A kind of polarized styrene thermoplastic elastomer and its preparation method and application

A thermoplastic elastomer and styrene-based technology, which is applied in the field of polarized styrene-based thermoplastic elastomer and its preparation, can solve the problems of few successful cases, improve material toughness, obtain raw materials, and improve impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

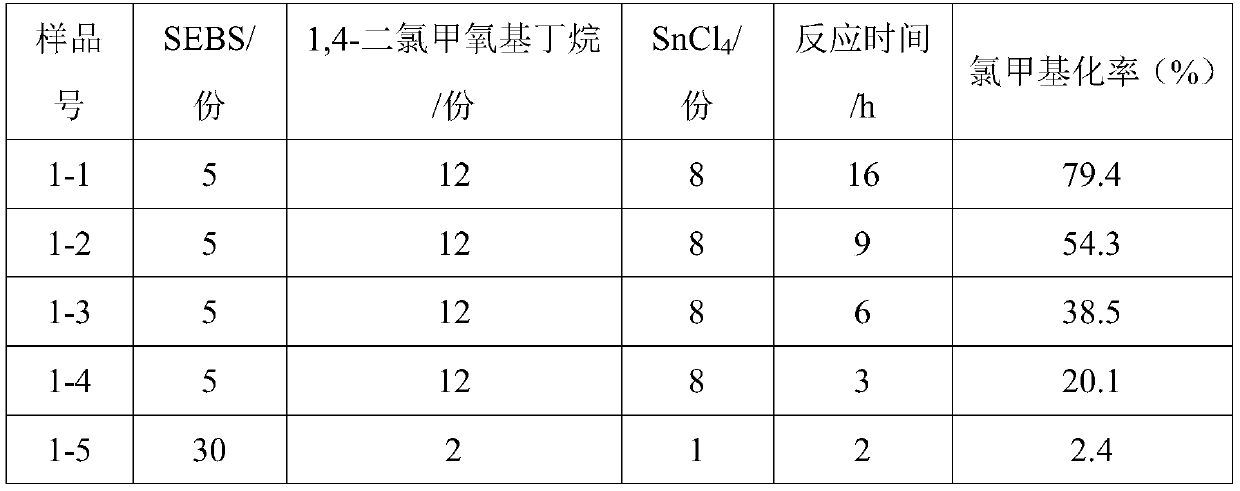

[0027] Preparation of halomethylated styrene thermoplastic elastomers:

[0028] Chloromethylation of Styrene Thermoplastic Elastomer (SEBS YH-501)

[0029] The formula and chloromethylation rate of SEBS are shown in Table 1. According to the formula in Table 1, SEBS YH-501 and tin tetrachloride were successively added to a three-necked flask filled with 250 parts of chloroform to control SEBS. The mass concentration does not exceed 10%, and the stirring is started. Then add 1,4-dichloromethoxybutane into the constant pressure dropping funnel, slowly drop 1,4-dichloromethoxybutane into the flask, control the reaction temperature not to exceed 20°C, and react for a period of time After the reaction, ethanol was added to the reaction system to precipitate chloromethylated SEBS, washed repeatedly with chloroform / ethanol for at least 3 times, and finally dried to obtain the product chloromethylated SEBS.

[0030] Table 1

[0031]

[0032] Bromomethylation of Styrene Thermopla...

Embodiment 1

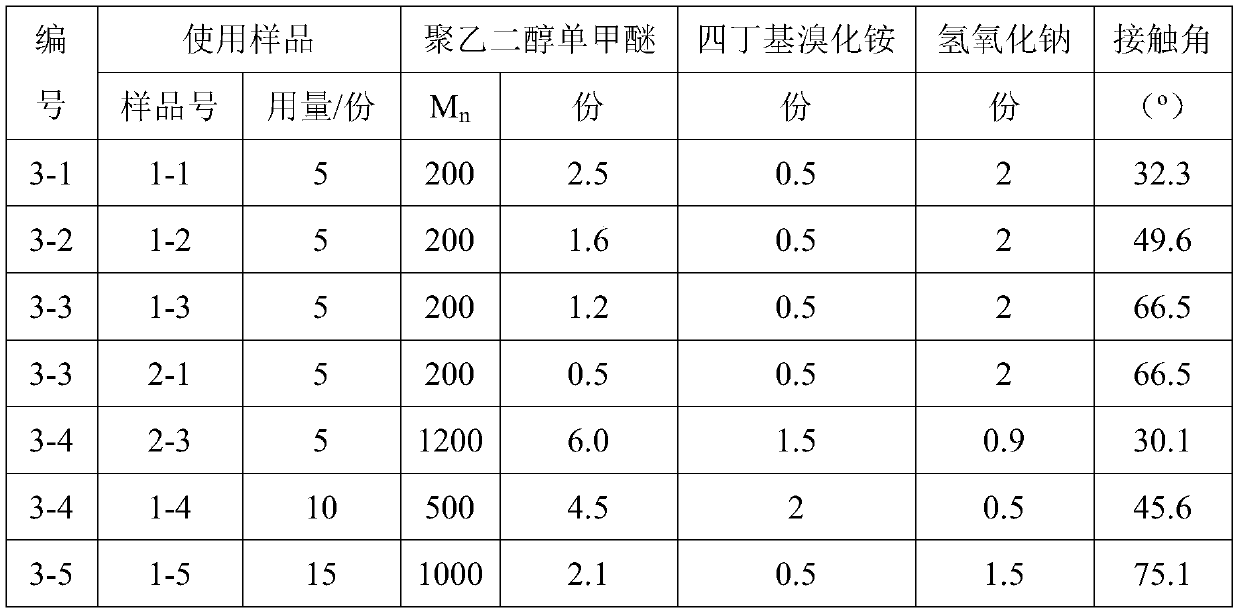

[0038] A preparation method of polarized styrene thermoplastic elastomer, comprising the steps of:

[0039] (1) Preparation of toluene solution of halomethylated styrene thermoplastic elastomer: add halomethylated styrene thermoplastic elastomer to a flask containing 150 parts of toluene to prepare halomethylated styrene thermoplastic elastomer Toluene solution, the control mass concentration is not more than 10%;

[0040] (2) Preparation of an alkaline aqueous solution containing a phase transfer catalyst: at normal temperature, add metered tetrabutylammonium bromide to 2 parts of deionized water, and after all dissolve, add metered polyethylene glycol monomethyl ether, Metered sodium hydroxide, after all dissolving, obtains the alkaline aqueous solution containing phase transfer catalyst;

[0041] (3) adding the alkaline aqueous solution containing the phase transfer catalyst into the toluene solution of the halomethylated styrene thermoplastic elastomer, reacting at 60° C....

Embodiment 2

[0048] Add bromomethylated SEPS to a flask containing 100 parts of toluene to prepare a bromomethylated SEPS toluene solution, and control the mass concentration to not exceed 10%. Add measured amounts of cetyltrimethylammonium bromide (CTAB), measured amounts of polypropylene glycol monomethyl ether, and measured amounts of potassium hydroxide to 4 parts of deionized water to prepare an alkaline aqueous solution. Add the aqueous alkali solution to the bromomethylated SEPS toluene solution, and react at 40°C for 24 hours. After finishing, add methanol to precipitate the product and dry it to obtain polarized SEPS. The formula and contact angle of polarized modification of SEPS are shown in Table 4:

[0049] Table 4

[0050]

[0051] The polarized styrenic thermoplastic elastomer prepared by the present invention has remarkable effect, the contact angle is 30-90°, and because the elastomer contains both polyether molecular side chains and long fatty main chains, it has exce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com