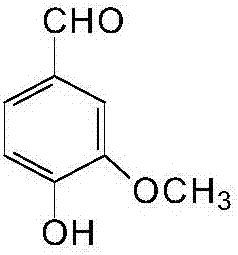

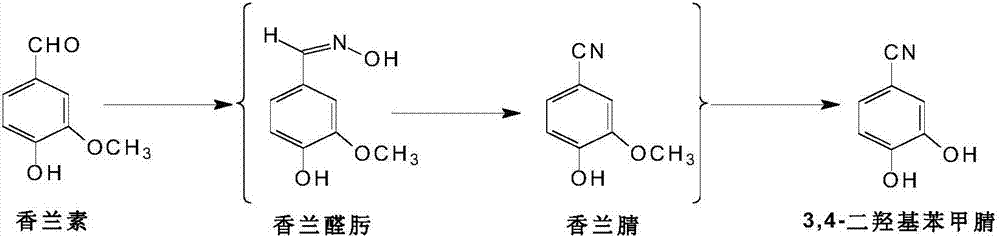

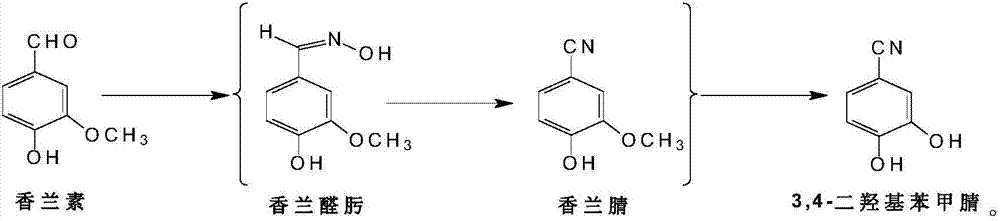

Preparation method of 3, 4-dihydroxybenzonitrile

A technology of hydroxybenzonitrile and dimethylformamide, which is applied in the field of preparation of 3,4-dihydroxybenzonitrile, can solve the problems of being unsuitable for industrial production, cumbersome methods, difficult source of raw materials, etc., so as to shorten the production cycle , The process is simple and the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: preparation of vanilla nitrile:

[0035]In a 500ml four-neck flask, add 152.0g vanillin, 125.1g hydroxylamine hydrochloride, and 304ml N,N-dimethylformamide in sequence, stir and mix; heat the oil bath slowly until the inner temperature is about 50°C, and keep the reaction 4 hours; heat slightly, the internal temperature rises to 110°C, and then keep warm for 2 hours; after the reaction is completed, slowly pour the reaction mixture into 1000ml of normal water, stir and crystallize until complete; filter, dry, and get off-white crystalline powder The dry product of vanillin nitrile is 141.69g, yield: 95.1%, melting point: 87.5~88.0°C, purity: 99.30%.

Embodiment 2

[0036] Embodiment 2: preparation of vanilla nitrile

[0037] According to the method of Example 1, 152.0 g of vanillin, 104.25 g of hydroxylamine hydrochloride, and 228 ml of dimethyl sulfoxide were mixed, and the internal temperature was 60 ° C, and the reaction was kept for 4 hours; the inner temperature was raised to 120 ° C, and the reaction was kept for 2 hours; After the reaction is over, the reaction mixture is slowly poured into 1000ml of normal water, stirred and crystallized until complete; filtered and dried to obtain 129.01g of vanilla nitrile dry product in the form of off-white crystalline powder, yield: 86.5%, melting point: 85.5~ 86.0°C, purity: 98.5%.

Embodiment 3

[0038] Embodiment 3: 3,4-dihydroxybenzonitrile preparation

[0039] In a 1000ml four-neck flask, add 120g of vanillin nitrile and 300ml of N,N-dimethylformamide prepared in Example-1 in sequence, stir and mix until the solid dissolves; under cooling, slowly add 145.15g of anhydrous aluminum trichloride, At the same time, when the internal temperature naturally rises to 90°C, the water bath controls the internal temperature to not exceed 120°C to finish adding anhydrous aluminum trichloride; The solution was added to dilute hydrochloric acid and hydrolyzed; the toluene was extracted several times, and the water layer was discarded; the toluene layer was washed with normal water, concentrated under reduced pressure, and the residue was recrystallized with dilute alcohol aqueous solution to obtain a white crystalline solid, which was dried in vacuo to obtain a 95.62 g of 3,4-dihydroxybenzonitrile in the form of white crystalline solid powder, yield: 87.95%, melting point: 155.5-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com