A recombinant bacterium utilizing dextran to synthesize 3-hydroxypropionic acid and its construction method and application

A technology of hydroxypropionic acid and recombinant bacteria, which is applied in the field of genetic engineering, can solve the problems of limited yield and limited utilization of 3-hydroxypropionic acid substrate, and achieve the effect of increasing yield and substrate utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Construction of embodiment 1 recombinant strain

[0050] 1) Construction of recombinant vector puC18-lgk

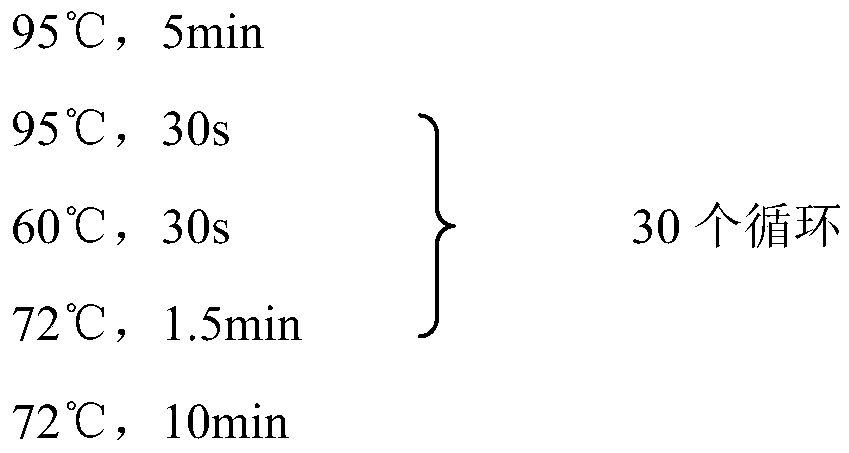

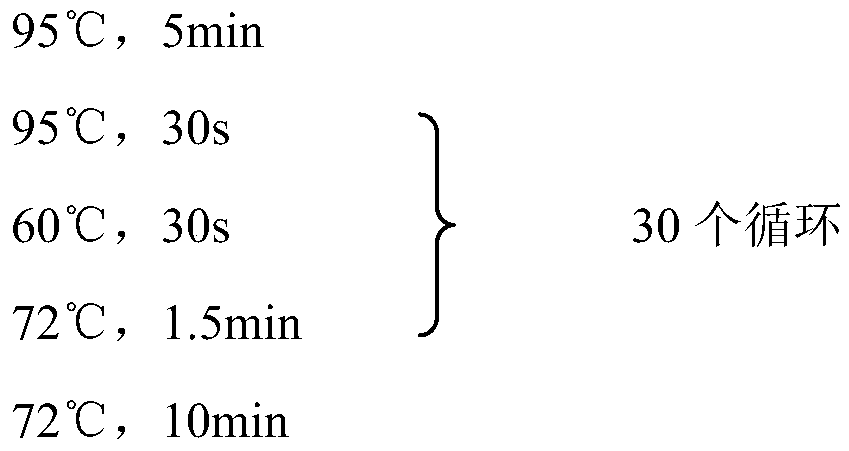

[0051] In this example, codon optimization is performed on the gene lgk (the nucleotide number in NCBI is KU377145.1) derived from the levoglucosanokinase of L. starkeyi; the original gene is imported into the website http: / / www.jcat.de / Start.jsp In the process, the commonly used enzyme cutting sites were eliminated, and the optimized gene sequence was obtained after replacing rare codons. The optimized gene sequence was used as a template to synthesize the gene, and its sequence is shown in SEQ ID NO.1. Using the gene obtained by gene synthesis as a template, the gene fragment was obtained by PCR amplification (primers: 5'-CGGGATCCATGCCGATCGCTACCTCTAC-3' and 5'-GCTCTAGATTAAGCCCAGTTGTTGGTGAT-3'); the specific amplification procedure is as follows:

[0052]

[0053] After the PCR, 1% (wt / v) agarose gel electrophoresis was performed, and the target fragment wi...

Embodiment 2

[0065] Embodiment 2 fermentation produces 3-hydroxypropionic acid

[0066] The engineering strain monoclonal that embodiment 1 obtains is activated in LB culture, and the seed liquid after activation is by seed liquid: the ratio of fermentation medium volume ratio 1:130 is inoculated in the 250mL shake flask that contains the fermentation medium of 100mL ( Contains 100μg·mL -1 Kanamycin), cultured with shaking at 35°C and 180rpm. OD 600 When it reaches about 0.8, add 0.1mMIPTG to induce, and continue to cultivate at 37°C. Thereafter, the pH was adjusted to 7 with ammonia water every 12 hours, and the fermentation was terminated 24 hours after the initial induction.

[0067] Take 1 mL of fermentation broth, centrifuge at 15,000 rpm for 10 min at 4°C, take the supernatant, and detect the product concentration by high-performance liquid chromatography. Using an ultraviolet detector, the 3-HP yield is 0.8 g / L.

Embodiment 3

[0068] Embodiment 3 fermentation produces 3-hydroxypropionic acid

[0069] The engineering strain monoclonal that embodiment 1 obtains is activated in LB culture, and the seed liquid after activation is by seed liquid: the ratio of fermentation medium volume ratio 1:100 is inoculated in the 250mL shake flask that contains the fermentation medium of 100mL ( Contains 100μg·mL -1 Kanamycin), cultured with shaking at 37°C and 180rpm. OD 600 When reaching about 0.6, the temperature was adjusted to 30°C, and 0.01 mM IPTG was added for induction. Thereafter, the pH was adjusted to 7 with ammonia water every 12 hours, and the fermentation was terminated 48 hours after the initial induction.

[0070] Take 1 mL of fermentation broth, centrifuge at 15,000 rpm for 10 min at 4°C, take the supernatant, and detect the product concentration by high-performance liquid chromatography. Using an ultraviolet detector, the 3-HP yield is 1.1 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com