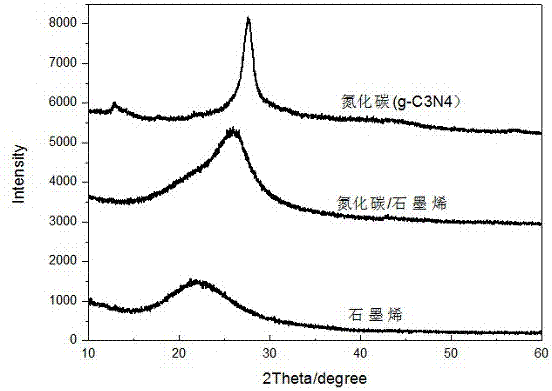

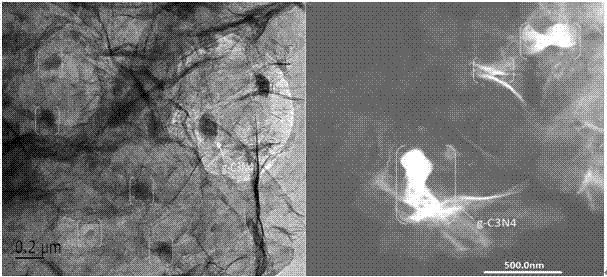

Preparation method of carbon nitride/graphene composite material with three-dimensional structure

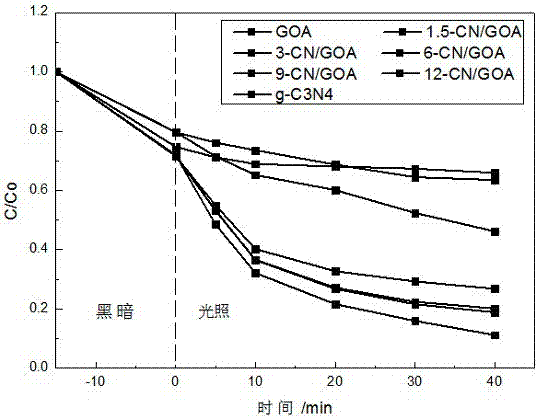

A composite material, three-dimensional structure technology, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low degree of separation of photogenerated electrons and holes, small specific surface area, and large band gap problem, to achieve the effect of improving photocatalytic performance, simple process, and increased agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of a three-dimensional carbon nitride / graphene composite material, characterized in that it specifically comprises the following steps:

[0025] (1). Prepare graphene oxide (GO) by the Hummers method; take a certain volume of graphene oxide solution, dilute it with water to a concentration of 3mg / ml, and stir for 1h to obtain a graphene oxide (GO) solution;

[0026] (2). Preparation of carbon nitride (g-C3N4) nanosheets:

[0027] (2-1). Put 5 g of dicyandiamide into a muffle furnace and raise the temperature to 550°C and keep it warm for 4 hours to obtain carbon nitride (g-C 3 N 4 );

[0028] (2-2). The above obtained carbon nitride (g-C 3 N 4 ) was added to 100mL of concentrated sulfuric acid H 2 SO 4 The solution was stirred for 24h under a stirrer; then, under ice-bath conditions, 1g of sodium nitrate (NaNO 3 ) and 10g of potassium permanganate (KMnO 4 ) and stirred for 10h; then diluted with 140mL of deionized water and 60mL of hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com