In-situ injection remediation method for hexavalent chromium-contaminated soil

A technology of contaminated soil and in-situ injection, applied in the restoration of contaminated soil, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of reducing the concentration of hexavalent chromium and the leaching concentration of trivalent chromium, and achieve strong reducibility , Improve the repair effect, increase the effect of contact chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

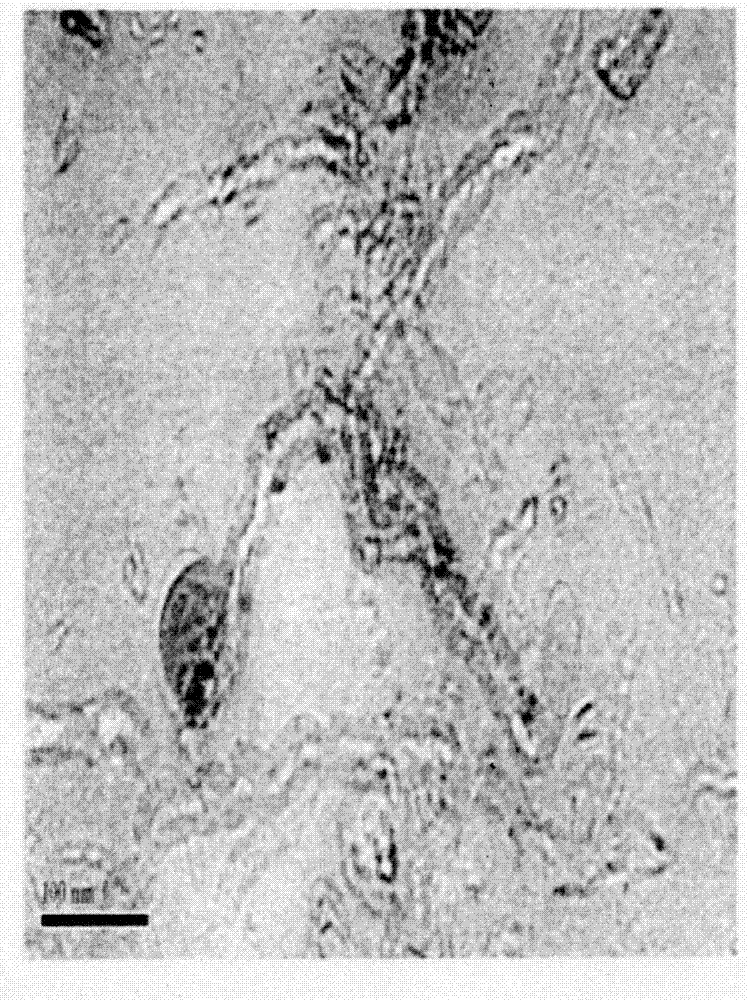

[0034] The preparation method of the carbon nanotubes modified by the crown ether is as follows:

[0035] The first step, the acidification of carbon nanotubes, every 5g of multi-walled carbon nanotubes is placed in the mixed system of hydrochloric acid and sulfuric acid of 50ml, the volume ratio of hydrochloric acid and sulfuric acid is 2: 1, what hydrochloric acid adopts is the concentrated hydrochloric acid of 37%, Sulfuric acid is 98% concentrated sulfuric acid, oscillated in an ultrasonic environment, so that the multi-walled carbon nanotubes are evenly dispersed in the mixed acid, heated to 40°C and stirred for 4 hours, cooled to room temperature, and diluted with deionized water 5 times the volume of the mixed acid , filtered, and the acidified carbon nanotubes were washed 3 times with deionized water to remove the residual acid in the carbon nanotubes, and the product was dried at 70° C. for 24 hours in a vacuum environment of 0.1Mpa to obtain a solid with a smooth surf...

Embodiment 1

[0048] The preparation of embodiment 1 crown ether

[0049] Dissolve 1mol of 2,6-bis(hydroxymethyl)phenol and 1mol of 2,2-dimethylpropane in 50ml of dichloromethane solution, add 0.05mol of trifluoromethanesulfonic acid catalyst, and stir the reaction at room temperature for 2 hours, After filtration, the solution was concentrated on a rotary evaporator to obtain (2,2,6-trimethyl-4H-1,3-benzodioxin-8-methyl)methanol; 1 mol of (2,2, 6-trimethyl-4H-1,3-benzodioxin-8-methyl)methanol was dissolved in 40ml of dichloromethane solution, 1mol of pyridinium chlorochromate was added for acetalization, and the reaction was stirred at room temperature for 1.5 hour, filtered, and the solution was concentrated on a rotary evaporator to obtain (2,2,6-trimethyl-4H-1,3-benzodioxin-8-methyl)formaldehyde; 1mol (2,2, Dissolve 6-trimethyl-4H-1,3-benzodioxin-8-methyl)formaldehyde in 65ml of n-hexane, and pass hydrogen bromide gas at a rate of 80ml per minute to realize deprotection and benzyl brom...

Embodiment 2

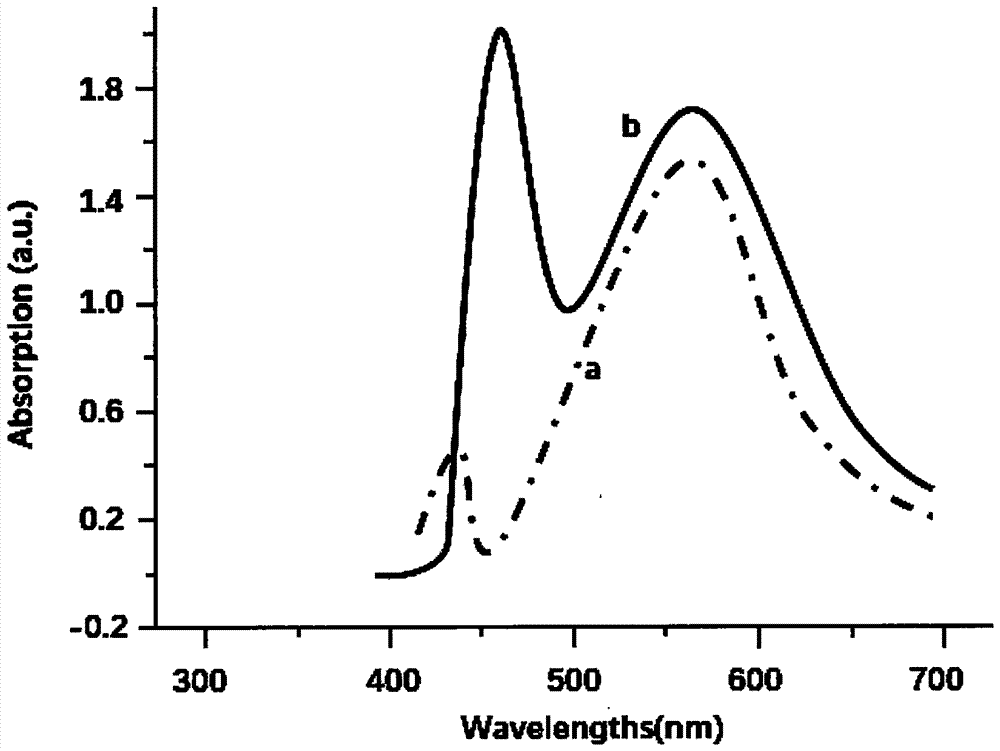

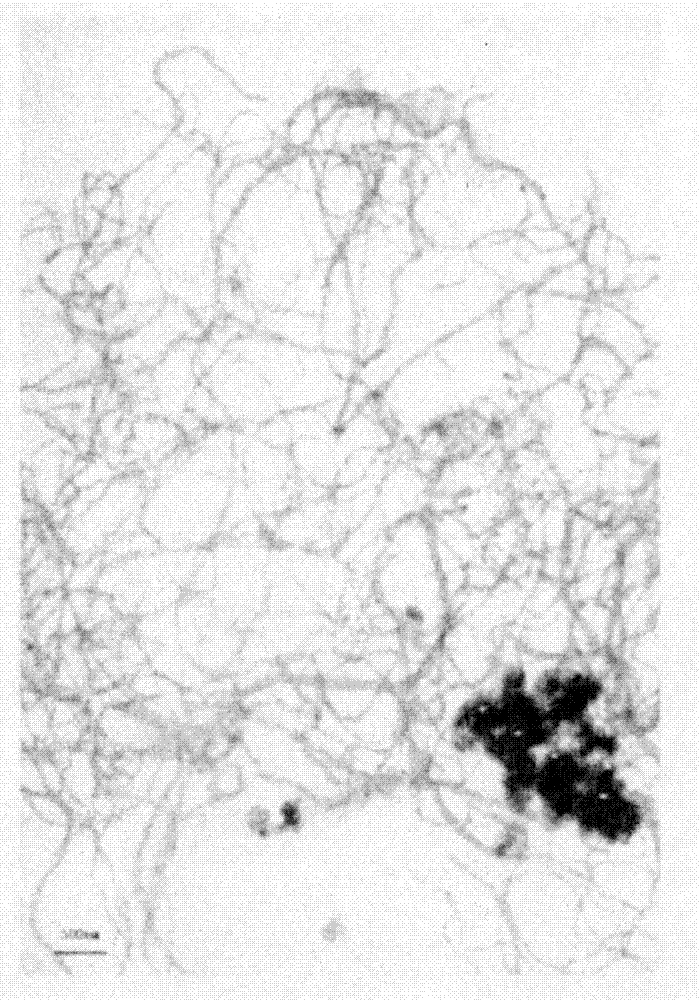

[0052] Embodiment 2 Crown ether modified carbon nanotubes

[0053] Take 5g of multi-walled carbon nanotubes and place them in 50ml of hydrochloric acid and sulfuric acid mixed system. The volume ratio of hydrochloric acid and sulfuric acid is 2:1. Shake the environment to disperse the multi-walled carbon nanotubes evenly in the mixed acid, heat to 40°C and stir for 4 hours, cool to room temperature, add 5 times the volume of the mixed acid to dilute the solution with deionized water, filter, and the carbon nanotubes after acidification are deionized Wash 3 times with water to remove the residual acid in the carbon nanotubes, and dry the product at 70°C for 24 hours under a 0.1Mpa vacuum environment to obtain a solid with a smooth surface; 10g of the crown ether compound prepared in Example 1 was dissolved in N, N-dimethyl In 70ml of methyl formamide, ultrasonically oscillate for 25 minutes to fully dissolve, filter to obtain a yellow solution, add 8g of acidified multi-walled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com