Preparation method of color and flavor enhancing proline Maillard reaction product and application

A technology for fragrant proline Maillard and Maillard reaction is applied in the field of preparation of color-enhancing and flavoring proline Maillard reactants, and can solve the problem that cigarettes are difficult to be widely used and no proline Maillard reactants are found. Color enhancement and fragrance appearance and sensory quality, single fragrance type, etc., to achieve the effect of improving appearance and sensory quality, improving appearance and sensory quality, and simple and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

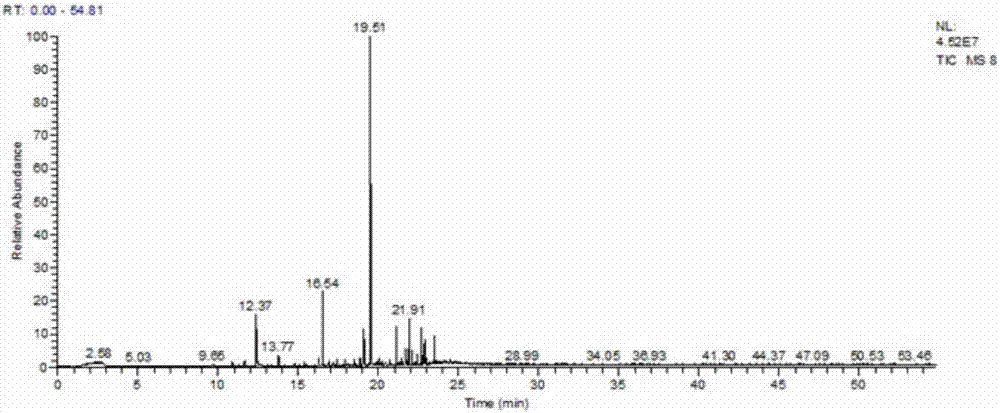

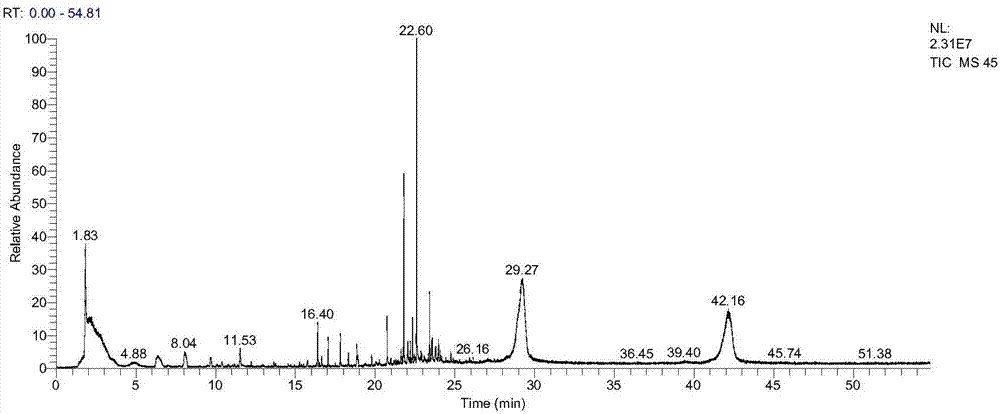

Image

Examples

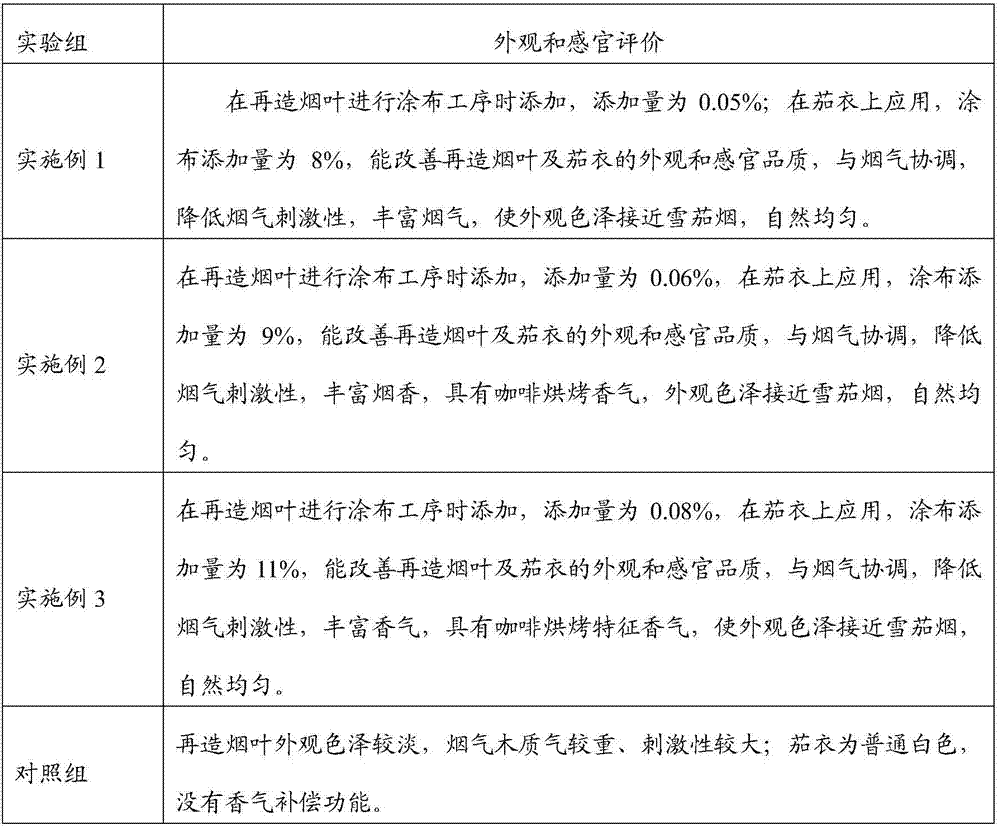

Embodiment 1

[0029]A kind of preparation method of proline Maillard reactant of color-enhancing and aroma-enhancing, specifically comprises the following steps:

[0030] (1) Raw material preparation; Proline and sugar source are used as Maillard reaction substrate, and sugar source is glucose in the present embodiment, by the molar ratio of proline and glucose 3:1, and reaction catalyst is ammoniacal liquor, accounts for Maillard reaction. 0.6% of the mass of the reaction substrate, the mass ratio of water to the reaction substrate is 1.5:1;

[0031] (2) Industrial production: first add water to the reaction tank, start the stirring motor, heat to 50°C, add proline and glucose in turn, and stir thoroughly until they are completely dissolved, then add ammonia water; during the reaction, set the Mela The process conditions of the German reaction tank are temperature 98°C, the stirring motor is kept on, and the reaction time is 6h;

[0032] (3) Finished product: After the reaction, the react...

Embodiment 2

[0035] A kind of preparation method of proline Maillard reactant of color-enhancing and aroma-enhancing, specifically comprises the following steps:

[0036] (1) Raw material preparation; configure according to the mass ratio of proline and fermented coffee extract as 2:1; the reaction catalyst is a certain proportion of ammonia water and vitamin C, accounting for 0.2% of the quality of the above-mentioned proline and fermented coffee extract %, the mass ratio of water and reaction substrate is 2.8:1;

[0037] (2) Industrial production: first add water to the reaction tank, start the stirring motor, heat to 55°C, add proline and fermented coffee extract in turn, stir thoroughly until completely dissolved, then add catalyst ammonia water and vitamin C ( The mass ratio is 1:0.5); during the reaction process, the process condition of the Maillard reaction tank is set to a temperature of 125°C, the stirring motor is kept on, and the reaction time is 7h;

[0038] (3) Finished prod...

Embodiment 3

[0042] A kind of preparation method of proline Maillard reactant of color-enhancing and aroma-enhancing, specifically comprises the following steps:

[0043] (1) Raw material preparation; proline and complex sugar source are configured according to a mass ratio of 3:1, and the complex sugar source is a compound of xylose and fermented coffee bean extract in an equal mass ratio; the reaction catalyst is ammonia water, α -tolualdehyde, accounts for 2% of Maillard reaction substrate quality, and the mass ratio of water and reaction substrate is 4.2:1;

[0044] (2) Industrial production: first add water to the reaction tank, start the stirring motor, heat to 58°C, add proline and complex sugar sources in a certain proportion in turn, stir fully, and then add the catalyst until it is completely dissolved; the reaction process , set the process conditions of the Maillard reaction tank at a temperature of 165°C, keep the stirring motor turned on, and the reaction time is 8 hours;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com