Preparation method of hollow-structured electrode material of lithium ion battery

A technology of lithium-ion batteries and hollow structures, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of further improvement in electrochemical performance, slow diffusion of lithium ions, unfavorable electrochemical performance, etc., to achieve favorable Effects of electron transport, multiple reactive active sites, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: Ternary LiNi 0.8 co 0.1 mn 0.1 o 2 Preparation of hollow microtubes

[0059] The target product of this embodiment is LiNi 0.8 co 0.1 mn 0.1 o 2 , the precipitating agent used is oxalic acid solution, wherein the crystallinity of cobalt oxalate is lower than that of nickel oxalate and manganese oxalate. Therefore, the preparation method is as follows:

[0060] At room temperature, 5 mL of 1 M cobalt acetate solution was added dropwise to 150 mL of 1 M oxalic acid solution, and stirring was continued for 30 min after the addition was completed to fully form a cobalt oxalate precipitate to obtain suspension A. Then 40mL of nickel acetate solution with a concentration of 1M and 5mL of manganese acetate solution with a concentration of 1M were fully mixed, and then added dropwise to the above suspension A while stirring, and continued to stir for 8 hours after the dropwise addition to obtain suspension B. . Suspension B was centrifuged to obtain a pr...

Embodiment 2

[0065] Embodiment 2: Ternary LiNi 0.7 co 0.1 mn 0.2 o 2 Preparation of hollow microtubes

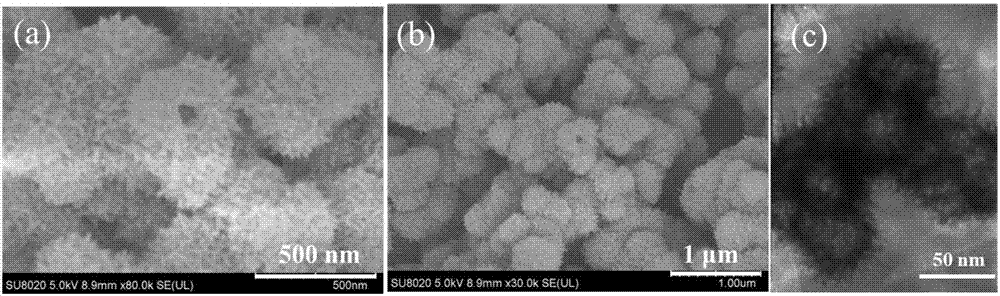

[0066] At room temperature, 20 mL of 0.1 M cobalt chloride solution was added dropwise to 600 mL of 0.1 M oxalic acid solution, and stirring was continued for 2.5 h after the dropwise addition to fully form a cobalt oxalate precipitate to obtain suspension A. Then 140 mL of nickel chloride solution with a concentration of 0.1M and 40 mL of manganese chloride solution with a concentration of 0.1M were fully mixed, and then added dropwise to the above suspension A while stirring, and stirred for 8 hours to obtain suspension B. Suspension B was centrifuged to obtain a precipitate, which was washed with deionized water and ethanol in sequence, and then dried at 80° C. for 12 h to obtain a precursor powder. Figure 7 It is the FESEM image of the precursor powder under different magnifications ( Figure 7 (a) and (b)) and TEM images ( Figure 7 (c)), it can be seen that the obtained prec...

Embodiment 3

[0070] Embodiment 3: Ternary LiNi 0.6 co 0.2 mn 0.2 o 2 Preparation of hollow microtubes

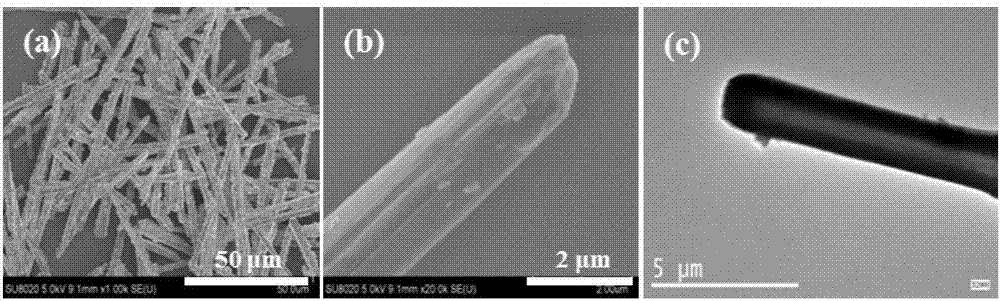

[0071] At room temperature, 60mL of 0.2M cobalt sulfate solution was added to 150mL of 0.4M oxalic acid solution, and stirred for 3 hours to fully form cobalt oxalate precipitate, and suspension A was obtained. Then 20mL of nickel sulfate solution with a concentration of 0.2M and 20mL of manganese sulfate solution with a concentration of 0.2M were fully mixed and added to the above suspension A, and stirred for 8 hours to obtain suspension B. Suspension B was centrifuged, separated to obtain a precipitate, washed with deionized water and ethanol in sequence, and then dried at 50° C. for 20 h to obtain a precursor powder. Figure 12 It is the FESEM image of the precursor powder under different magnifications ( Figure 12 (a) and (b)) and TEM images ( Figure 12 (c)), it can be seen that the obtained precursor is a hollow micron tubular structure.

[0072] The precursor powder and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com