Lithium ion battery positive electrode material and preparation method therefor

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as cycle performance deterioration, structural instability, and easy Jahn-Teller effect, etc., to improve amorphous and service life , electrochemical performance improvement, and the effect of inhibiting irreversible reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) adding aluminum isopropoxide to absolute ethanol to prepare mixed solution I;

[0035] 2) LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The powder is added to the mixed solution prepared in step 1), ultrasonically treated, and continuously stirred to obtain a uniformly mixed suspension, wherein the ultrasonic treatment time is 30 minutes, and the continuous stirring time is 30 minutes;

[0036] 3) MgF 2 Dissolved in absolute ethanol, fully dissolved, and added dropwise to the suspension prepared in step 2) to obtain mixed solution II;

[0037] 4) Mix the mixed solution II prepared in step 3) evenly and place it in an oven at 80°C to completely volatilize the absolute ethanol to obtain the mixture III;

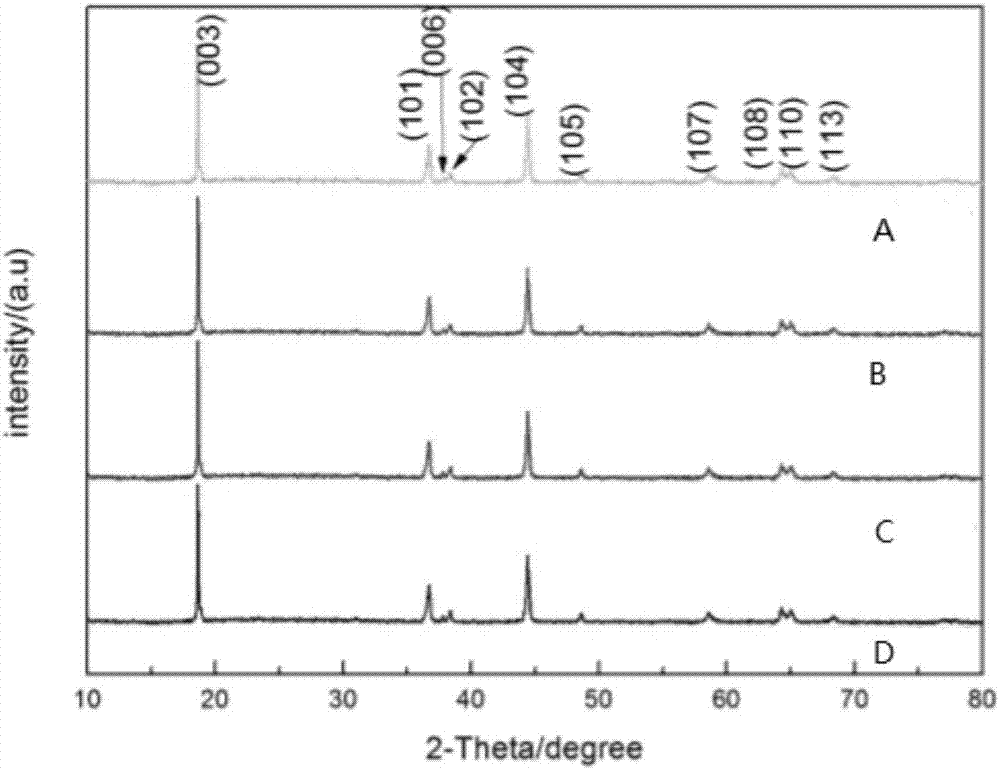

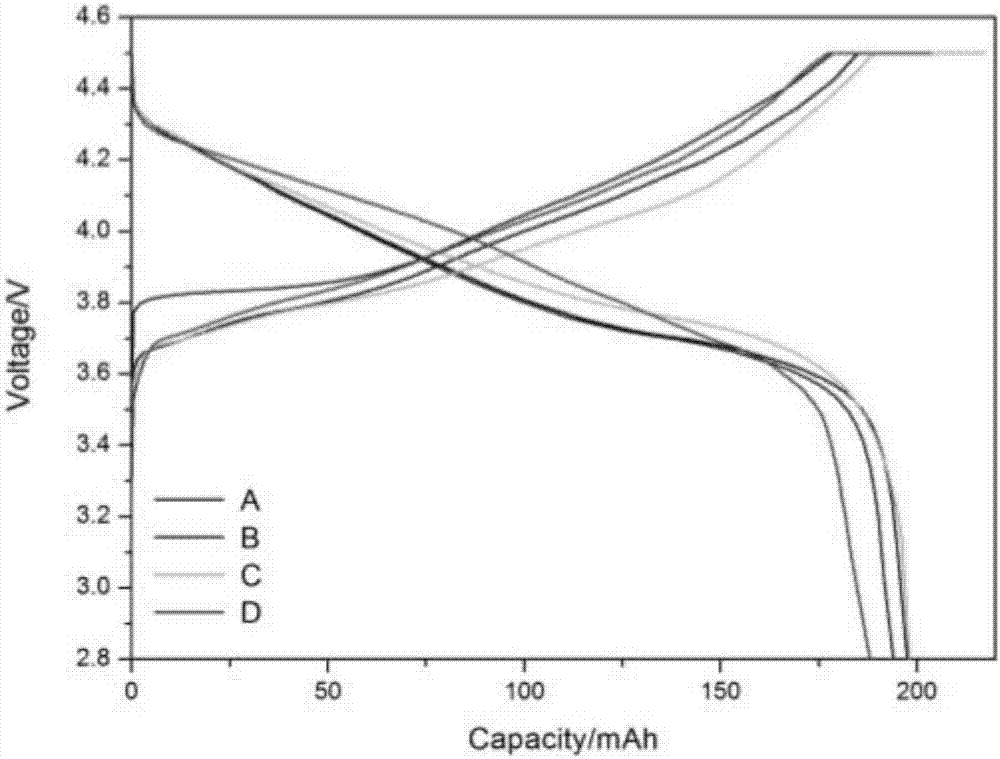

[0038] 5) Place the mixture III prepared in step 4) into a muffle furnace and then cool naturally to prepare Al 2 o 3 and MgF 2 Composite film coated LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material, wherein the calcination temperature is 600°C, and the calcination...

Embodiment 2

[0040] 1) adding aluminum isopropoxide to absolute ethanol to prepare mixed solution I;

[0041] 2) LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The powder is added to the mixed solution prepared in step 1), ultrasonically treated, and continuously stirred to obtain a uniformly mixed suspension, wherein the ultrasonic treatment time is 40 minutes, and the continuous stirring time is 40 minutes;

[0042] 3) MgF 2 Dissolved in absolute ethanol, fully dissolved, and added dropwise to the suspension prepared in step 2) to obtain mixed solution II;

[0043] 4) Mix the mixed solution II prepared in step 3) evenly and place it in an oven at 75°C to completely volatilize the absolute ethanol to obtain the mixture III;

[0044] 5) Place the mixture III prepared in step 4) into a muffle furnace and then cool naturally to prepare Al 2 o 3 and MgF 2 Composite film coated LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material, wherein the calcination temperature is 700°C, and the calcination...

Embodiment 3

[0046] 1) adding aluminum isopropoxide to absolute ethanol to prepare mixed solution I;

[0047] 2) LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The powder is added to the mixed solution prepared in step 1), ultrasonically treated, and continuously stirred to obtain a uniformly mixed suspension, wherein the ultrasonic treatment time is 20 minutes, and the continuous stirring time is 20 minutes;

[0048] 3) MgF 2 Dissolved in absolute ethanol, fully dissolved, and added dropwise to the suspension prepared in step 2) to obtain mixed solution II;

[0049] 4) Mix the mixed solution II prepared in step 3) evenly and place it in an oven at 85°C to completely volatilize the absolute ethanol to obtain the mixture III;

[0050] 5) Place the mixture III prepared in step 4) into a muffle furnace and then cool naturally to prepare Al 2 o 3 and MgF 2 Composite film coated LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material, wherein the calcination temperature is 500°C, and the calcination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com