Combined collector for feldspar and quartz flotation separation and application method

A combination of collector and feldspar technology, applied in flotation, solid separation, etc., can solve problems such as difficult to obtain concentrate products, high mutual content of products, unsatisfactory separation effect, etc., achieve good flotation separation effect, improve Separation efficiency, effect of reducing magnetic agglomeration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The main minerals of a non-metallic mine in Shaanxi are potassium feldspar, albite, and quartz, with a content of 35%, 32%, and 31% respectively. There are also a small amount of magnetite, titanomagnetite, and maghemite in the ore ;The particle size of quartz is generally coarse, and a small part is metasomatized along the edge and middle of potassium feldspar, so it is not easy to dissociate completely; A small part of the particle size is extremely fine.

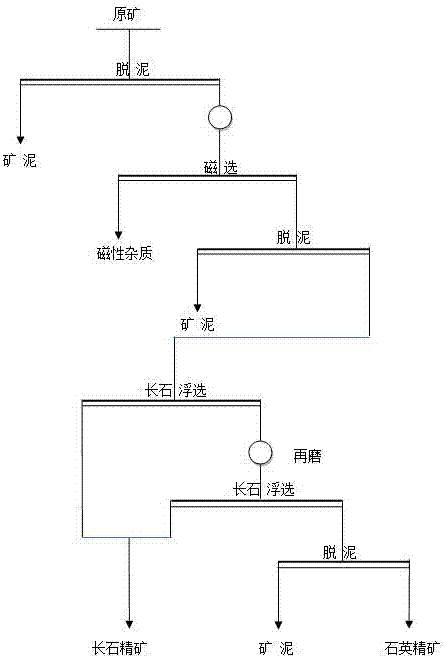

[0022] The ore feldspar and quartz separation process is as follows:

[0023] 1) Raw ore desliming: feed the crushed raw ore into a single-chamber free-settling grading box for sedimentation and desliming, remove the slime with a particle size of <0.01mm, and obtain raw ore grit products;

[0024] 2) Grinding of grit products: Wet grind the raw ore grit products obtained from desliming to a fineness of 45% and a grinding concentration of 50%;

[0025] 3) Magnetic separation: Feed the wet-milled ore pulp into the ...

Embodiment 2

[0030] The main minerals in the flotation tailings of a sulfur beneficiation plant in Gansu are quartz, plagioclase, biotite, and pyrrhotite, with contents of 77%, 20%, 1.5%, and 0.85%, respectively, and a small amount of chlorite, Magnetite, pyrrhotite; plagioclase argillization phenomenon is relatively serious, and the particle size distribution is wide, and the thickness is uneven; most of the quartz particle size is coarse and uniform, and a small part is metasomatized from the plagioclase core. tiny.

[0031] The ore feldspar and quartz separation process is as follows:

[0032] 1) Raw ore desliming: feed the crushed raw ore into a single-chamber free-settling grading box for sedimentation and desliming, remove the slime with a particle size of <0.01mm, and obtain the raw ore grit products;

[0033] 2) Grinding of grit products: Wet grind the raw ore grit products obtained from desliming to a fineness of 50% and a grinding concentration of 55%;

[0034] 3) Magnetic sepa...

Embodiment 3

[0039] The main minerals of a non-metallic mine in Guangdong are quartz, potassium feldspar, plagioclase, and a small amount of albite, biotite, magnetite, limonite, pyrite, garnet, etc. Quartz, potassium feldspar The contents of plagioclase and plagioclase are 54%, 39%, and 5% respectively. Potassium feldspar has a fine particle size and is partly muddy. The plagioclase has a wide particle size range, ranging from 2mm to 0.016mm; the quartz particle size is generally coarse.

[0040] The ore feldspar and quartz separation process is as follows:

[0041] 1) Raw ore desliming: feed the crushed raw ore into a single-chamber free-settling grading box for sedimentation and desliming, remove the slime with a particle size of <0.01mm, and obtain raw ore grit products;

[0042] 2) Grinding of grit products: Wet grind the raw ore grit products obtained from desliming to a fineness of 55% and a grinding concentration of 45%;

[0043] 3) Magnetic separation: Feed the wet-milled ore pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com