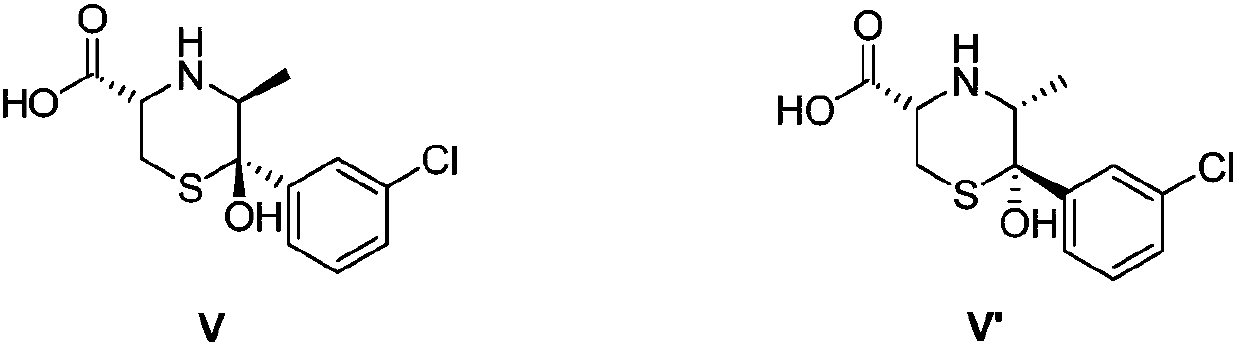

A kind of synthesis method and application of impurity isomers of bupropion hydrochloride sustained-release tablets

A technology of bupropion hydrochloride and a synthesis method, applied in the field of chemical pharmacy, can solve problems such as unfavorable quality control of bupropion hydrochloride, achieve stereospecificity of chirality control, cheap and easily available reagents, and high reaction yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of methyl (S)-2-amino-3-(tritylmercapto)propionate: add 80mL N,N-dimethylformamide and 20g D-cysteine to a 250mL single-neck bottle Methyl ester hydrochloride (compound I, 0.12 mol), stirred at room temperature to dissolve, 45.2 g of triphenylchloromethane (0.16 mol) was added, and reacted at 20-25°C for 48 hours. TLC monitors the complete conversion of raw materials. Add the reaction solution to 180mL 10% sodium acetate solution, stir to obtain a white viscous oil, remove the upper water layer, dissolve the white viscous oil with 200mL dichloromethane, add 40mL saturated sodium chloride solution to wash, divide Go to the water phase. The organic phase was concentrated under reduced pressure to obtain 42.7 g of yellow oil with a yield of 97.1%.

[0056] (2) Preparation of methyl (S)-2-(1-(3-chlorophenyl)-1-oxopropane-2-amino)-3-(tritylmercapto)propionate: 100mL single-neck bottle Add 16mL N,N-dimethylformamide, 10g (S)-2-amino-3-(tritylmercapto) methyl...

Embodiment 2

[0065] (1) Preparation of (S)-2-amino-3-(benzyloxycarbonylmercapto) methyl propionate: add 17.6g D-cysteine methyl ester hydrochloride (compound I, 0.10mol) to a 500mL three-necked flask , 200mL1N NaHCO 3 Dissolve the solution, stir to clear, then add 100mL methyl tert-butyl ether, cool to 0℃, add 17.3g benzyl chloroformate (0.13mol) all at once, stir at 0℃ for 1h, slowly warm up to 10℃, at this temperature Stirring was continued for 1 h, filtered with suction, the filter cake was washed with water, then washed with acetone and methyl tert-butyl ether, and dried under vacuum to obtain 20.7 g of white solid with a yield of 75%.

[0066] (2) Preparation of methyl (S)-2-(1-(3-chlorophenyl)-1-oxopropane-2-amino)-3-(benzyloxycarbonylmercapto)propionate: in a 100mL single-neck bottle Add 16mL N,N-dimethylformamide, 10g (R)-2-amino-3-(benzyloxycarbonylmercapto) methyl propionate (37mmol), stir at room temperature to clear, add 6.7g triethylamine, and then Add 12.7g of 2-bromo-1-(3-ch...

Embodiment 3

[0071] (1) Preparation of (S)-2-amino-3-(benzylmercapto) methyl propionate: add 50 mL of dichloromethane, 20 mL of water, and 10 g of D-cysteine methyl ester hydrochloride to a 250 mL single-mouth bottle (Compound I, 58mmol), 9.6g potassium carbonate, cooling in an ice bath, slowly add 12.2g benzyl bromide (71mmol), remove the ice bath, stir overnight at 35-40°C, separate the liquids, and extract the aqueous phase with dichloromethane 2 Next, the organic phase was washed by adding 20 mL of saturated sodium chloride solution, the aqueous phase was separated, and the organic phase was concentrated under reduced pressure to obtain 11.2 g of yellow oil with a yield of 85.3%.

[0072] (2) Preparation of methyl (S)-2-(1-(3-chlorophenyl)-1-oxopropane-2-amino)-3-(benzylmercapto)propionate: add it to a 100mL single-necked bottle 16mL N,N-dimethylformamide, 10g (R)-2-amino-3-(benzylmercapto) methyl propionate (44mmol), stir to clear at room temperature, add 7.8g potassium carbonate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com