Waste leachate recycling treatment system

A landfill leachate recovery treatment technology, applied in the field of landfill leachate recovery and treatment systems, can solve the problems of failure to realize landfill leachate treatment, many carbon sources, and high cost, and achieve the effect of reducing the amount of carbon source dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

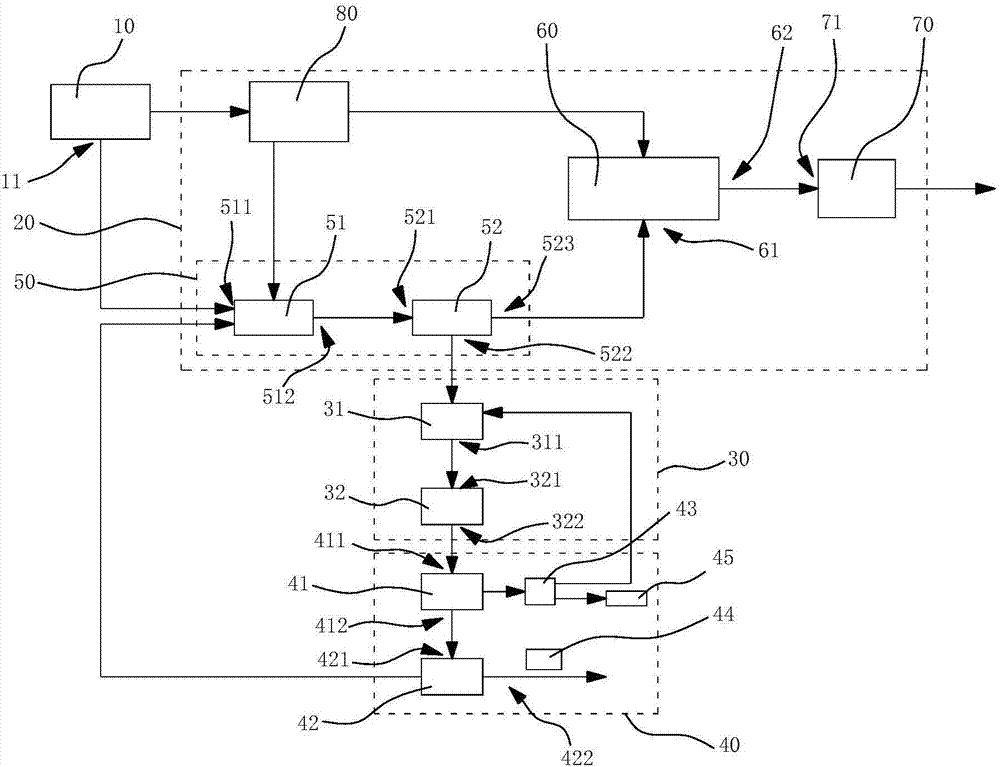

[0008] Such as figure 1 Shown, the present invention provides a kind of recovery treatment system of landfill leachate, comprises leachate tank 10, ammonium fertilizer conversion unit 20, membrane bioreactor 30 and concentrated drying unit 40 arranged in sequence; Ammonium fertilizer conversion unit 20 comprises and The deammonization softening device 50 connected to the liquid outlet 11 of the leachate pool 10, the liquid outlet and the gas outlet of the deammonization softening device 50 are respectively connected to the liquid inlet of the membrane bioreactor 30 and the inlet 61 of the carbonization tower 60 The liquid outlet 62 of the carbonization tower 60 is connected to the feed end 71 of the ammonium bicarbonate separation device 70; the membrane bioreactor 30 includes a biochemical reaction tank 31 and an ultrafiltration unit 32 arranged in sequence, and the feed of the ultrafiltration unit 32 The liquid inlet 321 and the filtrate outlet 322 are respectively connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap