Graphene-polydopamine-copper nano-composite material and preparation method thereof

A technology of polydopamine and composite materials, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of complex preparation process, difficult operation, and easy oxidation of nano-copper, and achieve the effect of improving tribological properties and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

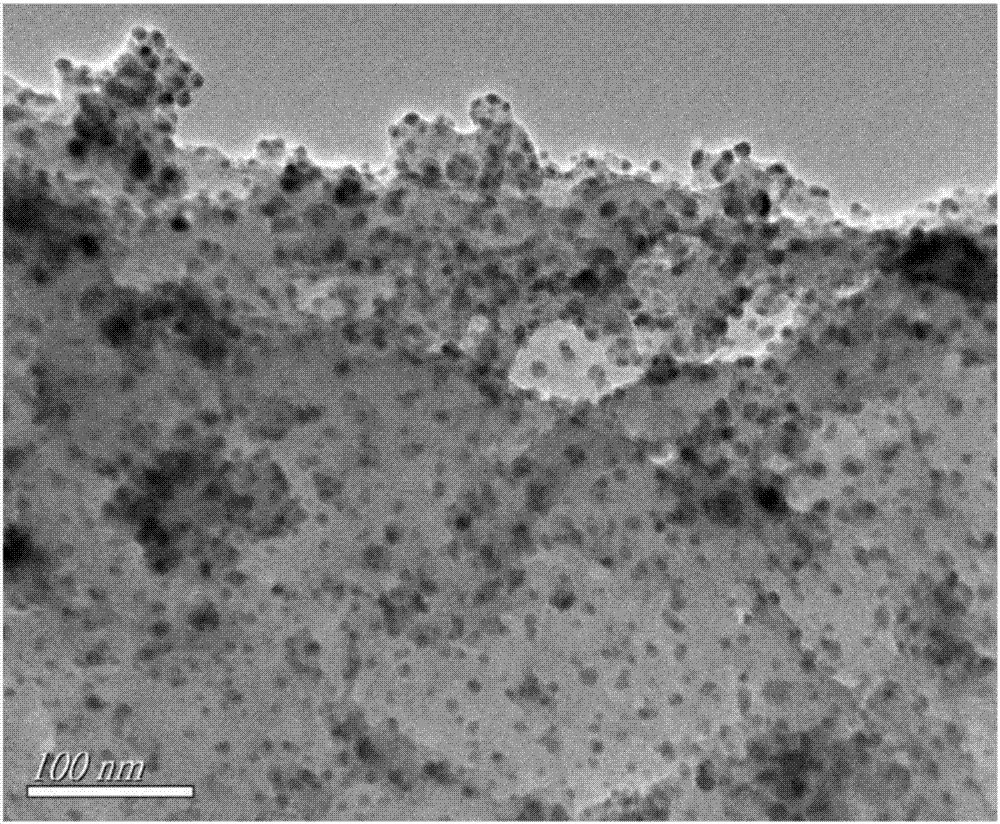

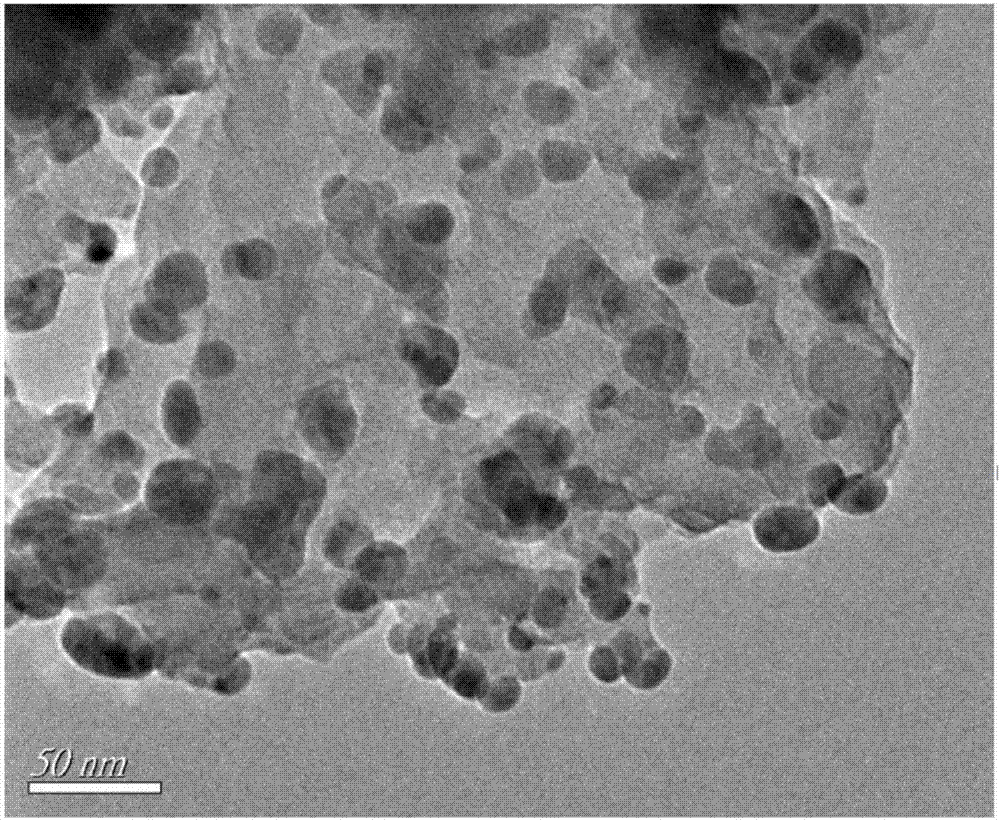

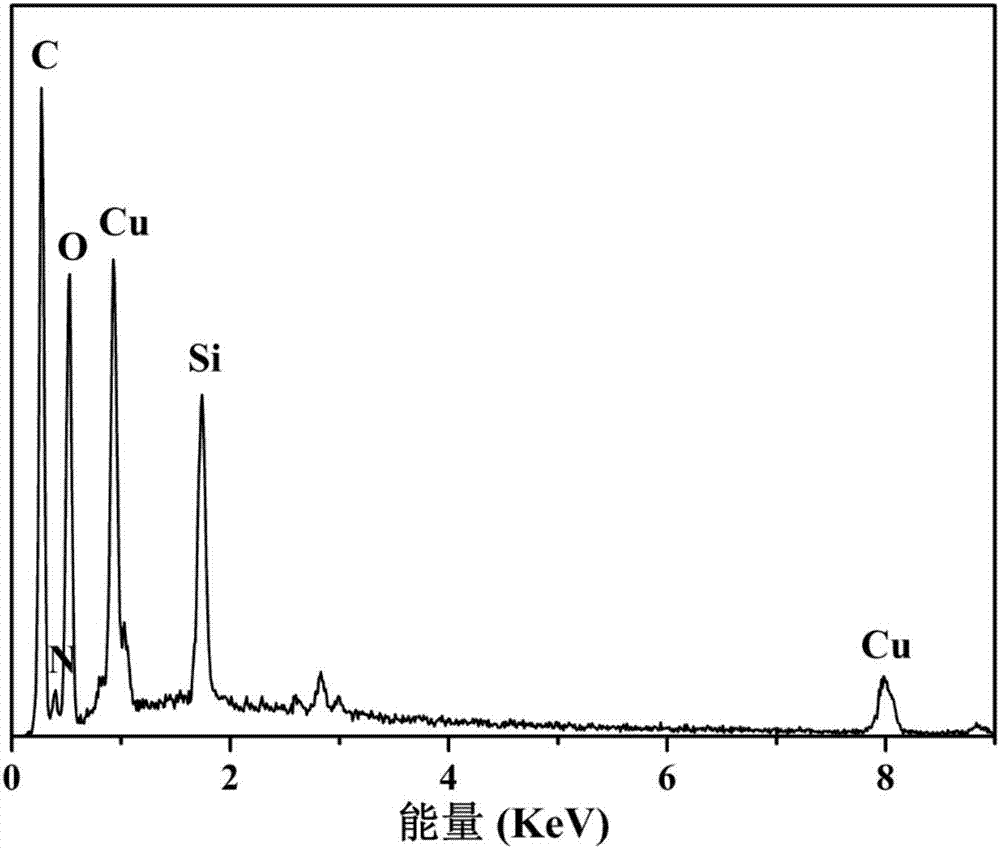

[0025] Step 1, preparation of graphene-polydopamine composite material: Weigh 0.02g of graphene and add it to 200ml of Tris-Hcl buffer solution with PH=8.5, ultrasonically disperse evenly to obtain mixed solution 1, then add 0.4g of dopamine and stir for 24h, A black precipitate was obtained, which was cleaned with distilled water and freeze-dried for 18 hours to obtain a graphene / polydopamine composite material.

[0026] Step 2, prepare graphene-polydopamine-copper nanocomposite material: take 0.005g of the above-mentioned graphene-polydopamine composite material, fully dissolve it in 50ml ethanol solution, and disperse it uniformly by ultrasonic to obtain mixed solution 3, in mixed solution 3 Add 0.05 g of copper acetate and stir evenly. After standing for 12 hours, pour off the supernatant and reconfigure it into a 50 ml solution to obtain mixed solution 4;

[0027] Step 3, dissolving 0.0447 g of sodium hypophosphite into 20 ml of ethanol solution; heating the solution 4 in...

Embodiment 2

[0032] Step 1, preparing graphene-polydopamine composite material: Weigh 0.05g of graphene and add it to 200ml of Tris-Hcl buffer solution with pH=8.5, ultrasonically disperse evenly to obtain mixed solution 1, then add 0.8g of dopamine and stir for 12h, A black precipitate was obtained, which was cleaned with distilled water and freeze-dried for 24 hours to obtain a graphene / polydopamine composite material.

[0033] Step 2, preparing graphene-polydopamine-copper nanocomposite material: take 0.01g of the above-mentioned graphene-polydopamine composite material, fully dissolve it in 50ml ethanol solution, and disperse it uniformly by ultrasonic to obtain mixed solution 3, in mixed solution 3 Add 0.425g of copper chloride and stir evenly, after standing for 12h, pour off the supernatant, and reconfigure it into a 50ml solution to obtain mixed solution 4;

[0034] Step 3, dissolving 0.53 g of sodium hypophosphite into 50 ml of ethanol solution; heating the solution 4 in a water b...

Embodiment 3

[0037] Step 1, preparation of graphene-polydopamine composite material: Weigh 0.1g of graphene and add it to 200ml of Tris-Hcl buffer solution with PH=8.5, ultrasonically disperse evenly to obtain mixed solution 1, then add 0.4g of dopamine and stir for 12h, A black precipitate was obtained, which was cleaned with distilled water and freeze-dried for 24 hours to obtain a graphene / polydopamine composite material.

[0038] Step 2, prepare graphene-polydopamine-copper nanocomposite material: take 0.005 of the above-mentioned graphene-polydopamine composite material, fully dissolve it in 50ml ethanol solution, and ultrasonically disperse evenly to obtain mixed solution 3, and add in mixed solution 3 0.08g of copper sulfate and stir evenly, after standing for 12h, pour off the supernatant, and reconfigure it into a 50ml solution to obtain mixed solution 4;

[0039] Step 3, dissolving 0.106 g of sodium hypophosphite into 50 ml of ethanol solution; heating the solution 4 in a water bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com