Preparation method of hydrophilic polyvinylidene fluoride (PVDF) hybrid membrane

A polyvinylidene fluoride, hydrophilic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of unstable hydrophilic performance of separation membranes, and achieve the effect of protein reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) KH-230 to ZrO 2 Nanoparticle treatment: weigh 5g dry ZrO 2 Nanoparticles were placed in 100 ml of toluene, ultrasonically dispersed for 30 min, then 30 ml of γ-chloromethyltriethoxysilane (KH-230) was added, and refluxed at 80 °C for 24 h. After the reaction, the reaction solution was centrifuged, the product was repeatedly washed with absolute ethanol and pure water three times, and dried in an oven at 60°C for 24 hours to obtain ZrO 2 -Cl nanoparticles.

[0037] (2) ZrO 2 - Synthesis of g-PDMAEMA: Weigh 2 g of dry ZrO 2 -Cl is immersed in 100 ml N-methylpyrrolidone (NMP) solvent, and the protective agent N 2 After ultrasonication for 30 min, 0.025 mol of DMAEMA monomer, 300 μl of PMDETA, and 0.12 g of CuCl were added, and vacuumed with a vacuum pump. React in an oil bath at 70°C for 24 hours under airtight conditions. After the reaction, the reaction solution was centrifuged, the product was repeatedly washed with absolute ethanol and pure water three times,...

Embodiment 2

[0041] (1) KH-230 to ZrO 2 Nano particle processing: same as embodiment 1.

[0042] (2) ZrO 2 -Synthesis of g-PDMAEMA: the main synthesis process is the same as in Example 1. The main difference is that the amount of DMAEMA monomer added is 0.05mol.

[0043] (3) PVDF / ZrO 2 - Preparation of g-PDMAEMA hybrid separation membrane (M2): The preparation process is the same as in Example 1, the main difference is that the added ZrO 2 -g-PDMAEMA is the nanoparticle synthesized when the addition amount of DMAEMA monomer is 0.05mol.

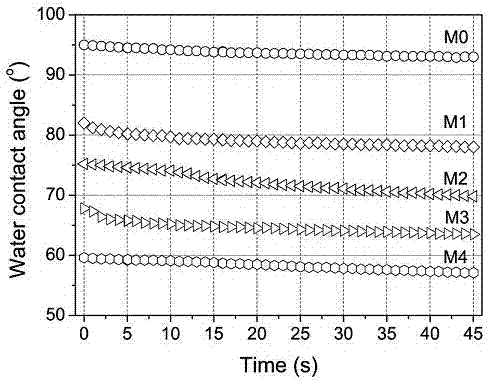

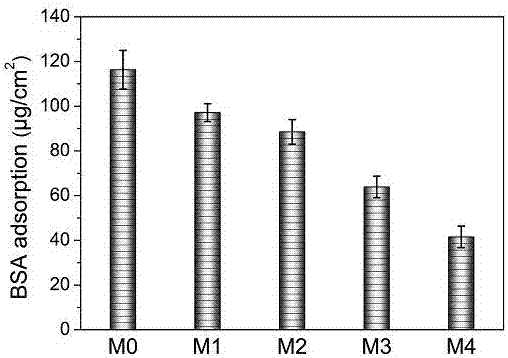

[0044] In this example, the obtained PVDF / ZrO 2 - The initial water contact angle of g-PDMAEMA hybrid membrane M2 is 75º, and the adsorption capacity of BSA is 87μg / cm 2 .

Embodiment 3

[0046] (1) KH-230 to ZrO 2 Nano particle processing: same as embodiment 1.

[0047] (2) ZrO 2 -Synthesis of g-PDMAEMA: the main synthesis process is the same as in Example 1. The main difference is that the amount of DMAEMA monomer added is 0.075mol.

[0048] (3) PVDF / ZrO 2 - Preparation of g-PDMAEMA hybrid separation membrane (M3): The preparation process is the same as in Example 1, the main difference is that the added ZrO 2 -g-PDMAEMA is the nanoparticle synthesized when the addition amount of DMAEMA monomer is 0.075mol.

[0049] In this example, the obtained PVDF / ZrO 2 - The initial water contact angle of g-PDMAEMA hybrid membrane M3 is 68º, and the adsorption capacity of BSA is 64μg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com