device to receive PAN / PMMA composite electrospinning Nanofiber membrane; the flow rate is 1ml / min, the spinning voltage is 17kv, and the distance between the needle and the receiver is 15cm.

[0051] (3) The electrospun composite nanofiber membrane obtained in step (2) was placed in a vacuum drying oven, and dried in vacuum at 90° C. for 12 hours to remove residual organic solvents.

[0052] (4) Place the nanofiber membrane dried in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com