Preparation method for water-soluble quaternary ammonium ion fluorescent carbon dot

A technology of quaternary ammonium cation and fluorescent carbon dots, which is applied in the field of carbon dot materials, can solve the problems of being unsuitable for large-scale production of quaternized ammonium salted fluorescent carbon dots and the high cost of raw materials, and achieves a technology that is favorable for popularization, simple in preparation process and effective in utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

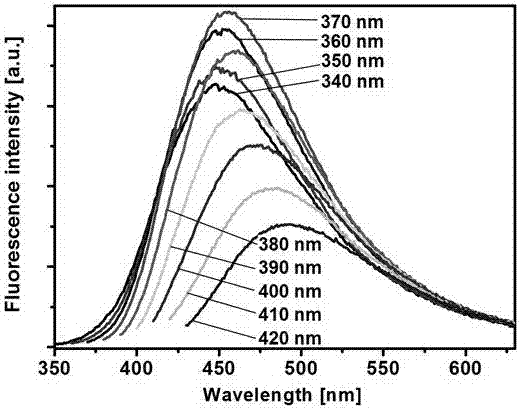

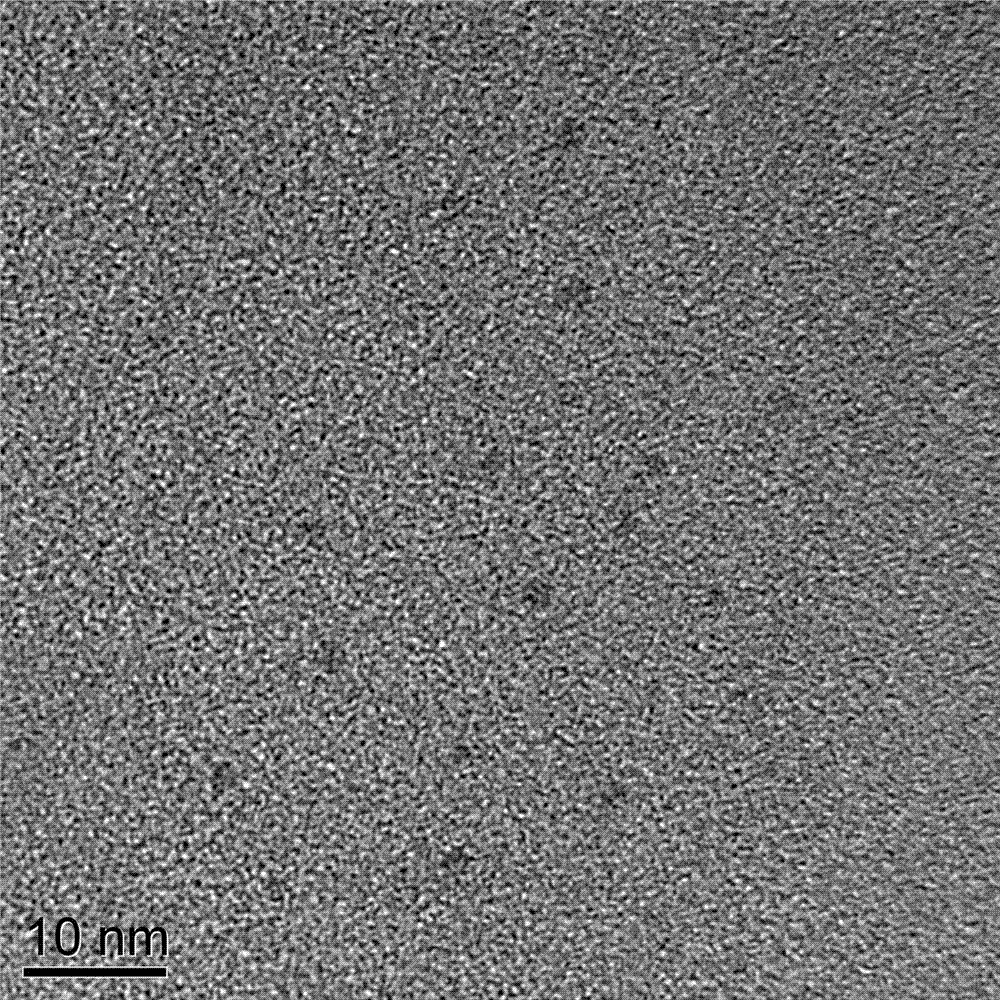

Image

Examples

Embodiment 1

[0031] The preparation method of the water-soluble quaternary ammonium cationic fluorescent carbon dot of the present embodiment comprises the following steps:

[0032] 1) Add 1g of sodium carboxymethylcellulose and 1mL of 4,7,10-trioxy-1,13-tridecanediamine into 50mL of water, mix well, and perform hydrothermal reaction in a hydrothermal reactor. The reaction temperature was 200°C, and the reaction time was 12 hours. After the reaction, it was cooled to room temperature, and the reaction solution was dialyzed with a 3500Da dialysis bag to obtain an aqueous solution of carboxylated fluorescent carbon dots with a solid content of 2% on the surface rich in carboxyl groups;

[0033] 2) Add 1g of 4-dimethylaminopyridine and 6g of 3-chloro-2-hydroxypropyltrimethylammonium chloride to the aqueous solution of carboxylated fluorescent carbon dots obtained in step 1), mix well, and then add 110mL of Dimethyl sulfoxide solution of N,N'-dicyclohexylcarboximide, containing 6.6g of N,N'-di...

Embodiment 2

[0035] The preparation method of the water-soluble quaternary ammonium cationic fluorescent carbon dot of the present embodiment comprises the following steps:

[0036] 1) Add 4g of sodium carboxymethylcellulose and 6mL of 4,7,10-trioxy-1,13-tridecanediamine into 100mL of water, mix well, and perform hydrothermal reaction in a hydrothermal reactor. The reaction temperature was 150°C, and the reaction time was 24 hours. After the reaction, it was cooled to room temperature, and the reaction solution was dialyzed with a 4000Da dialysis bag to obtain an aqueous solution of carboxylated fluorescent carbon dots with a solid content of 5% on the surface rich in carboxyl groups;

[0037] 2) Add 2g of 4-dimethylaminopyridine and 3g of 3-chloro-2-hydroxypropyltrimethylammonium chloride to the aqueous solution of carboxylated fluorescent carbon dots obtained in step 1), mix well, and then add 205mL of N,N'-dicyclohexylcarbimide in dimethyl sulfoxide solution, the solution contains 11.7g...

Embodiment 3

[0039] The preparation method of the water-soluble quaternary ammonium cationic fluorescent carbon dot of the present embodiment comprises the following steps:

[0040] 1) Add 8g of sodium carboxymethyl cellulose and 10mL of 4,7,10-trioxy-1,13-tridecanediamine into 200mL of water, mix well, and carry out hydrothermal reaction in a hydrothermal reactor. The reaction temperature was 240°C, and the reaction time was 8 hours. After the reaction, it was cooled to room temperature, and the reaction solution was dialyzed with a 5000Da dialysis bag to obtain an aqueous solution of carboxylated fluorescent carbon dots with a solid content of 6% on the surface rich in carboxyl groups;

[0041]2) Add 3g of 4-dimethylaminopyridine and 8g of 3-chloro-2-hydroxypropyltrimethylammonium chloride to the carboxylated fluorescent carbon dot aqueous solution obtained in step 1), mix well, and then add 280mL of N, N'-dicyclohexyl carboximide in dimethyl sulfoxide solution, the solution contains 10g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com