Enhanced nano-composite forward osmosis membrane as well as preparation method and application thereof

A nano-composite, forward osmosis membrane technology, used in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve problems such as unsatisfactory proton transmission efficiency, transmission efficiency does not reach the limit, etc., achieve excellent ion exchange capacity, high Effects of porosity and ultra-high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

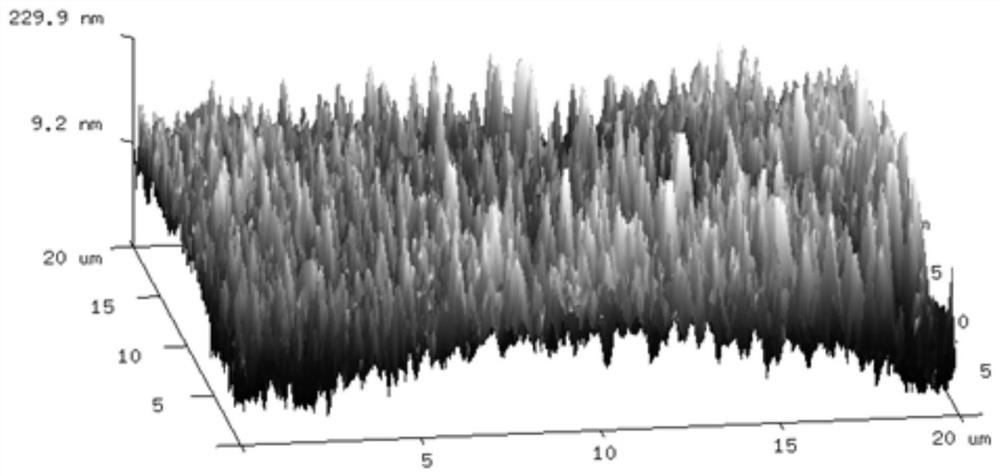

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare an enhanced nanocomposite forward osmosis membrane, the specific preparation method is as follows:

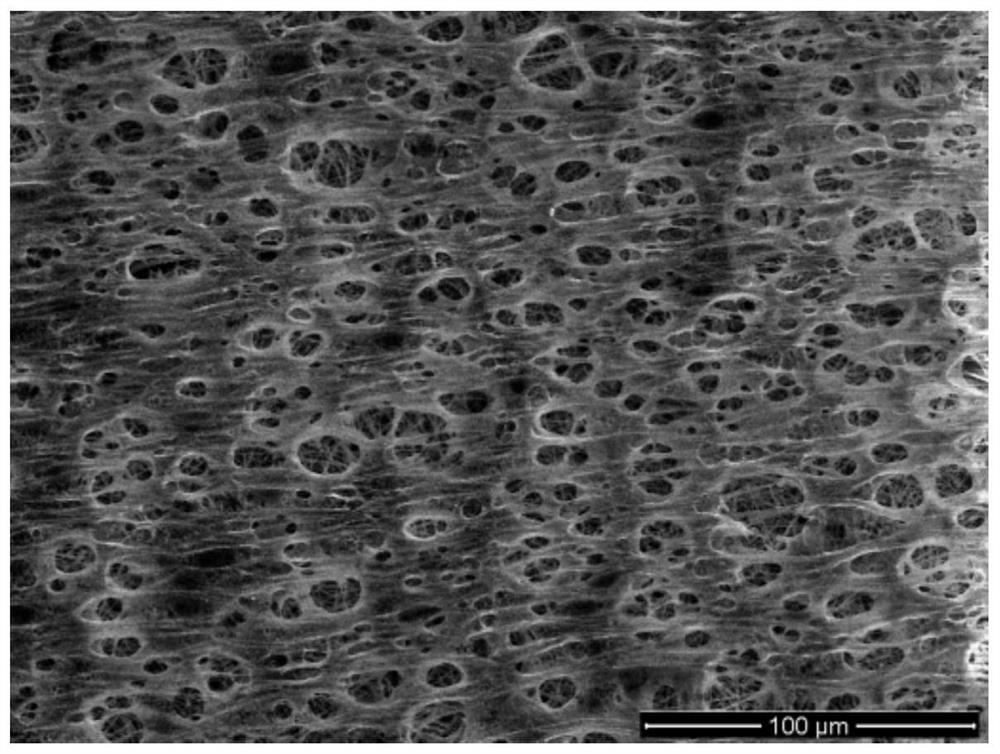

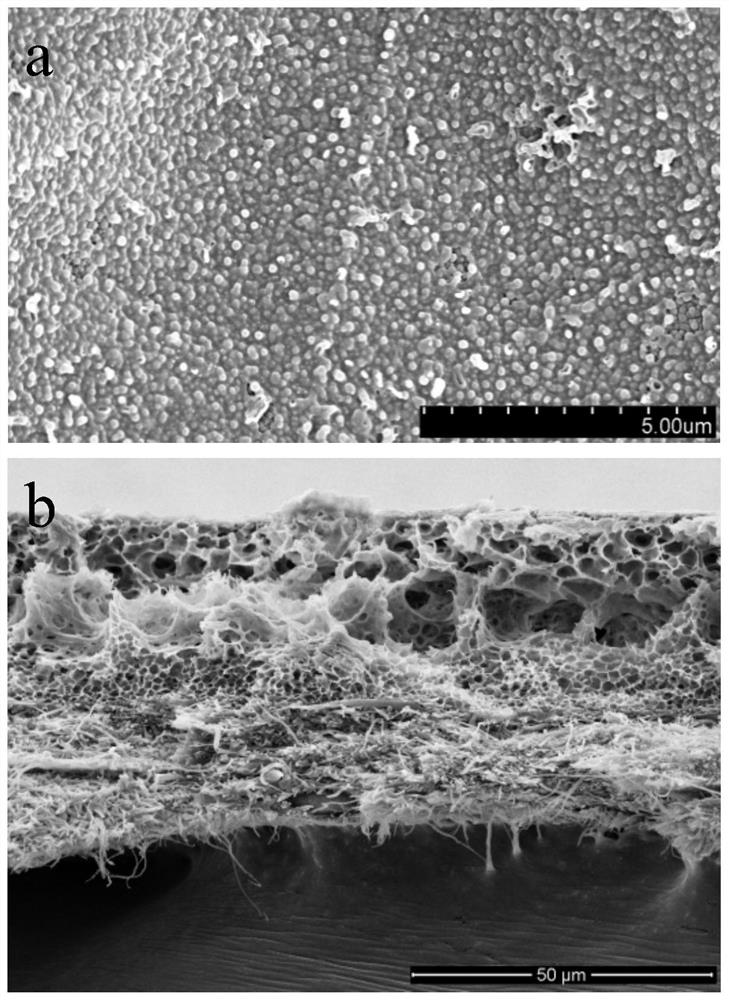

[0044] 1. Preparation of enhanced supporting base membrane: Add polysulfone particles into N,N-dimethylformamide (DMF) solvent according to the requirement of mass concentration of 5wt%, heat and stir for 12 hours to prepare a uniform and stable casting solution, static Place it for defoaming for 24 hours; spread the substrate (non-woven fabric with a pore size of 0.1 μm) on a clean glass plate, then pour the above casting solution on the non-woven fabric, adjust the height of the scraper to 150 μm, and scrape the film at a constant speed. Then the glass plate was quickly immersed in the pure water coagulation bath, and after 30 minutes, the formed phase inversion basement membrane was taken out from the coagulation bath, and rinsed repeatedly with deionized water to prepare a reinforced support basement membrane, which was placed in a deionized In water for late...

Embodiment 2

[0049] Prepare an enhanced nanocomposite forward osmosis membrane, the specific preparation method is as follows:

[0050] 1. Preparation of reinforced support base membrane: Add polyethersulfone particles into N,N-dimethylacetamide (DMAc) solvent according to the requirement of mass concentration of 20wt%, heat and stir for 12 hours, and prepare a uniform and stable casting solution , stand for defoaming for 24 hours; spread the base material (metal mesh with an average pore size of 60 μm) on a clean glass plate, then pour the above casting solution on the metal mesh, adjust the height of the scraper to 200 μm, scrape the film at a constant speed, and then The glass plate was quickly immersed in a pure water coagulation bath, and after 30 minutes, the formed phase inversion supporting basement membrane was removed from the coagulation bath, and rinsed repeatedly with deionized water to prepare a reinforced supporting basement membrane, which was soaked in deionized water at 4 ...

Embodiment 3

[0055] Prepare an enhanced nanocomposite forward osmosis membrane, the specific preparation method is as follows:

[0056] 1. Preparation of reinforced support base film: disperse polyacrylonitrile particles in N-methylpyrrolidone (NMP) solvent according to the requirement of mass concentration of 30wt%, heat and stir for 12 hours, prepare a uniform and stable casting solution, let stand to remove Soak for 24 hours; spread the base material (a screen with a pore size of 30 μm) on a clean glass plate, then pour the above casting solution on the screen, adjust the height of the scraper to 150 μm, scrape the film at a constant speed, and then quickly immerse the glass plate In a pure water coagulation bath, after 30 minutes, the formed phase inversion basement membrane was taken out from the coagulation bath, and rinsed repeatedly with deionized water to prepare a reinforced support basement membrane, which was placed in deionized water at 4°C for use.

[0057] 2. Preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com