Method for preparing zinc oxide nano thin film under low-temperature condition and application of zinc oxide nano thin film

A zinc oxide nanotechnology, low temperature technology, applied in zinc oxide/zinc hydroxide, nanotechnology and other directions, can solve problems such as safety hazards, and achieve the effects of high safety, mild reaction conditions, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

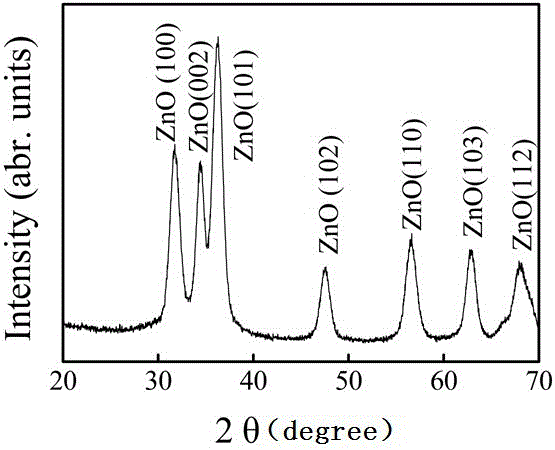

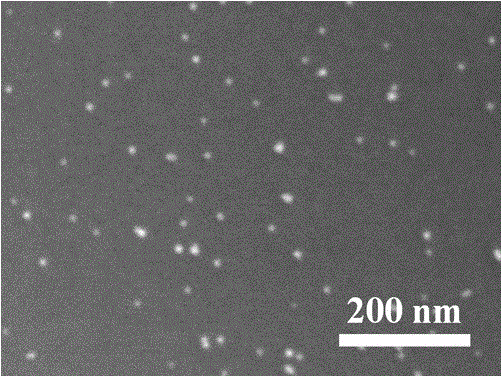

[0031] Embodiment 1, a kind of method for preparing zinc oxide nano film under low temperature condition, it comprises the steps:

[0032] a. Weigh 150mg of zinc acetate dihydrate and mix with 70ml of absolute ethanol, seal the mixture and place it in a water bath, stir it magnetically for 30min at a water bath temperature of 40°C, and prepare acetic acid with a concentration of 9mmol / L Ethanol solution of zinc, denoted as solution A

[0033] b. Weigh 400mg of sodium hydroxide and dissolve it in 10ml of deionized water to obtain a sodium hydroxide solution with a concentration of 1mol / L, then add the sodium hydroxide solution to 40ml of absolute ethanol to obtain a concentration of 0.2mol The ethanol solution of sodium hydroxide in / L is denoted as solution B;

[0034] c. Add solution B prepared in step b to solution A dropwise, the volume ratio of solution B to solution A is 0.5:7 to obtain mixed solution C;

[0035] d. Seal the mixed solution C obtained in step c and place...

Embodiment 2

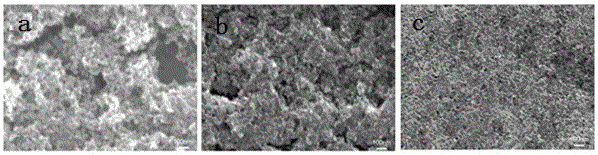

[0039] Embodiment 2, a kind of method for preparing zinc oxide nano film under low temperature condition, it comprises the steps:

[0040] a. Weigh 108mg of zinc acetate dihydrate and mix it with 70ml of absolute ethanol. After the mixture is sealed, it is placed in a constant temperature water bath at 30°C and stirred magnetically for 60 minutes. It is prepared into an ethanol solution of zinc acetate with a concentration of 7mmol / L. as solution A

[0041] b. Weigh 800mg of sodium hydroxide and dissolve it in 10ml of deionized water to obtain a sodium hydroxide solution with a concentration of 2mol / L, then add the sodium hydroxide solution to 40ml of absolute ethanol to obtain a concentration of 0.4mol The ethanol solution of sodium hydroxide in / L is denoted as solution B;

[0042] c. Add solution B prepared in step b to solution A drop by drop, the volume ratio of solution B to solution A is 1:7, and mixed solution C is obtained;

[0043] d. Seal the mixed solution C obta...

Embodiment 3

[0047] Embodiment 3, a kind of method for preparing zinc oxide nano film under low temperature condition, it comprises the steps:

[0048] a. Weigh 230mg of zinc acetate dihydrate and mix them with 70ml of absolute ethanol. After the mixture is sealed, place it in a constant temperature water bath at 60°C and stir it magnetically for 10 minutes. It is prepared into an ethanol solution of zinc acetate with a concentration of 15mmol / L. as solution A

[0049] b. Weigh 1g of sodium hydroxide and dissolve it in 10ml of deionized water to obtain a sodium hydroxide solution with a concentration of 2.5mol / L, then add the sodium hydroxide solution to 40ml of absolute ethanol to obtain a concentration of 0.5 The ethanol solution of the sodium hydroxide of mol / L is denoted as solution B;

[0050] c. Add solution B prepared in step b to solution A drop by drop, the volume ratio of solution B to solution A is 0.1:7 to obtain mixed solution C;

[0051] d. Seal the mixed solution C obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com