Technology and device for quick sulfonation and neutralizing reaction

A sulfonation reactor and sulfonation technology, applied in chemical/physical/physicochemical fixed reactors, pH reactions, series/parallel reactions, etc., can solve the problem that high-viscosity sulfonates are difficult to stir and sulfonates are easy to block , limited cooling capacity, etc., to prevent local oversulfonation and organic matter devolatilization, avoid blockage of pipelines and pumps, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

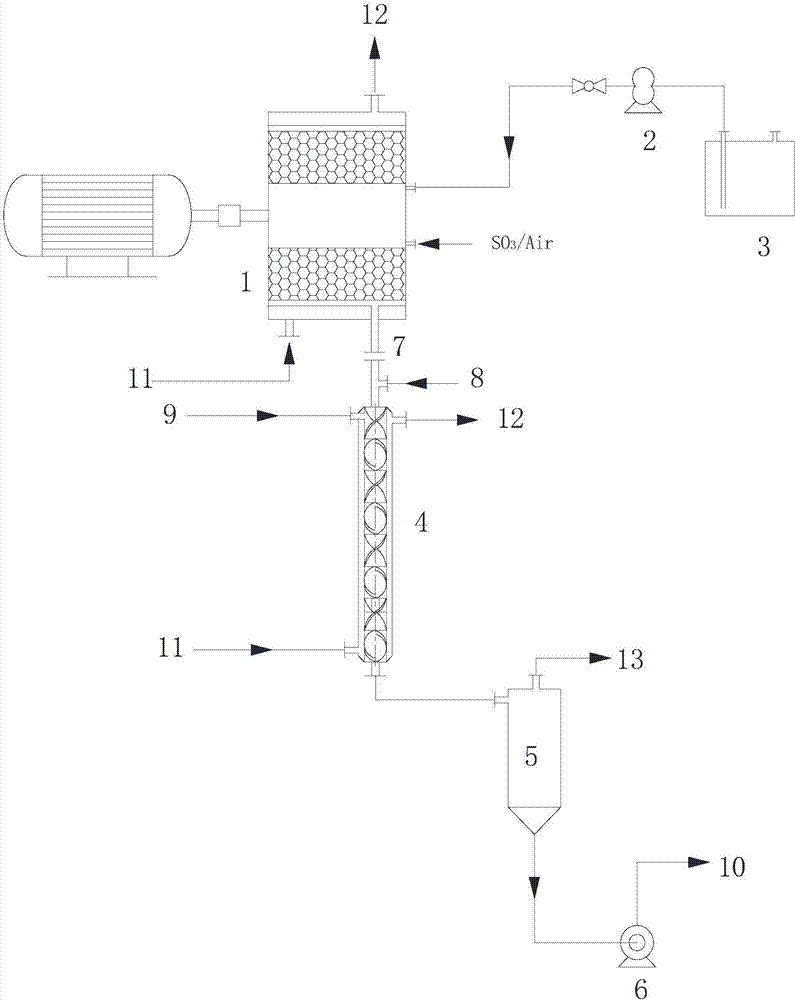

[0018] The device of the present invention comprises a high-gravity sulfonation reactor 1, a raw material storage tank 3, a turbulent flow neutralizer 4, and a gas-liquid separator 5, and is characterized in that the raw material inlet of the high-gravity sulfonation reactor 1 passes through the raw material feed The pump 2 is connected to the raw material storage tank 3, and the bottom outlet of the supergravity sulfonation reactor 1 is connected to the inlet of the turbulent flow neutralizer 4 through the connecting pipe 7, and there is a process water inlet 8 on the connecting pipe 7 for turbulent flow neutralization The upper part of the device 4 has an alkaline water inlet 9, the bottom outlet of the turbulence neutralizer 4 is connected to the gas-liquid separator 5, the product outlet 10 at the bottom of the gas-liquid separator 5 is connected to the discharge pump 6, and the upper part of the gas-liquid separator 5 There is an exhaust port 13, and there are cooling wate...

Embodiment 2

[0021] Under the flow rate of 20kg / h controlled by the metering pump, the rapeseed oil is pumped from the raw material storage tank 3 into the supergravity sulfonation reactor 1 through the raw material pump 2, according to SO 3 The volume ratio is 10%, the gas SO 3 Mix with dry air with a dew point below -50°C, and cool to 45°C to form a mixed gas, according to SO 3 The gas-liquid ratio with the organic raw material is 1.2:1, the mixed gas is continuously fed into the supergravity sulfonation reactor 1, the pressure of the reaction system is 0.3MPa, the SO entering the supergravity sulfonation reactor 3 Rapid reaction with rapeseed oil, the heat generated is transferred through circulating cooling water, and the temperature of the sulfonation reaction is controlled at 80°C. The sulfonated product directly enters the turbulent flow neutralizer 4, and the process water and sodium hydroxide alkaline water respectively enter the turbulent flow neutralizer 4 from the process wate...

Embodiment 3

[0023] Under the flow rate of 50kg / h controlled by the metering pump, phenylnaphthalene is pumped into the supergravity sulfonation reactor 1 from the raw material storage tank 3 by the raw material pump 2, according to SO 3 The volume ratio is 20%, the gas SO 3 Mix with dry air with a dew point lower than -50°C, and cool to 50°C to form a mixed gas, according to SO 3 The gas-liquid ratio with the organic raw material is 1.5:1, the mixed gas is continuously fed into the supergravity sulfonation reactor 1, the pressure of the reaction system is 0.6MPa, the SO entering the supergravity sulfonation reactor 3Rapid reaction with phenylnaphthalene, the heat generated is transferred through circulating cooling water, and the temperature of the sulfonation reaction is controlled at 130°C. The sulfonated product directly enters the turbulent flow neutralizer 4, and the process water and potassium hydroxide alkaline water respectively enter the turbulent flow neutralizer 4 from the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com