A kind of preparation method of nanostructure composite ultrafiltration membrane

A nanostructure composite, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology and other directions, can solve the problems of difficult to recycle materials, reduce the discharge of waste liquid, fast and effective regulation, and the preparation method is simple and easy. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

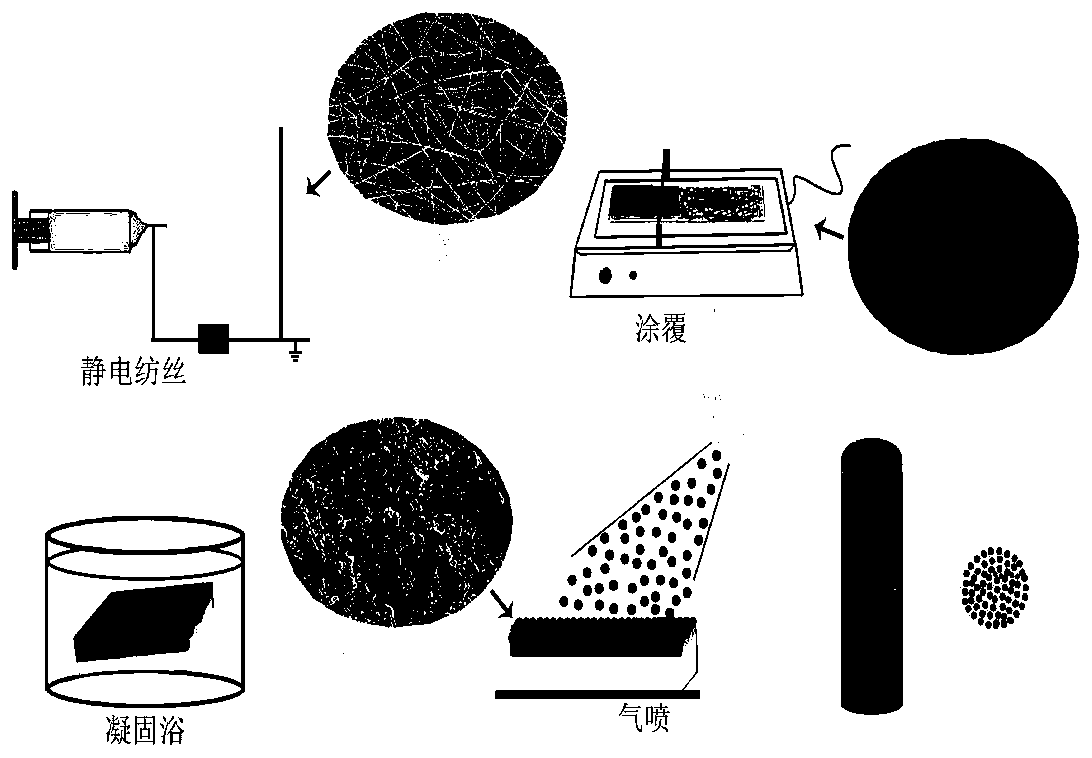

[0031] A preparation method of nanostructure composite ultrafiltration membrane, the concrete steps are:

[0032] (1) Dissolve 0.65g of cellulose acetate (CA) in 5ml of acetone / N,N-dimethylacetamide (DMAc) mixed solution, adjust the volume ratio of acetone / DMAc to 1:1, and keep it at a constant temperature in a water bath at 60°C Heating in the tank for 2h to obtain a transparent and uniform electrospinning solution;

[0033] (2) Dissolve chitosan (CS) in 2% acetic acid aqueous solution, add 2% glycerol to prepare a solution with a total mass fraction of 2.5 wt%, and add a certain amount of polyvinylpyrrolidone (PVP) , the mass ratio of chitosan (CS) and polyvinylpyrrolidone (PVP) is 9:1, the coating solution is placed in a 60°C water bath to heat and dissolve, and stirred evenly to obtain a uniform and transparent coating solution;

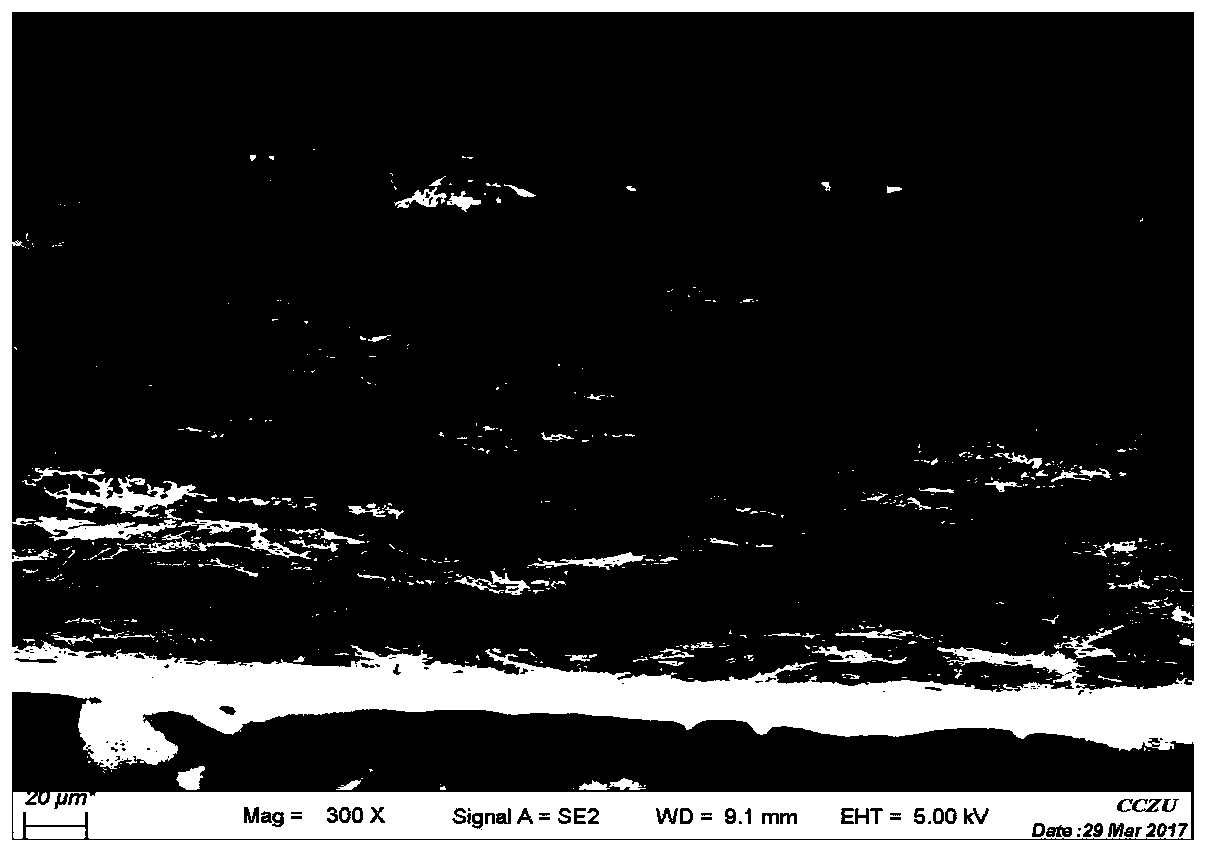

[0034] (3) The electrospinning solution in step (1) was added to the syringe, and the extrusion was controlled by a micro-syringe pump. The noz...

Embodiment 2

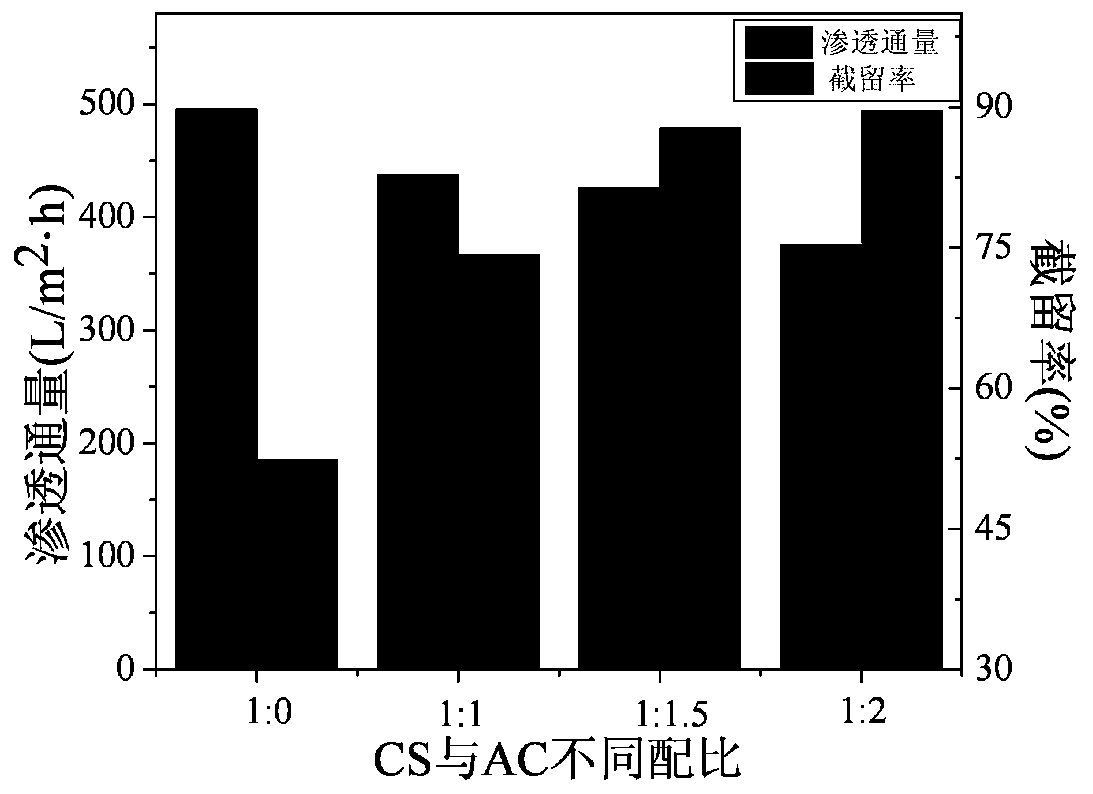

[0038] The preparation method of the nanostructure composite ultrafiltration membrane is similar to that in Example 1, except that in the step (4), the mass ratio of chitosan (CS) and activated carbon (AC) powder is 1:0 respectively. , 1:0.5, 1:1, 1:2.

[0039]The CA / CS / AC nanostructure composite membrane prepared in Example 1-2 was subjected to cross-flow filtration test on bisphenol A (BPA): when the mass ratios of chitosan (CS) and activated carbon (AC) powder were respectively At 1:0, 1:1, 1:1.5, and 1:2, the prepared nanostructured composite membrane was tested for cross-flow filtration of 0.1 mmol / L bisphenol A (BPA), and the filtration operating pressure was 0.2 MPa , the corresponding permeation flux is 495.4L / m 2 h, 437.0L / m 2 h, 425.6L / m 2 h, 374.6L / m 2 ·h, the retention rates were 52.4%, 74.3%, 87.8%, and 89.6%, respectively. It can be seen that when the mass ratio of CS / AC is 1:1.5, the filtration performance of the prepared CA / CS / AC nanostructured composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com