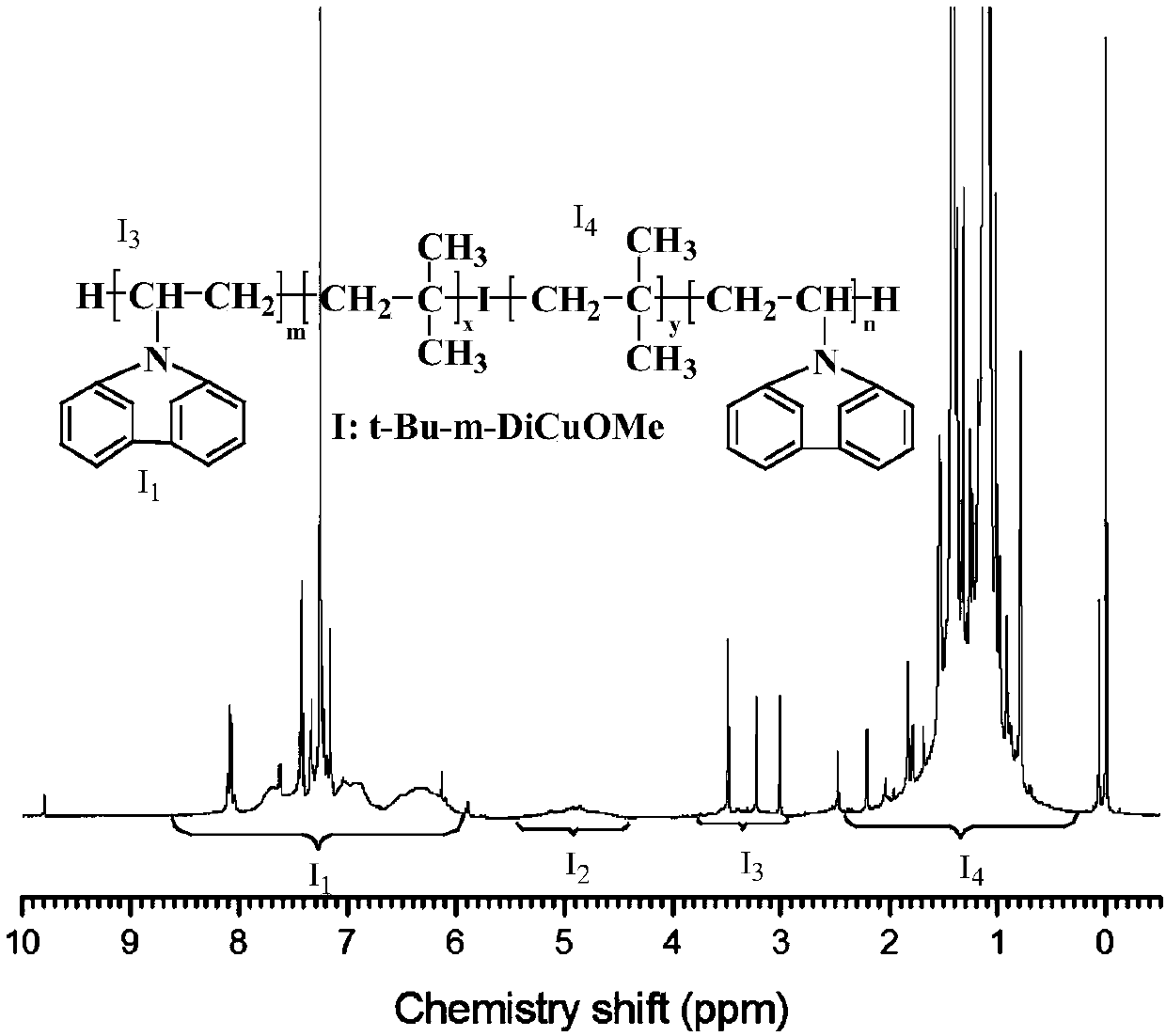

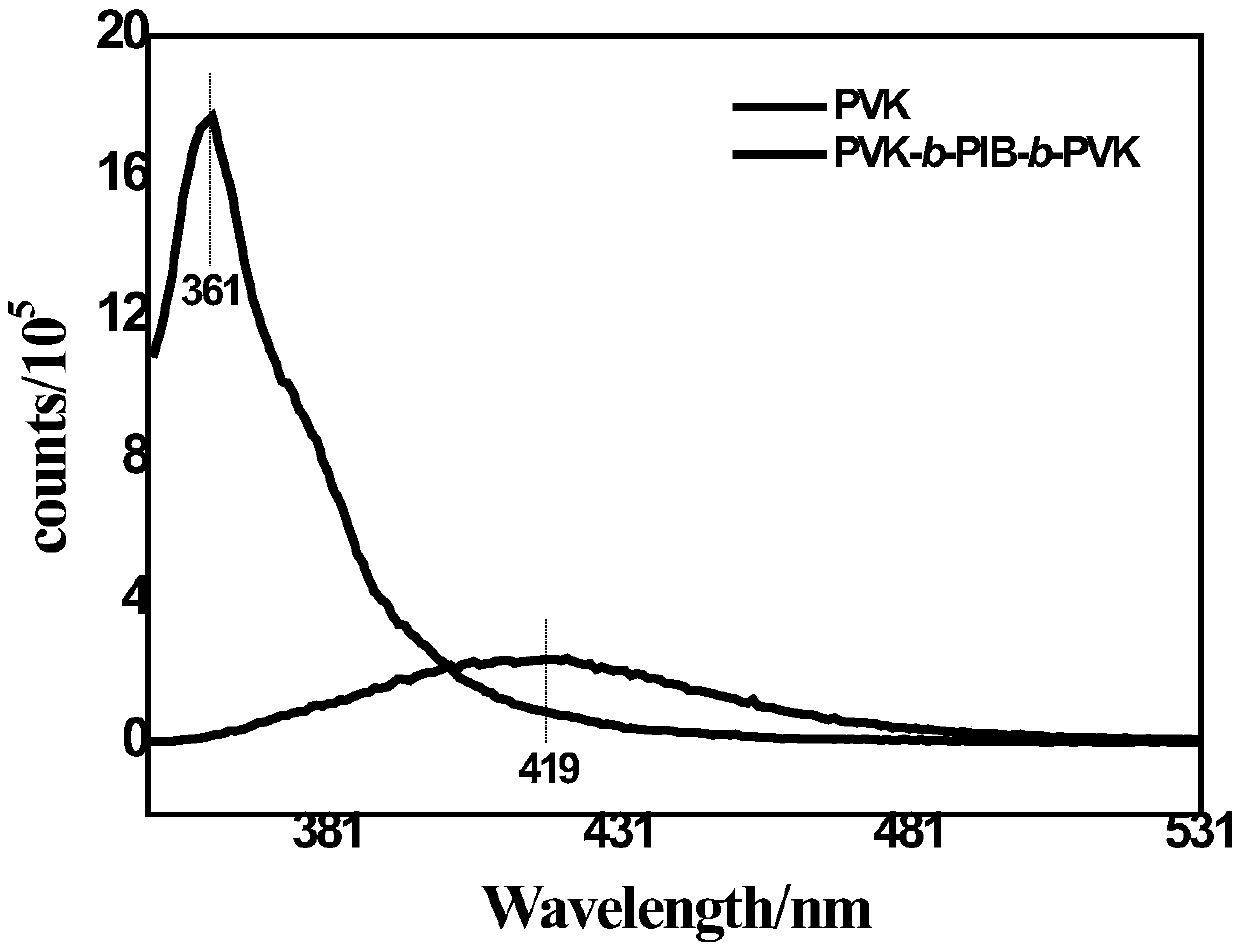

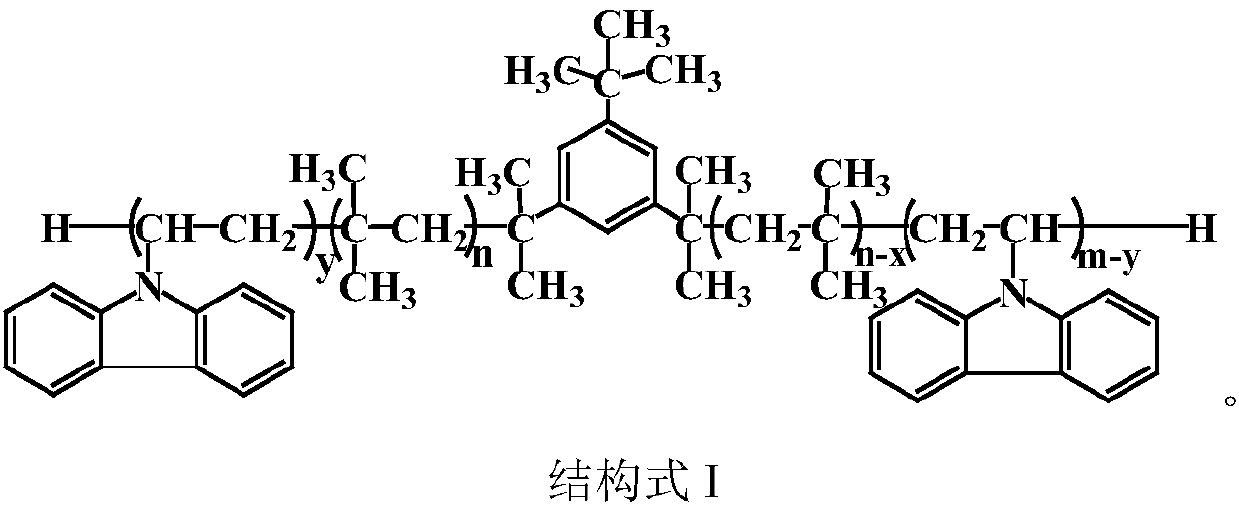

Triblock copolymer of poly-n-vinylcarbazole and polyisobutylene and preparation method thereof

A vinylcarbazole and block copolymer technology, which is applied in the field of triblock copolymers and their preparation, can solve the problems of difficult film formation and weakened fluorescence, and achieves extremely easy film formation, high fluorescence intensity, and increased fluorescence. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Pour cold liquid into the vacuum glove box and cool to the polymerization temperature -100°C, add refluxed n-hexane as a solvent 30ml into the treated polymerization bottle, and mix well; then add the initiator 5-tert-butyl-1, The initiator system composed of 3-bis(1-methoxy-1methylethyl)benzene (0.001M) and co-initiator titanium tetrachloride (0.036M) was aged for 30 minutes, and the intermediate monomer isobutylene was added (IB) (5.33M), after 180 minutes of reaction, add end-capping agent 1,1-diphenylethylene (0.001M), and after 30 minutes of reaction, polyisobutylene with methoxy groups at both ends is obtained; BCl 3 (0.036M), add the hard segment monomer N-vinylcarbazole (NVK) (0.08M), react for 10min, and finally add methanol (CH 3 OH), after terminating the reaction, the solvent was removed from the product, and vacuum-dried at 35° C. to constant weight.

Embodiment 2

[0041] Pour cold liquid into the vacuum glove box and cool to the polymerization temperature -90°C, add 30ml of n-hexane / monochloromethane with a volume ratio of 80 / 20 into the treated polymerization bottle, mix well; then add the initiator 5-tert-butyl-1,3-bis(1-acyloxy-1 methylethyl)benzene (0.0056M) and co-initiator trichlorotriethyldialuminum (0.336M), 6HPy (0.0224M) Initiator system composed of chemical composition, after aging for 15min, add the intermediate monomer isobutylene (20M), after reacting for 150min, add 0.6ml (0.0224M) of end-capping agent 1,1-bis(4-methylphenyl)ethylene, and react Obtain after 40min and have two ends be the methoxy polyisobutene; Add BF in the polyisobutylene of end methoxy 3 (0.336M), add the hard segment monomer N-vinyl carbazole (0.64M) to react for 30min, and finally add methanol (CH 3 OH), after terminating the reaction, the solvent was removed from the product, and vacuum-dried at 35° C. to constant weight.

Embodiment 3

[0043] Pour cold liquid into the vacuum glove box and cool it down to the polymerization temperature -80°C, add 30ml of n-hexane / monochloromethane with a volume ratio of 50 / 50 into the treated polymerization bottle as a solvent, mix well; then add the initiator Initiator composed of 5-tert-butyl-1,3-bis(1-chloro-1methylethyl)benzene (0.00005M) and co-initiator boron trifluoride (0.0006M), EtOAc (0.0004M) System, after aging for 5 minutes, add the intermediate monomer isobutylene (0.64M), add the end-capping agent 1,1-diphenylethylene (0.0004M) after 100 minutes of reaction, and obtain polyisobutylene with methoxy at both ends after 45 minutes of reaction ; Add BF to methoxy-terminated polyisobutene 3 (0.0006M), add the hard segment monomer N-vinyl carbazole (0.047M) to react for 1.5h, and finally add methanol (CH 3 OH), after terminating the reaction, the solvent was removed from the product, and vacuum-dried at 35° C. to constant weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com