Method for manufacturing allulose-containing sweetener composition

A manufacturing method and technique of psicose are applied in the field of manufacturing sweetener compositions containing glucose, fructose and psicose, which can solve problems such as difficulties, unresearched control factors, difficulty in enzymatic reaction control, etc. The effect of less investment burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0102] Preparation of immobilized enzyme and determination of immobilized enzyme activity

[0103] Commercially available immobilized glucose isomerase was obtained from Nagase ChemteX Corporation (product name: Suitaze GN). The product is a granular preparation obtained by immobilizing microorganisms having glucose isomerase activity on a carrier, and the specific activity after swelling is 110.43 U / ml.

[0104] In the case of independently preparing the immobilized glucose isomerase, it is carried out through the following steps. First, 50 ml of ion exchange resin (manufactured by Purolite Corporation, trade name: PUROLITE A103S) was packed into a column, washed with 50 mM phosphate buffer (pH 8.0) containing 2 mM magnesium sulfate, and then isomerized liquid glucose containing 4500 U Glucose isomerase was adsorbed by circulating 500 ml of 50 mM phosphate buffer solution (pH 8.0) containing 2 mM magnesium sulfate (manufactured by Dow Chemical Company, product name: Spezym...

Embodiment 1

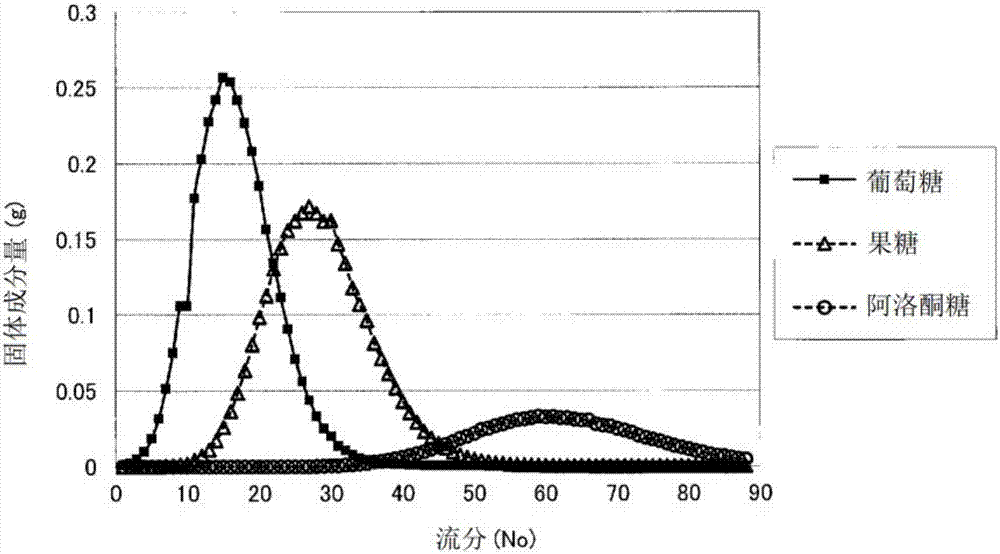

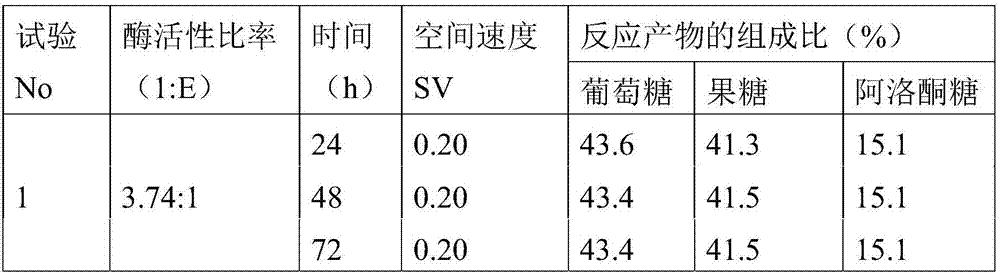

[0107] The glucose solution was passed through the column packed with immobilized glucose isomerase and immobilized psicose epimerase Confirmation of obtained sweetener composition (under the condition of space velocity SV=0.2)

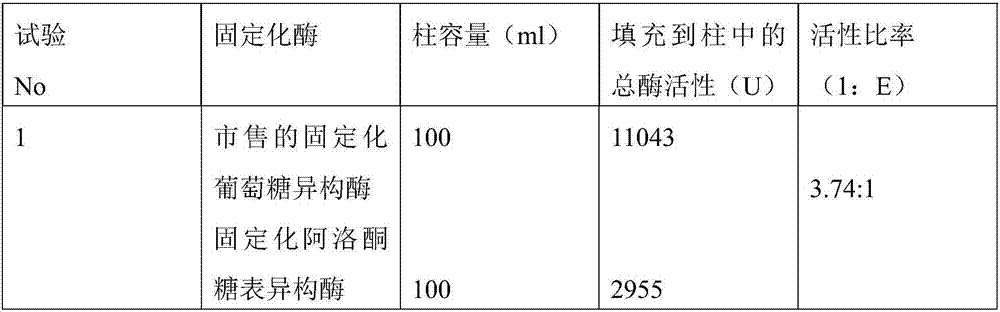

[0108] Commercially available immobilized glucose isomerase prepared in Production Example 1 or immobilized immobilized glucose isomerase and immobilized psicose epimerase prepared in-house were prepared in accordance with the amount and activity ratio shown in Table 1. Mix uniformly by method, and fill in a glass column with a jacketed inner diameter of 32 mm and a length of 300 mm.

[0109] [Table 1]

[0110] Activity ratio of the mixed 2 immobilized enzymes

[0111]

[0112] A 35% by mass glucose solution whose pH was adjusted to 7.8 to 8.0 by adding 2 mM magnesium sulfate and sodium carbonate was prepared. The glucose solution was continuously passed through the column in an upward flow while controlling so that the jacket temperature bec...

Embodiment 2

[0118] Effects of the mixing ratio of immobilized glucose isomerase and immobilized allulose epimerase on glucose, fructose and allulone Influence of sugar composition ratio (under the condition of space velocity SV=0.3~0.4)

[0119] The commercially available immobilized glucose isomerase prepared in Production Example 1 or the immobilized immobilized glucose isomerase and immobilized psicose epimerase prepared in-house were prepared in accordance with the amount and activity ratio shown in Table 3. Mix uniformly by method, and fill in a glass column with a jacketed inner diameter of 32 mm and a length of 300 mm.

[0120] [table 3]

[0121] Activity ratio of the mixed 2 immobilized enzymes

[0122]

[0123] A 35% by mass glucose solution whose pH was adjusted to 7.8 to 8.0 by adding 2 mM magnesium sulfate and sodium carbonate was prepared. The glucose solution was continuously passed through the column in an upward flow while controlling the jacket temperature to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com