All-fiber passive Q-switched pulsed fiber laser

A fiber laser, pulsed laser technology, applied in the field of laser technology and fiber, can solve the problems of unstable performance, unsuitability, low optical uniformity and low light damage threshold, achieve compact structure, improve energy density, and improve bleaching switching capability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

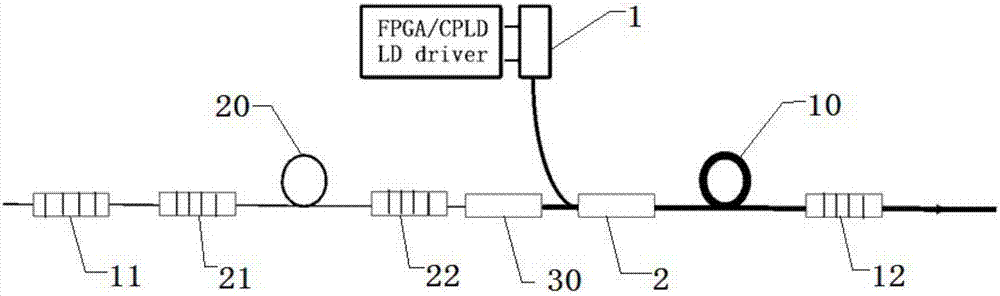

[0026] Such as figure 1 As shown, the first embodiment is a 10xxnm all-fiber passive Q-switched pulsed fiber laser, including: 9xxnm (915nm, 920nm, 940nm, 950nm, 980nm, etc.) pump source (Pump LD) 1, pump beam combiner ( PBC) 2, the first reflector 11 of the first resonant cavity, the second reflector 12 of the first resonant cavity, the first reflector 21 of the second resonant cavity, the second reflector 22 of the second resonant cavity, the doping of the first resonant cavity Gain fiber 10 , second cavity doped gain fiber 20 and mode field matcher (MFA) 30 . Wherein, the pump source (Pump LD) 1 fiber output end is connected to the pump end of the pump beam combiner (PBC) 2, and the signal output end of the pump beam combiner is connected to one end of the first resonant cavity doped gain fiber 10, The other end of the first resonator-doped gain fiber 10 is connected to the second reflector 12 of the first resonator; the signal input end of the pump beam combiner is then c...

Embodiment 2

[0042] The second embodiment includes all the technical features in the first embodiment, and the difference is that the first resonator-doped gain fiber and the second resonator-doped gain fiber in the second embodiment both use erbium-ytterbium co-doped double-clad fibers, Wherein the first resonator-doped gain fiber 10 is Nufern 10 / 125 erbium-ytterbium co-doped double-clad fiber, the second resonator-doped gain fiber 20 is Nufern 6 / 125 erbium-ytterbium co-doped double-clad fiber, and the The wavelength of the laser with the first wavelength in the first resonant cavity is 1535 nm, and the corresponding laser with the second wavelength in the second resonant cavity has a wavelength of 1650 nm.

[0043] In other embodiments, the first resonator-doped gain fiber and the second resonator-doped gain fiber can also be single-clad, double-clad or multi-clad active fibers doped with rare earth elements such as thulium-doped fiber.

Embodiment 3

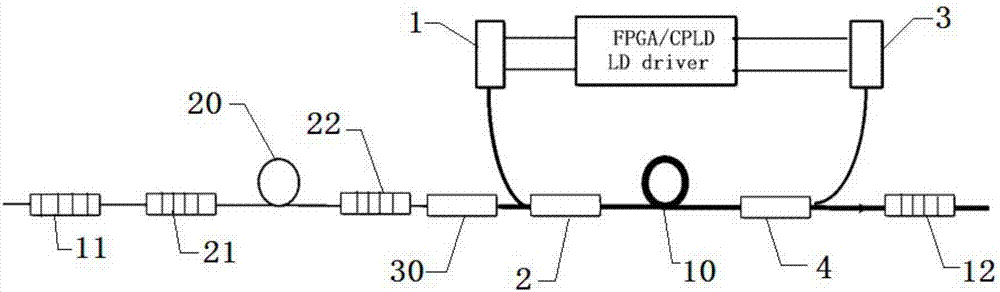

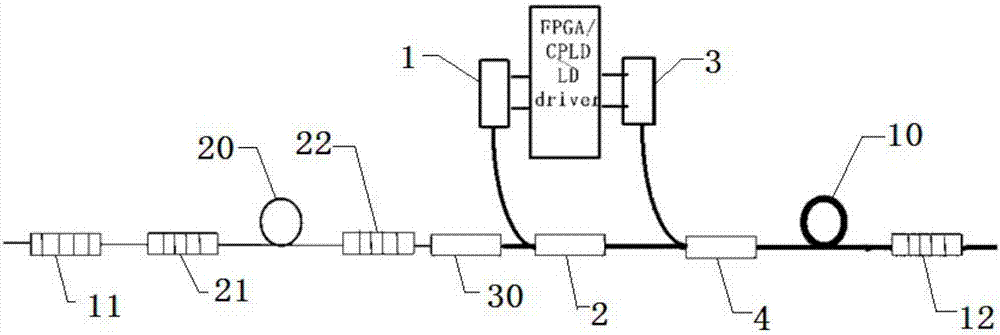

[0045] Such as figure 2 As shown, the second embodiment includes all the technical features of the first embodiment. The difference is that the pumping structure in this embodiment is a bidirectional pumping structure in which two pumping directions exist simultaneously, and another pumping source 3 and Another pump beam combiner 4, the two pump sources and the pump beam combiner form the bidirectional pumping of the first resonant cavity doped gain fiber, and the pump light wavelength and power of the two pump sources are the same or different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com