High intensity microporous mullite refractory aggregate and preparation method thereof

A refractory aggregate and mullite technology, applied in the field of high-strength microporous mullite refractory aggregate and its preparation, can solve the problems of low production efficiency, poor corrosion resistance, unevenness, etc. The effect of high compressive strength and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

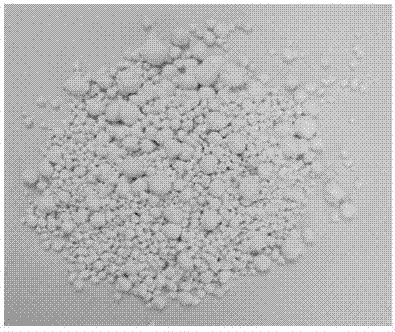

[0032] A high-strength microporous mullite refractory aggregate and a preparation method thereof. The preparation method described in this embodiment is:

[0033] (1) With 50-55wt% kaolin fine powder and 45-50wt% active α-Al 2 o 3 Micropowder is used as a raw material, and 2-2.5 wt% of dextrin, 1-1.7 wt% of metal aluminum powder and 1-1.4 wt% of carbon black are added to the raw materials, and the mixture is uniformly mixed to obtain a mixture.

[0034] (2) Mix 3-5wt% of aluminum sol, 1-1.5wt% of silica sol, 0.5-0.6wt% of spodumene and 2-3wt% of water as raw materials to prepare a slurry for later use.

[0035] (3) Put the mixture into a disc granulator, and spray the slurry while granulating to obtain granules with a particle diameter of 1-10 mm.

[0036] (4) Dry the particles naturally for 24 hours, then dry them at 100-110°C for 24-48 hours, then raise the temperature to 1200-1300°C, keep them warm for 2-4 hours, cool them naturally, and sieve them to obtain high-strengt...

Embodiment 2

[0039]A high-strength microporous mullite refractory aggregate and a preparation method thereof. The preparation method described in this embodiment is:

[0040] (1) With 55-58wt% kaolin fine powder and 42-47wt% active α-Al 2 o 3 Micropowder is used as a raw material, 2.4-2.9 wt% of dextrin, 1.6-2.3 wt% of metal aluminum powder and 1.3-1.7 wt% of carbon black are added to the raw materials, and the mixture is uniformly mixed to obtain a mixture.

[0041] (2) Mix 4-6wt% of aluminum sol, 1.3-1.8wt% of silica sol, 0.6-0.7wt% of spodumene and 3-4wt% of water to prepare a slurry for later use.

[0042] (3) Put the mixture into a disc granulator, and spray the slurry while granulating to obtain granules with a particle diameter of 1-10 mm.

[0043] (4) Dry the granules naturally for 24 hours, then dry them at 100-110°C for 24-48 hours, then raise the temperature to 1250-1350°C, keep them warm for 2-4 hours, cool naturally, and sieve to obtain high-strength microporous mullite St...

Embodiment 3

[0046] A high-strength microporous mullite refractory aggregate and a preparation method thereof. The preparation method described in this embodiment is:

[0047] (1) With 56-61wt% kaolin fine powder and 39-44wt% active α-Al 2 o 3 Micropowder is used as a raw material, and 2.8-3.3 wt% of dextrin, 2.2-2.9 wt% of metal aluminum powder and 1.6-2.0 wt% of carbon black are added to the raw materials, and the mixture is uniformly mixed to obtain a mixture.

[0048] (2) Mix 5-7wt% of aluminum sol, 1.6-2.1wt% of silica sol, 0.7-0.8wt% of spodumene and 4-5wt% of water to prepare a slurry for later use.

[0049] (3) Put the mixture into a disc granulator, and spray the slurry while granulating to obtain granules with a particle diameter of 1-10 mm.

[0050] (4) Dry the granules naturally for 24 hours, then dry them at 100-110°C for 24-48 hours, then raise the temperature to 1300-1400°C, keep them warm for 2-4 hours, cool naturally, and sieve to obtain high-strength microporous mullit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com