Recombinant bacterium of synthesizing 3-hydracrylic acid, construction method and application of recombinant bacterium

A technology of hydroxypropionic acid and recombinant bacteria, applied in the field of genetic engineering, can solve problems such as hindering the production of 3-hydroxypropionic acid, and achieve the effects of increasing yield and improving tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Construction of embodiment 1 recombinant strain

[0052] 1) Construction of vector pETDuet-clpP

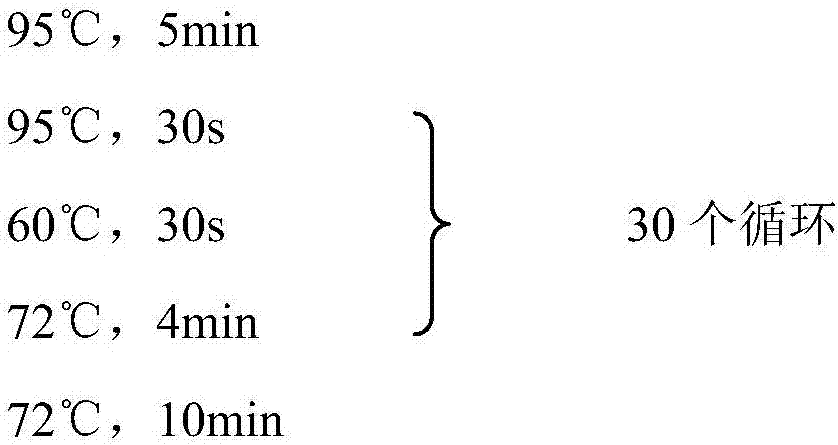

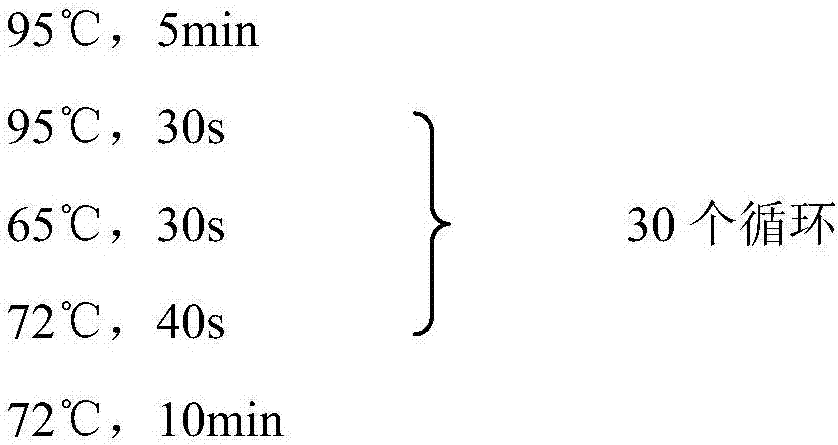

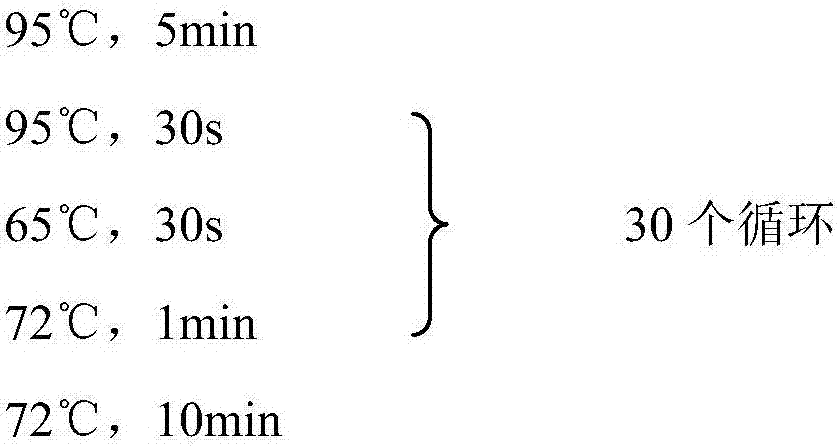

[0053] In this example, the malonyl-CoA reductase gene mcr (the protein number of MCR in NCBI is AAS20429.1) derived from C. aurantiacus was obtained by PCR amplification using the C. aurantiacus genome as a template (Primers: 5'-CATGGTACCAGCGGAACAGGACGAC-3' and 5'-CCCTCGAGGAATTTACACGGTAATCGC-3'), the specific amplification procedure is as follows:

[0054]

[0055] After the PCR, 1% (wt / v) agarose gel electrophoresis was performed, and the target fragment with a size of about 3700 bp was recovered by using a recovery kit (OMEGA GelExtraction Kit).

[0056] The obtained mcr gene fragment and plasmid pETDuet-1 were double digested with KpnI and XhoI restriction endonucleases at 37°C for 3.5 hours, and the digested products were subjected to 1% (wt / v) agarose gel electrophoresis, and then Use the recovery kit (OMEGAGel Extraction Kit) to recover the digested product, con...

Embodiment 2

[0080] Embodiment 2 fermentation produces 3-hydroxypropionic acid

[0081] The monoclonal engineered strain obtained is activated in LB culture, and the activated seed liquid is inoculated into a 250mL shake flask containing 100mL of basic modified liquid medium according to the ratio of seed liquid: basic modified liquid medium volume ratio of 1:100 (Contains 100μg·mL -1 Ampicillin and 100 μg·mL -1 Chloramphenicol), cultured with shaking at 37°C and 180rpm. OD 600 When reaching about 0.6, the temperature was adjusted to 30°C, and 0.05mM IPTG was added for induction. Thereafter, 0.05mM IPTG, 100mg / mL ampicillin and 100μg·mL -1 Chloramphenicol, 48h after the initial induction of IPTG, the fermentation was terminated.

[0082] Take 1 mL of fermentation broth, centrifuge at 15,000 rpm for 10 min at 4°C, take the supernatant, and detect the product concentration by high-performance liquid chromatography. Using an ultraviolet detector, the 3-HP yield is 6.7 g / L. Compared with...

Embodiment 3

[0084] The single clone of the obtained engineering strain was activated in LB culture, and the activated strain was inoculated into a 250mL shake flask containing 100mL basic modified liquid medium (containing 100μg·mL-1 ampicillin and 100 μg·mL-1 chloramphenicol), shaking at 37°C and 220 rpm. When OD600 reached about 0.8, the temperature was adjusted to 33°C, and 0.1mM IPTG was added for induction. Thereafter, 0.1 mM IPTG, 100 mg / mL ampicillin and 100 μg·mL-1 chloramphenicol were added every 12 h, and the fermentation was terminated 24 h after the initial induction of IPTG.

[0085] Take 1 mL of fermentation broth, centrifuge at 15,000 rpm for 10 min at 4°C, take the supernatant, and detect the product concentration by high-performance liquid chromatography. Using an ultraviolet detector, the 3-HP yield is 3.5 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com