Chalcogenide glass coated with infrared diamond-like protective film and preparation method of chalcogenide glass

A diamond-like film, chalcogenide glass technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of inability to deposit, surface wrinkles, substrate failure, etc., and achieve excellent infrared optical properties, The film base has strong bonding force and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

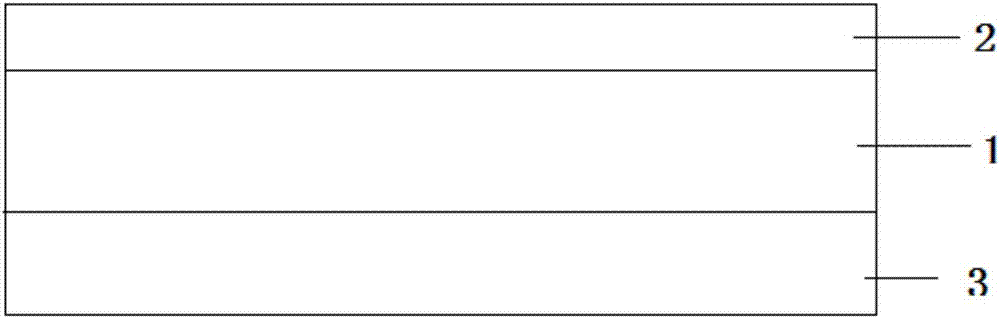

[0028] A method for preparing a chalcogenide glass whose surface is coated with an infrared diamond-like protective film that an embodiment of the present invention proposes comprises:

[0029] 1) Clean the surface of the chalcogenide glass substrate with a mixed liquid of alcohol and ether, put it on the sample stage of the vacuum chamber, adjust the distance between the target and the sample stage, close the baffle between the target and the sample stage, and turn off the vacuum chamber, vacuumize;

[0030] 2) Coating a diamond-like carbon film on the chalcogenide glass substrate by using magnetron sputtering equipment, when the vacuum degree reaches 3×10 -3 When the Pa is below, pass in the working gas, pre-sputter at low power for 10-15 minutes, adjust to the working power, stabilize for 5-10 minutes, open the baffle between the target and the sample stage, and start coating; use gap test Coating, the temperature is controlled below 150°C; the film thickness is controlled...

Embodiment 1

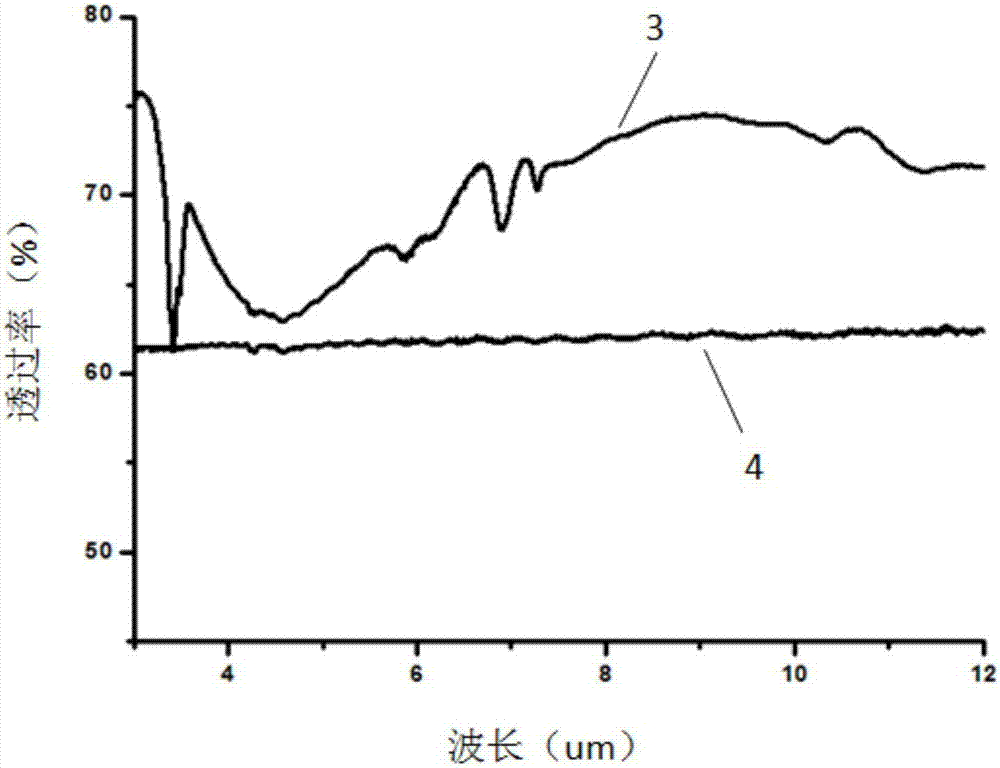

[0039] A kind of preparation method of the chalcogenide glass that one embodiment of the present invention proposes is coated with infrared diamond-like protective film on the surface, select IG6(As 40 Se 60 ) glass is a chalcogenide glass substrate, wipe it with a dust-free cloth dripped with alcohol and ether mixture: the chalcogenide glass substrate is a flat sheet with a size of The transmittance of the chalcogenide glass substrate at 1 μm-11 μm is ≥ 61%, and the density of the above chalcogenide glass substrate is 4.63 g·cm -3 , Glass transition temperature 185±5℃.

[0040] Place the chalcogenide glass substrate on the sample stage of the magnetron sputtering equipment, close the baffle between the sample stage and the target, and pump the vacuum chamber pressure to 3×10 -3 Pa, fill the vacuum chamber with a mixture of high-purity argon and isobutane to 6.5×10 -1 Pa; adjust the RF power to 50W, pre-sputter for 10 minutes, then adjust the RF power to 100W, use interm...

Embodiment 2

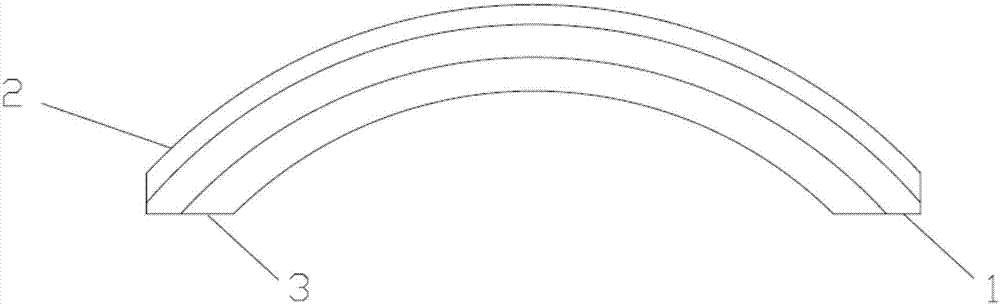

[0048] A kind of preparation method that the surface of a kind of embodiment of the present invention proposes is coated with the chalcogenide glass of infrared diamond-like protective film, select IG2 (Ge 28 Sb 12 Se 60 ) glass, the transmission range of which is 0.8-15 μm when the thickness is 4 mm, the transmission rate of 1-12 μm is ≥ 64%, and the transmission rate of 12-14 μm is ≥ 50%.

[0049] The above-mentioned IG2 glass is processed into a spherical lens with a thickness of 1.0mm and an outer diameter of 37.5mm as a chalcogenide glass substrate; the aperture N=3 of the chalcogenide glass substrate, ΔN=0.5; Wipe with a lint-free cloth of ether mixture.

[0050] Place the chalcogenide glass substrate on the sample stage of the magnetron sputtering equipment, close the baffle between the sample stage and the target, and pump the vacuum chamber pressure to 3×10 -3 Pa, fill the vacuum chamber with a mixture of high-purity argon and methane to 7×10 -1 Pa; adjust the RF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com