CO2 chemical absorption system and method based on water vapor mass transfer reinforced afterheat recovery

A technology of chemical absorption and waste heat recovery, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of large floor area, high investment, and increased heat exchange area, and achieve the reduction of regeneration energy consumption and investment The effect of saving and enhancing the efficiency of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

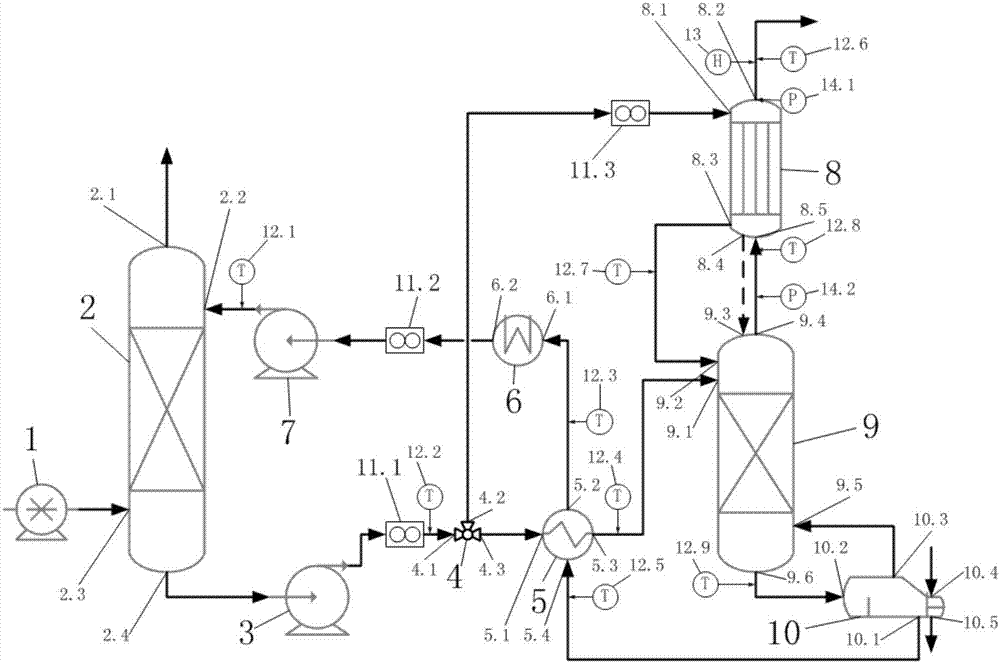

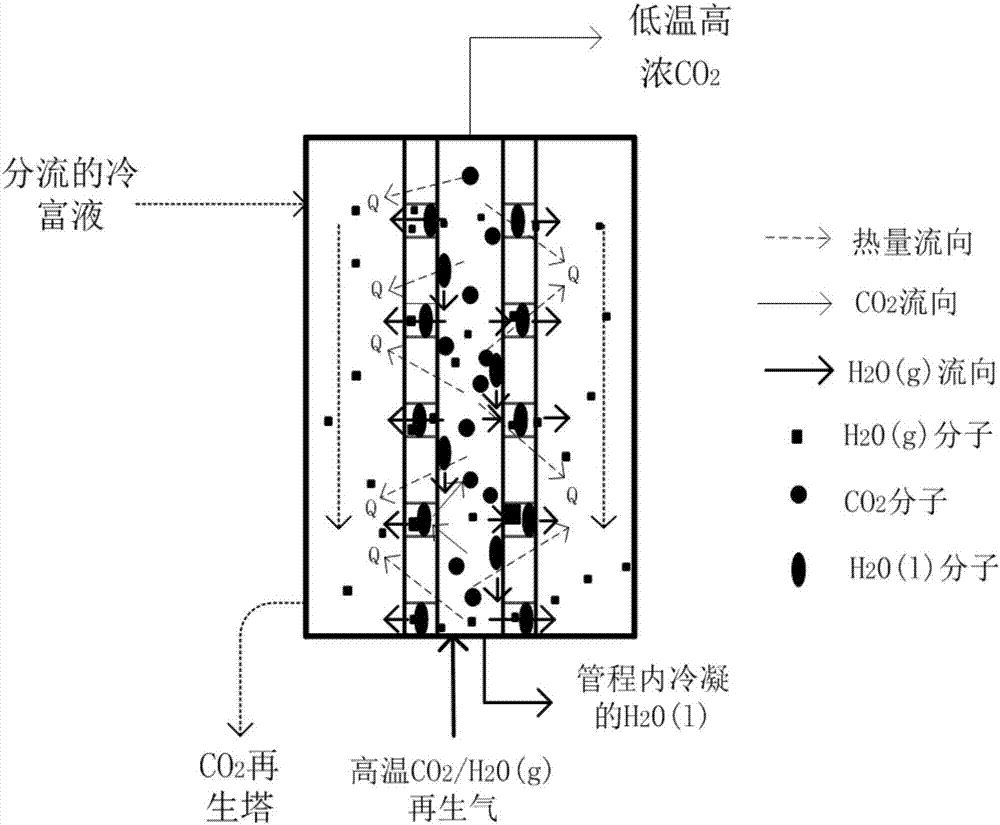

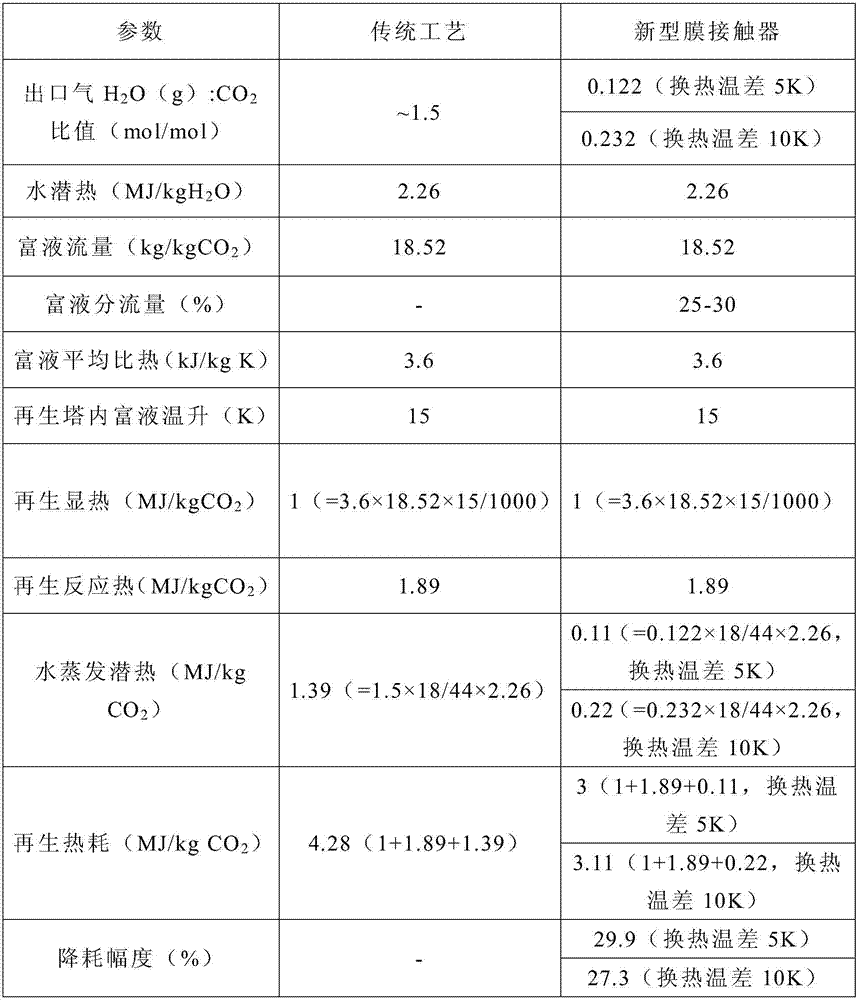

[0020] A CO based on water vapor mass transfer enhanced waste heat recovery 2 chemical absorption system, which includes CO 2 Absorption equipment 2, CO 2 Regeneration equipment 9, reboiler 10, input end and CO 2 The rich solution pump 3 connected to the liquid outlet 2.4 of the absorption device 2, the output end and the CO 2 The lean liquid pump 7 connected to the absorption liquid input port 2.2 of the absorption equipment 2, the lean liquid cooler 6 connected to the input port of the lean liquid pump 7 at the output end, the three-way diverter valve 4, the lean liquid heat exchanger 5, the output end connected to the CO 2 The air inlet 2.3 of the absorption device 2 is connected to the booster fan 1 and the hollow fiber membrane contactor assembly 8, wherein the CO 2 The liquid outlet 2.4 of the absorption device 2 is connected to the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com