Polyaniline microrod structure lithium-rich manganese-based positive electrode material as well as preparation method and application thereof

A lithium-rich manganese-based, cathode material technology, applied in the direction of positive electrodes, structural parts, battery electrodes, etc., can solve the problems of low rate performance, large irreversible capacity loss at the first charge and discharge, low cycle stability, etc., to suppress conduction. rate, excellent rate performance and cycle stability, and the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

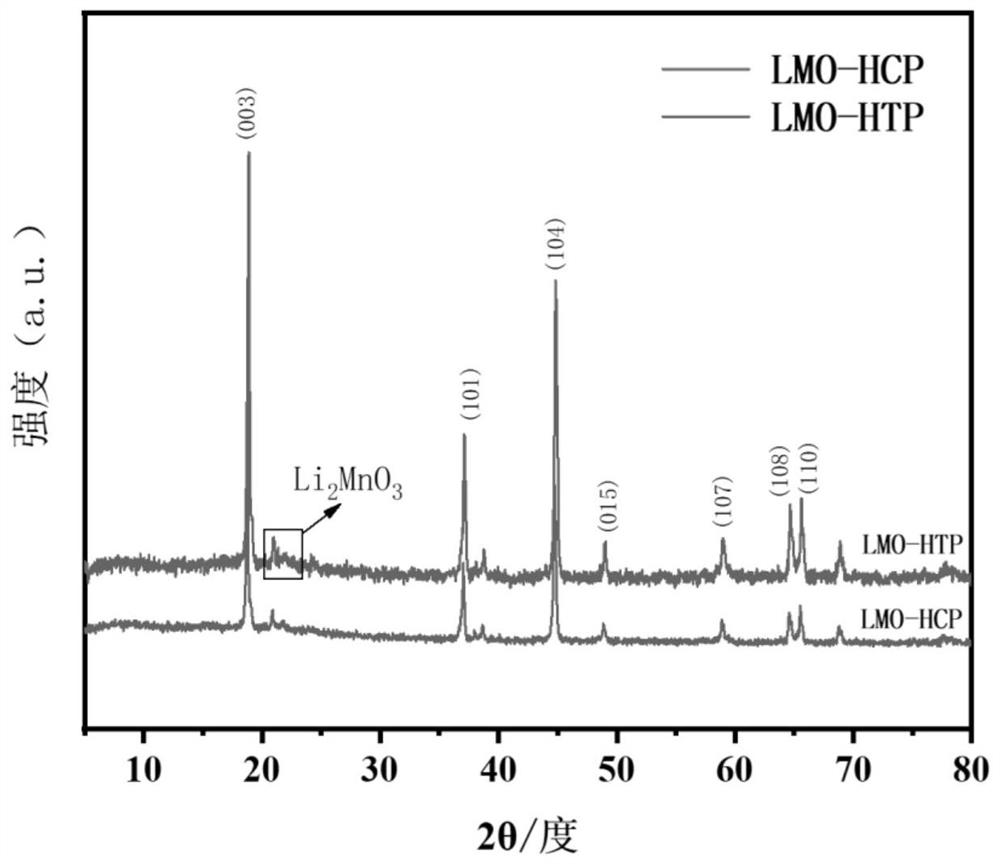

[0062] A polyaniline microrod structure lithium-rich manganese-based cathode material, the mass fraction of polyaniline coating is 0.5%, and the chemical formula of the synthetic target lithium-rich manganese-based oxide is Li 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 @0.5%PANI-HTFSI.

[0063] The preparation method of the above-mentioned polyaniline micro-rod structure lithium-rich manganese-based positive electrode material comprises the following steps:

[0064] Weigh 0.110mol of lithium acetate dihydrate (CH 3 COOLi·2H 2 O), 0.023 mol of cobalt acetate tetrahydrate (Co(CH) 3 COO) 2 ·4H 2 O), 0.023mol nickel acetate tetrahydrate (Ni(CH 3 COO) 2 ·4H 2 O) and 0.043 mol of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 ·4H 2 O) solid, use 50% ethanol solution to configure metal salt solution A with total metal ion concentration of 1mol / L; take 0.25mol oxalic acid, use absolute ethanol as solvent to configure solution B of 1.0mol / L . Subsequently, the metal salt solution ...

Embodiment 2

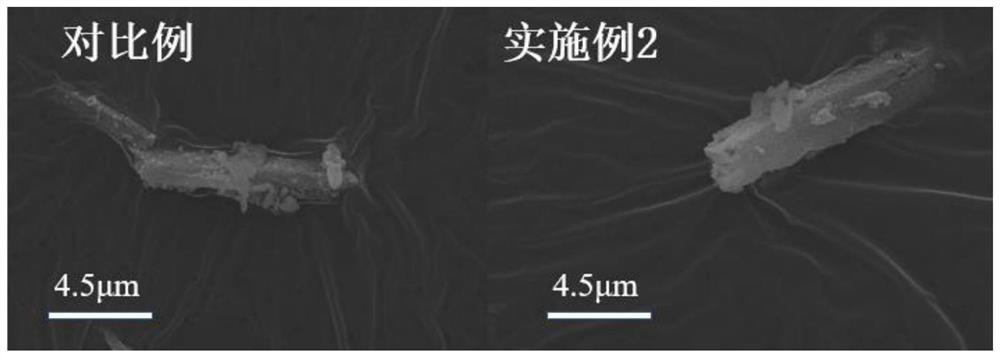

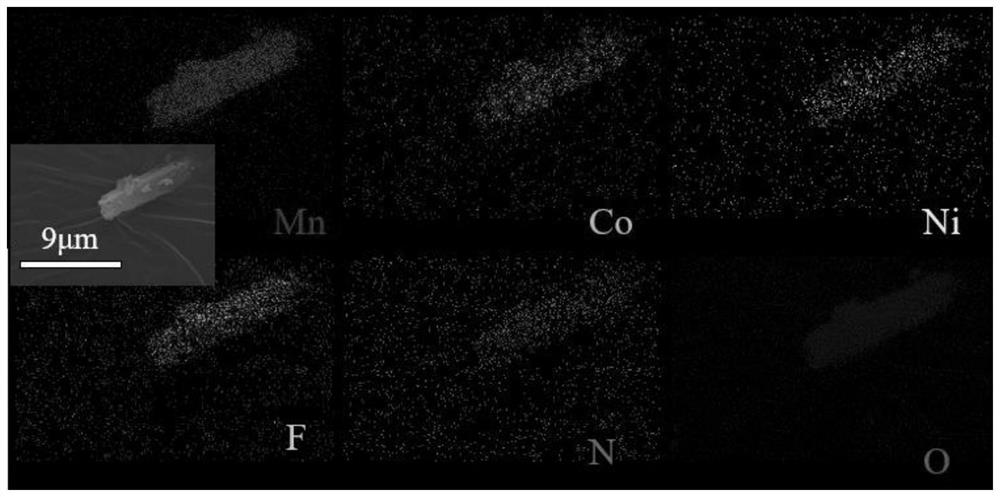

[0068] A polyaniline micro-rod structure lithium-rich manganese-based cathode material, the mass fraction of polyaniline coating is 1%, and the polyaniline-coated rod-shaped lithium-rich manganese-based oxide cathode material is synthesized in HTFSI, Li 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 @1%PANI-HTFSI.

[0069] The preparation method of the polyaniline microrod structure lithium-rich manganese-based positive electrode material is the same as that in Example 1, and the difference is:

[0070] The amount of aniline monomer is 0.005g, wherein the amount of ammonium persulfate is (take the amount of solid powder with a molar mass of aniline monomer 1:1 and dissolve it in an appropriate amount of deionized water, and the concentration is 0.01-0.5mol / L).

Embodiment 3

[0072] A polyaniline micro-rod structure lithium-rich manganese-based cathode material, the mass fraction of polyaniline coating is 1.5%, and the polyaniline-coated rod-shaped lithium-rich manganese-based oxide cathode material is synthesized in HTFSI, Li 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 @1.5% PANI-HTFSI.

[0073] The preparation method of the polyaniline microrod structure lithium-rich manganese-based positive electrode material is the same as that in Example 1, and the difference is:

[0074] The amount of aniline monomer is 0.0075g, wherein the amount of ammonium persulfate is (take the amount of solid powder with a molar mass of aniline monomer 1:1 and dissolve it in an appropriate amount of deionized water, and the concentration is 0.01-0.5mol / L).

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com