Preparation method for triclosan-containing poly(beta-urethane-urea) and application of triclosan-containing poly(beta-urethane-urea) in selectively killing oral streptococcus mutans of biofilm

A technology of streptococcus mutans and triclosan, which is applied in the field of nano-biomedical materials, can solve problems such as drug leakage, and achieve the effects of improving loading rate, easy mass production, and good biofilm penetration and retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

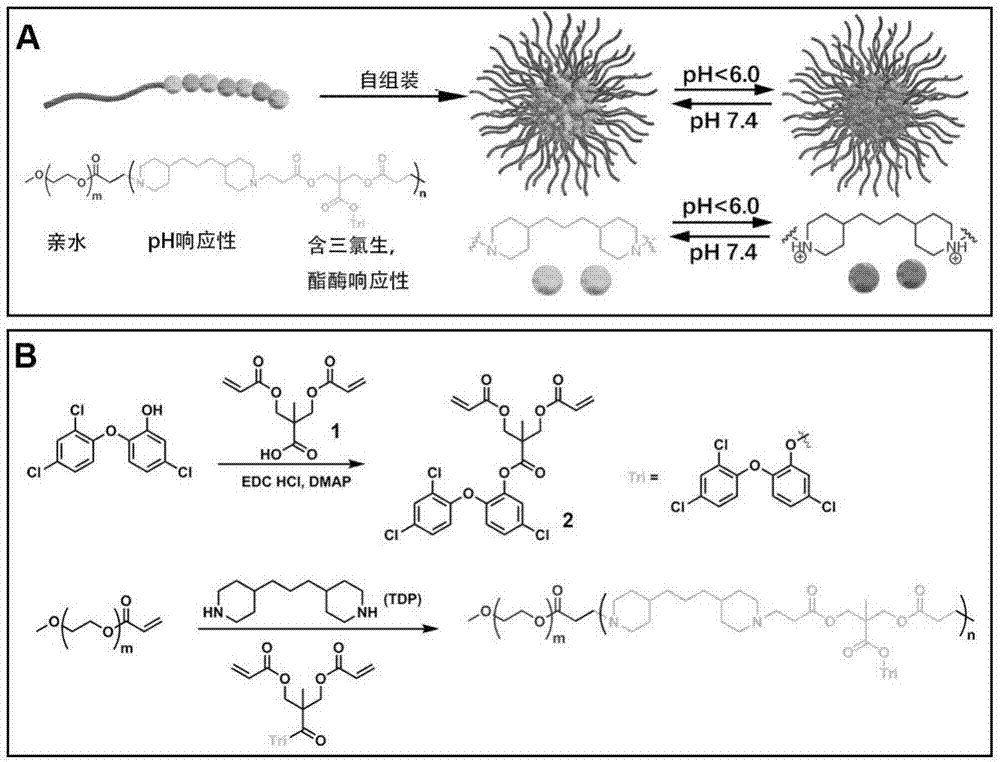

[0031] Embodiment 1: the preparation method of polyethylene glycol-b-poly(β-urethane) polymer micelles containing triclosan

[0032] (1) preparation of monomers containing triclosan, the steps are as follows:

[0033] 1) Add 28.9 grams of triclosan and 31.5 grams of 3-(acryloyloxy)-2-((acryloyloxy)methyl)-2-methylpropionic acid into a dried Schlenk bottle, and add Dissolve it in 200 ml of dichloromethane;

[0034] 2) Add 24.9 grams of EDC·HCl and 15.9 grams of DMAP;

[0035] 3) The system was reacted at room temperature for 12 hours;

[0036] 4) Add 1000 milliliters of dichloromethane to dilute the system after completion of the reaction;

[0037] 5) washing with 1000 milliliters of saturated sodium carbonate solution and 1000 milliliters of dilute hydrochloric acid solution respectively;

[0038] 6) After the organic phase is separated and obtained, it is dried with anhydrous magnesium sulfate, filtered, and the organic solvent is removed in vacuo;

[0039] 7) Purify the...

Embodiment 2

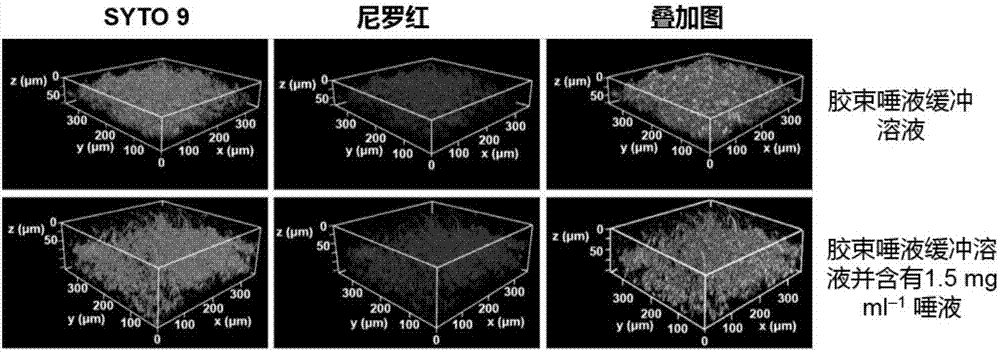

[0050] Example 2: Test experiment of the penetration ability of polyethylene glycol-b-poly(β-urethane) polymer micelles to oral Streptococcus mutans biofilm. The experimental steps of the penetration test are as follows:

[0051] 1) Utilize Streptococcus mutans to cultivate biofilm in 12-well plate for 48 hours;

[0052] 2) using SYTO9 to stain the obtained biofilm sample in the dark for 15 minutes;

[0053] 3) The obtained biofilm sample is mixed with polyethylene glycol-b-poly(β-urethane) polymer micelles containing Nile Red at a concentration of 0.2 mg / ml;

[0054] 4) Incubate at 60 rpm at 37°C for 2 minutes;

[0055]5) The biofilm samples were observed with a TCS SP2 laser confocal fluorescence microscope. Excite SYTO9 and Nile Red with a wavelength of 488 nm, set the receiving wavelength to 490-540 nm (green) and 583-688 nm (red), and set the scan interval to 2 microns;

[0056] 6) The obtained layer-scanned fluorescence micrographs were processed with ImageJ software...

Embodiment 3

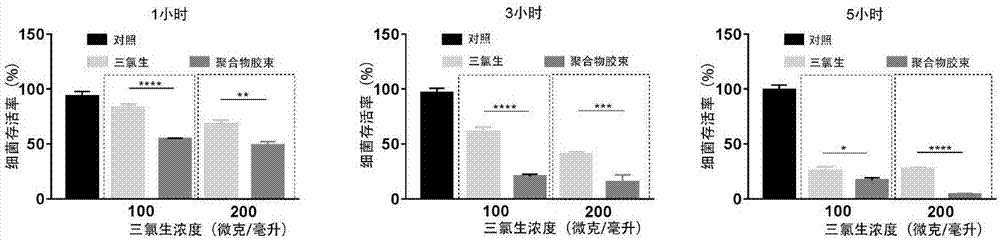

[0058] Example 3: Experiment of selective killing ability of triclosan-containing poly(β-urethane) polymer micelles on oral Streptococcus mutans biofilm.

[0059] Proceed as follows:

[0060] 1) Utilize Streptococcus mutans to cultivate biofilm in 12-well plate for 48 hours;

[0061] 2) Mix freshly prepared polyethylene glycol-b-poly(β-urethane) polymer micelles or triclosan solutions (triclosan concentrations of 100 and 200 μg / ml, respectively, in saliva buffer, pH 6.8) mixing;

[0062] 3) Remove the micellar solution after incubating at 37° C. for 2 minutes at 60 rpm, and then add 300 microliters of saliva buffer;

[0063] 4) After 1 hour, 3 hours and 5 hours, use Live / Dead stain to stain the obtained biofilm sample in the dark for 15 minutes;

[0064] 5) The biofilm samples were observed with a TCS SP2 laser confocal fluorescence microscope. Excited with a wavelength of 488 nm and propidium iodide, the receiving wavelength is set to 490-540 nm (green) and 583-688 nm (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com