A postharvest drying method of salvia miltiorrhiza

A drying method and technology of salvia miltiorrhiza, applied in the direction of static material dryer, partial agitation dryer, drying, etc., can solve the problems of uneven moisture content of dry products, high equipment configuration requirements and cost, loss of active ingredients, etc., to achieve Prevent the loss of high active ingredients, improve the quality of medicinal materials, and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

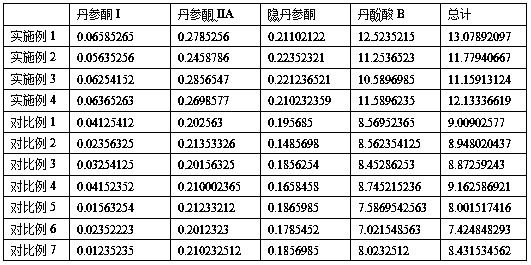

Examples

Embodiment 1

[0029] The postharvest drying method of salvia miltiorrhiza, the steps are:

[0030] 1) Pretreatment: Harvested fresh salvia miltiorrhiza, remove soil, fibrous roots, and rinse;

[0031] 2) Grading: Plants removed from diseases are classified according to the weight of the salvia miltiorrhiza plant: the first grade is more than 450 grams, the second grade is 250-450 grams, and the third grade is less than 250 grams;

[0032] 3) Ultraviolet irradiation: put the Danshen graded in step 2) under an intensity of 5 kJ m -2 Under the ultraviolet light irradiation, the irradiation time is: 4 hours for the first grade, 3 hours for the second grade, and 2.5 hours for the third grade;

[0033] 4) Drying: dry the Danshen plants treated in step 3) at 25-30°C for 24 hours;

[0034] 5) Spray methyl jasmonate: Spray the Salvia miltiorrhiza plants treated in step 4) at 25-30°C for 10 -5 mol / L methyl jasmonate-ethanol solution until the salvia miltiorrhiza plant is wet and the liquid drips; ...

Embodiment 2

[0038] The postharvest drying method of salvia miltiorrhiza, the steps are:

[0039] 1) Pretreatment: Harvested fresh salvia miltiorrhiza, remove soil, fibrous roots, and rinse;

[0040] 2) Grading: Plants removed from diseases are classified according to the weight of the salvia miltiorrhiza plant: the first grade is more than 450 grams, the second grade is 250-450 grams, and the third grade is less than 250 grams;

[0041] 3) Ultraviolet irradiation: put the Danshen graded in step 2) under an intensity of 5 kJ m -2 Under the ultraviolet light irradiation, the irradiation time is: 3.5h for the first level, 3h for the second level, and 2.5h for the third level;

[0042] 4) Drying: put the salvia miltiorrhiza plants treated in step 3) in the air at 25-30°C for 48 hours;

[0043] 5) Spray methyl jasmonate: Spray the Danshen plants treated in step 4) at 25-30°C for 10 -5 mol / L methyl jasmonate-ethanol solution until the methyl jasmonate wets the Salvia miltiorrhiza plant and t...

Embodiment 3

[0047] The postharvest drying method of salvia miltiorrhiza, the steps are:

[0048] 1) Pretreatment: Harvested fresh salvia miltiorrhiza, remove soil, fibrous roots, and rinse;

[0049] 2) Grading the plants to remove the disease, according to the weight of the salvia miltiorrhiza plant: the first grade is more than 450 grams, the second grade is 250-450 grams, and the third grade is less than 250 grams;

[0050] 3) Ultraviolet irradiation: put the Danshen graded in step 2) under an intensity of 5 kJ m -2 Under the ultraviolet light irradiation, the irradiation time is: 2.5h for the first level, 2.5h for the second level, and 2.5h for the third level;

[0051] 4) Drying: put the Danshen plants treated in step 3) in the air at 25-30°C for 72 hours;

[0052] 5) Spray methyl jasmonate: Spray the Danshen plants treated in step 4) at 25-30°C for 10 -5 mol / L methyl jasmonate-ethanol solution until the salvia miltiorrhiza plant is wet and the liquid drips;

[0053] 6) Second dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com