Solid-state polymer electrolyte membrane material with continuous ion transfer nanometer channels and preparation method for solid-state polymer electrolyte membrane material

A technology of electrolyte membrane material and solid polymer, which is applied in the field of solid polymer electrolyte membrane material and its preparation, to achieve good mechanical strength, low MPEG content, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

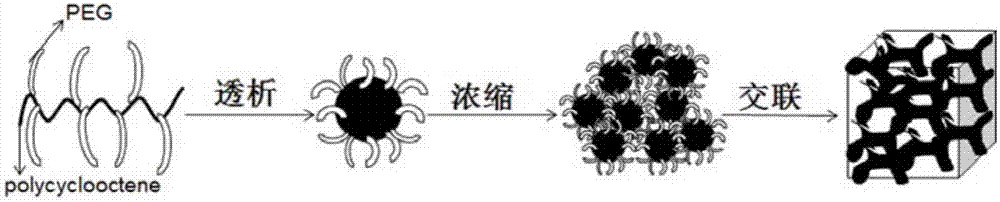

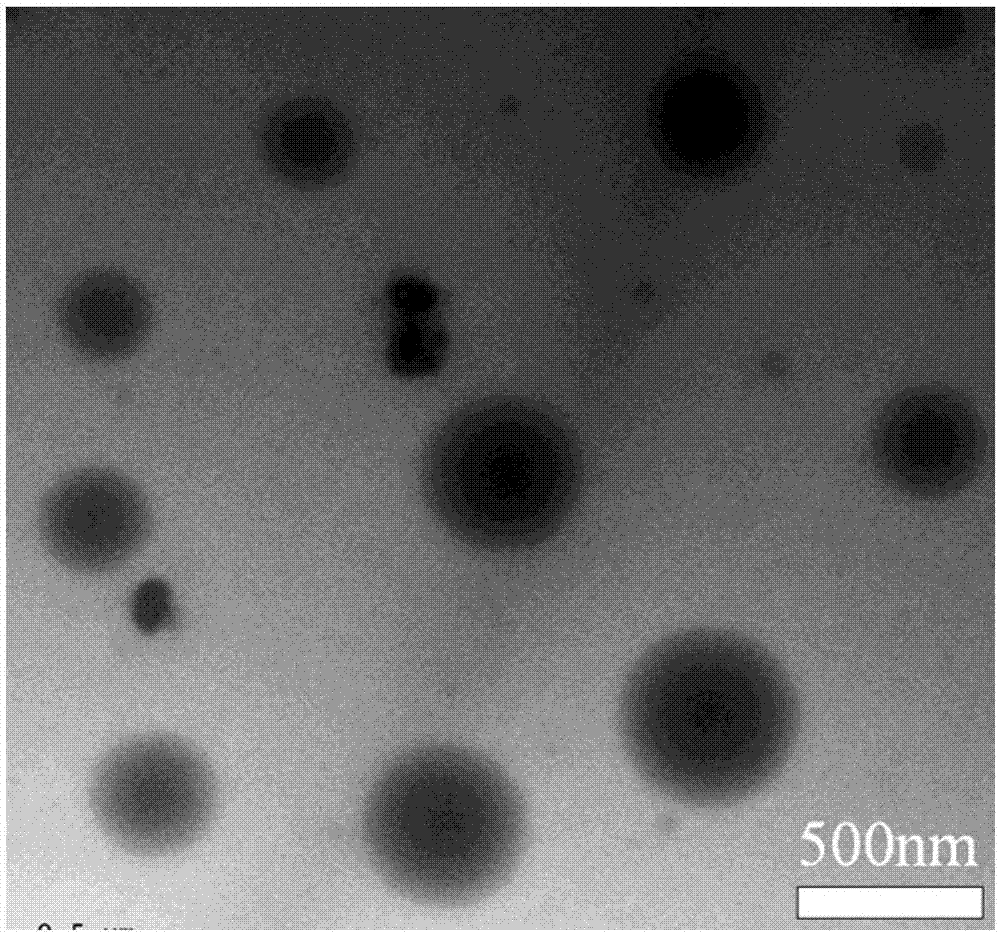

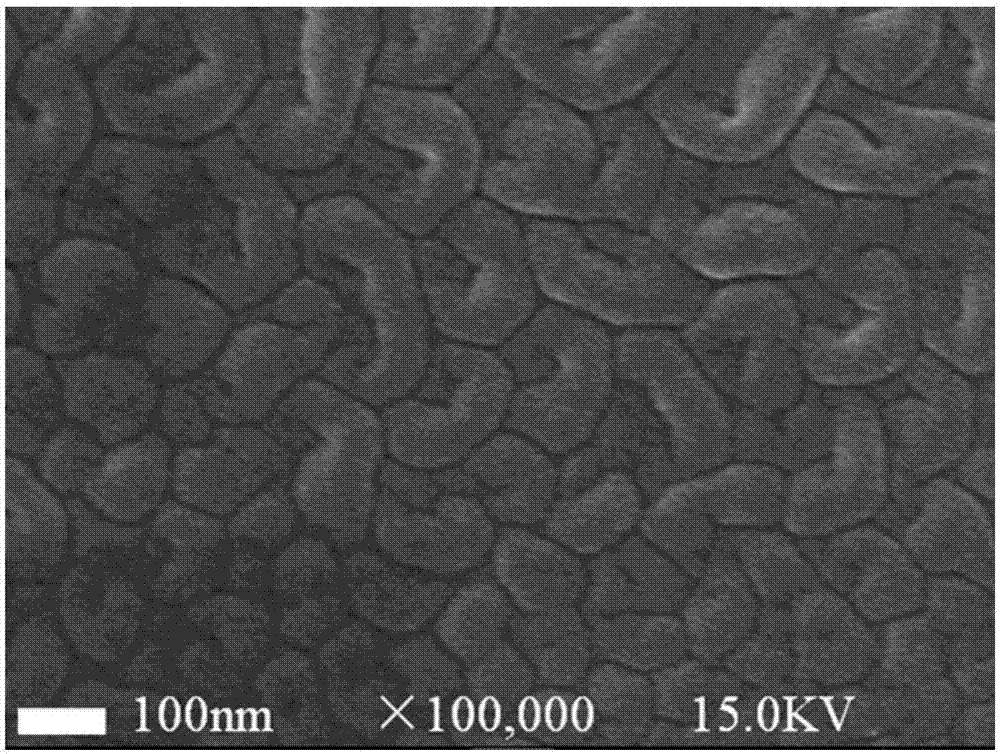

[0038] A solid polymer electrolyte membrane material with continuous ion-transfer nanochannels, which is a comb copolymer (molecular weight of 5,000 to 20,000, wherein The MPEG content is 30wt%, and the relative molecular weight of MPEG is 350). The micelles formed by self-assembly are fused with lithium salt, and the film formed by cross-linking; wherein the micelles are spherical or ellipsoidal in shape, and the size range is about 50nm-500nm.

[0039] The above-mentioned preparation method of the solid polymer electrolyte membrane material with continuous ion transfer nanochannels, the steps are as follows:

[0040] (1) Accurately weigh 0.05g PCOE-g-MPEG (MPEG relative molecular mass is 350, mass fraction is 30%) comb polymer is dissolved in 10g dry co-solvent CH 2 Cl 2 In, obtain the comb copolymer solution that mass fraction is 5 ‰;

[0041] (2) Measure 7.5ml of selective solvent ethanol, add the above-mentioned comb copolymer solution dropwise under stirring at room te...

Embodiment 2

[0049] A method for preparing a solid polymer electrolyte membrane material with continuous ion transfer nanochannels, the steps are as follows:

[0050] (1) Accurately weigh 0.05g PCOE-g-MPEG (MPEG relative molecular mass is 350, mass fraction is 30%) comb polymer is dissolved in 10g dry co-solvent CH 2 Cl 2 In, obtain the solution that mass fraction is 5 ‰;

[0051] (2) Measure 7.5ml of selective solvent ethanol, and add the above solution dropwise under stirring at room temperature, so that the final volume ratio of selective solvent to co-solvent is 1:1;

[0052] (3) Transfer the solution obtained in (2) into a dialysis bag with a molecular weight cut-off of 3500, and dialyze in a large amount of ethanol solution for 3 to 5 days, during which time the dialysate is replaced;

[0053] (4) After the dialysis is completed, fully shake the obtained micellar emulsion, add 0.010g of anhydrous lithium perchlorate to make [Li] / [EO] 1:4, and evaporate the solvent at room temperatu...

Embodiment 3

[0056] A method for preparing a solid polymer electrolyte membrane material with continuous ion transfer nanochannels, the steps are as follows:

[0057] (1) Accurately weigh 0.05g PCOE-g-MPEG (MPEG relative molecular mass is 350, mass fraction is 30%) comb polymer is dissolved in 10g dry co-solvent CH 2 Cl 2 In, obtain the solution that mass fraction is 5 ‰;

[0058] (2) Measure 7.5ml of selective solvent ethanol, and add the above solution dropwise under stirring at room temperature, so that the final volume ratio of selective solvent to co-solvent is 1:1;

[0059] (3) Transfer the solution obtained in (2) into a dialysis bag with a molecular weight cut-off of 3500, and dialyze in a large amount of ethanol solution for 3 to 5 days, during which time the dialysate is replaced;

[0060] (4) After the end of dialysis, fully shake the obtained micellar emulsion, add 0.003g of anhydrous lithium perchlorate to make [Li] / [EO] 1:12, and evaporate the solvent at room temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com